High Pressure Filter Press Centrifugal Slurry Pump

- Payment Type:

- L/C, T/T, D/P

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shijiazhuang |

|---|---|

| Payment Type: | L/C, T/T, D/P |

Product Description

Product Description

1.1 Product Introduction:

The MH & MHE high head slurry pumps are specifically designed to combat the need to run conventional design slurry pumps at excessive speeds to generate high heads often required in many modern slurry pumping applications. Single pump unit rather than series pumping can be adopted, at greatly reduced capital cost, while still offering optimum wear life and efficiency.

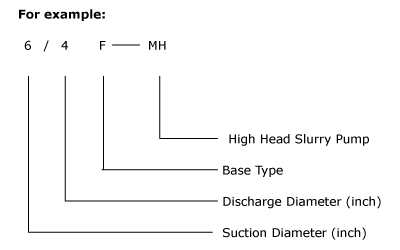

1.2 Notation:

1.3 Product Features:

- Wear resistant metal wet end parts, long service life

- High efficiency

- High head & high pressure

- Discharge branch can be positioned at intervals of 45 degrees

- Can be installed in multistage series

- Easy to maintain

1.4 Application Range:

Size: 25mm to 150mm

Capacity: up to 1025 m3/h

Maximum head: up to 100 m

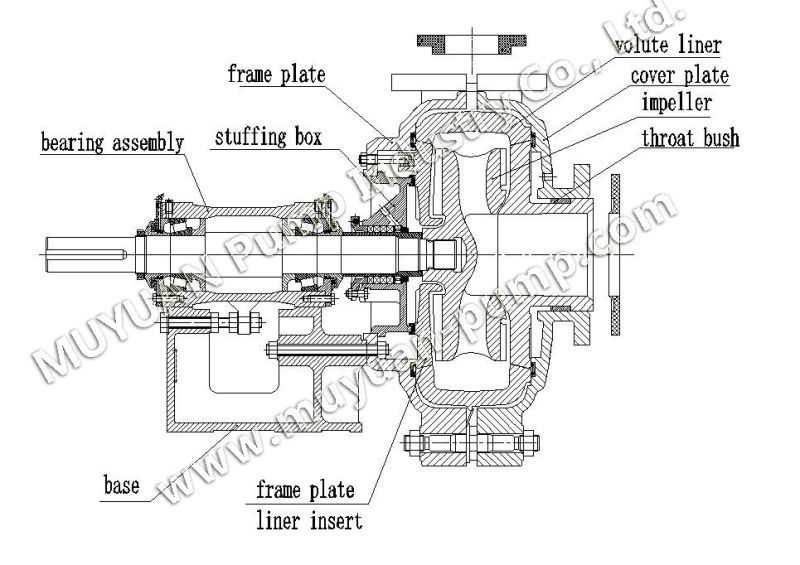

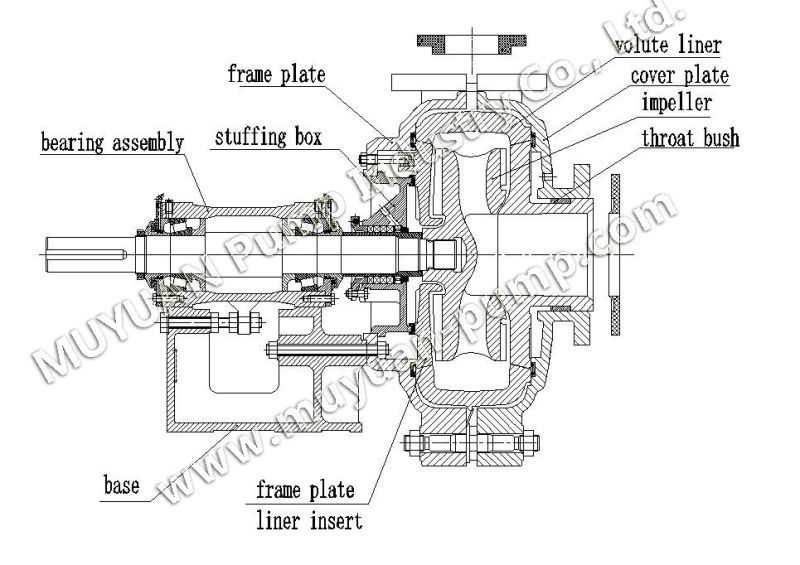

1.5 Pump Construction:

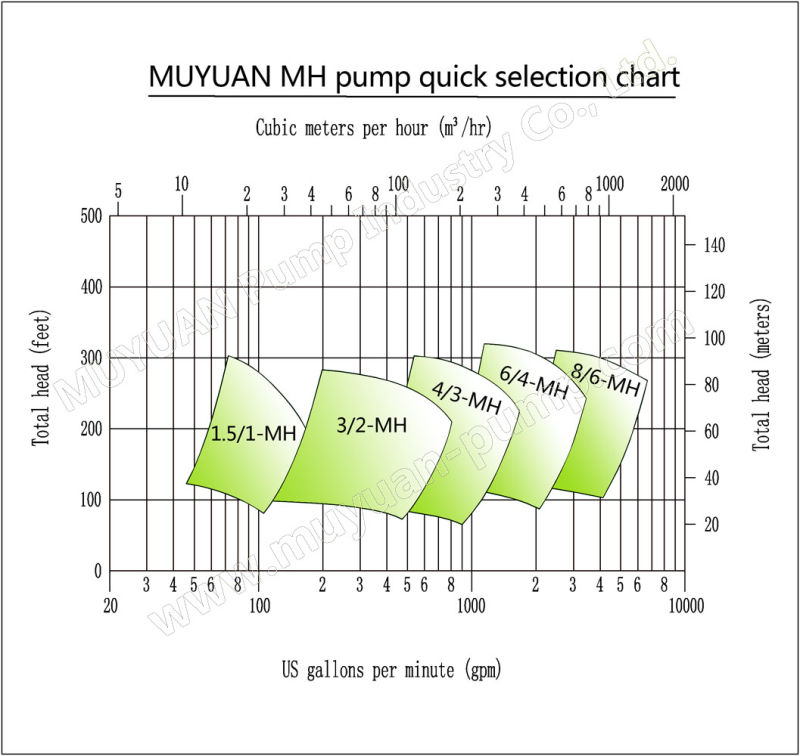

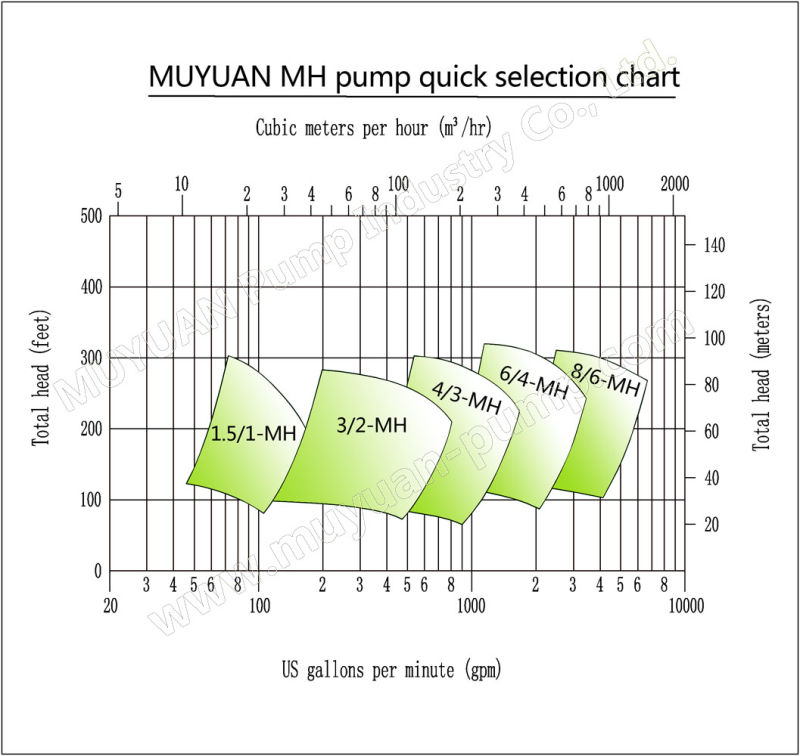

1.6 Pump Selection Chart:

1.6 Pump Selection Chart:

