Centrifugal Horizontal Anti Wear Heavy Duty Slurry Pump

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T, D/P, Paypal, Money Gram, Western Union |

Product Description

Product Description

1.1 Product Introduction:

Pump type MM is the standard middle duty slurry pump which designed for the continuous pumping of highly abrasive, high density slurries with minimal maintenance requirements. Pump type ML is the standard light duty slurry pump which designed for the continuous pumping of light abrasive, light density slurries with minimal maintenance requirements. They maintain high efficiencies over the wear life of its components and typically used in process plant transfers, wet waste processes, recycling-washing plants, sand plant duties, heavy minerals processing, mineral recovery and chemical process plant.

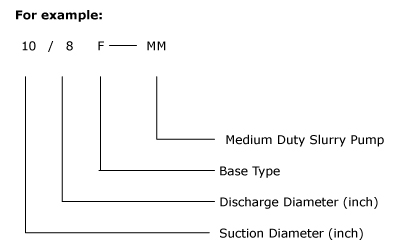

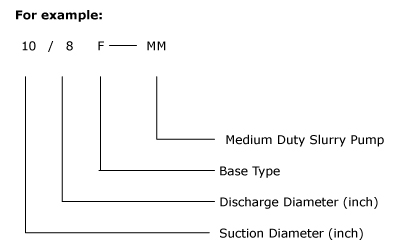

1.2 Notation:

1.3 Product Features:

-Wear resistant metal or rubber wet end parts, long service life

-Wide options for impeller

-Various types of pump seals to suit different working condition

-Grease or oil lubrication

-Discharge branch can be positioned at intervals of 45 degree

-Can be installed in multistage series

-Easy to maintain

1.4 Technical Parameters:

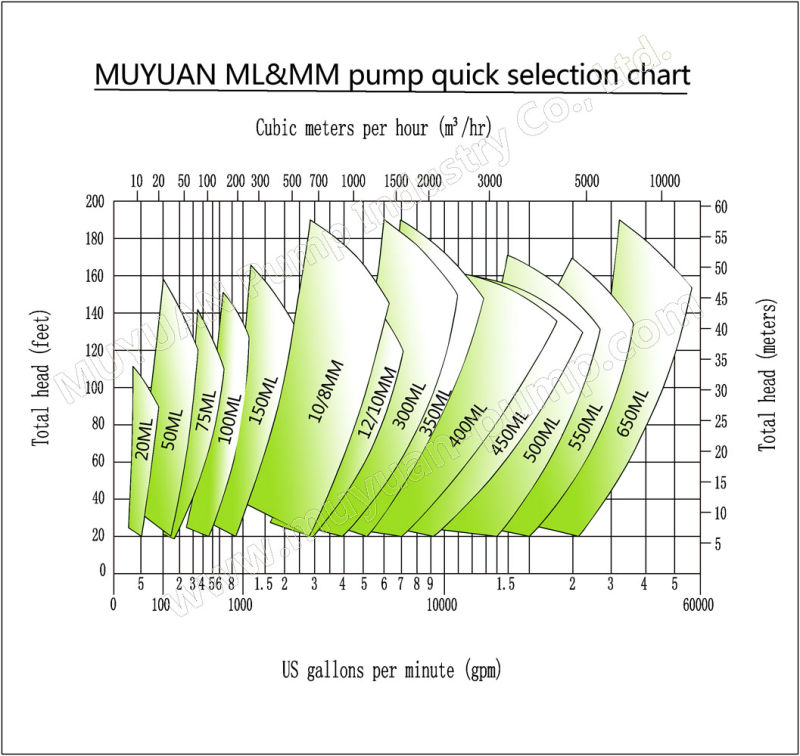

Size range (discharge): 20 mm to 650 mm

Capacities: to 10,225 m3/hr

Heads: to 55 m

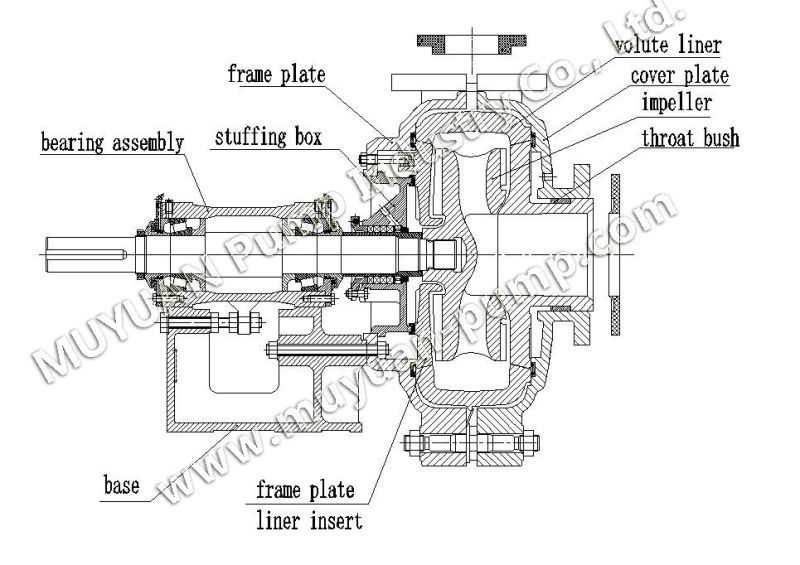