The MH & MHE high head slurry pumps are specifically designed to combat the need to run conventional design slurry pumps at excessive speeds to generate high heads often required in many modern slurry pumping applications. Single pump unit rather than series pumping can be adopted, at greatly reduced capital cost, while still offering optimum wear life and efficiency.

1.2 Notation:

1.3 Product Features:

- Wear resistant metal wet end parts, long service life

- High efficiency

- High head & high pressure

- Discharge branch can be positioned at intervals of 45 degrees

- Can be installed in multistage series

- Easy to maintain

1.4 Application Range:

Size: 25mm to 150mm

Capacity: up to 1025 m3/h

Maximum head: up to 100 m

1.5 Pump Construction:

1.6 Pump Selection Chart:

1.6 Pump Selection Chart:

| Pump Type | Pump Model | Size | Flow | Head | Application | Feature |

| MH High Head Slurry Pump |

1.5/1C-MH | 1"-6" | 16-1125 m3/h | 12-95m | –Filter Press Feed | –Wear resistant metal wet end parts, |

| –Ball Mill Discharge | long service life | |||||

| 3/2D-MH | –Rod Mill Discharge | –High efficiency | ||||

| –Coarse Sand/Tailing | –High head & high pressure | |||||

| 4/3E-MH | –Mineral Concentrate | –Discharge branch can be | ||||

| –Heavy Media | positioned at intervals of 45 degrees | |||||

| 6/4F-MH | –Waste Water | –Can be installed in multistage series | ||||

| –Coal | –Easy to maintain | |||||

| 8/6G-MH | –Flotation | |||||

| –Fine Tailing |

Related Keywords

Related Keywords

You May Also Like

You May Also Like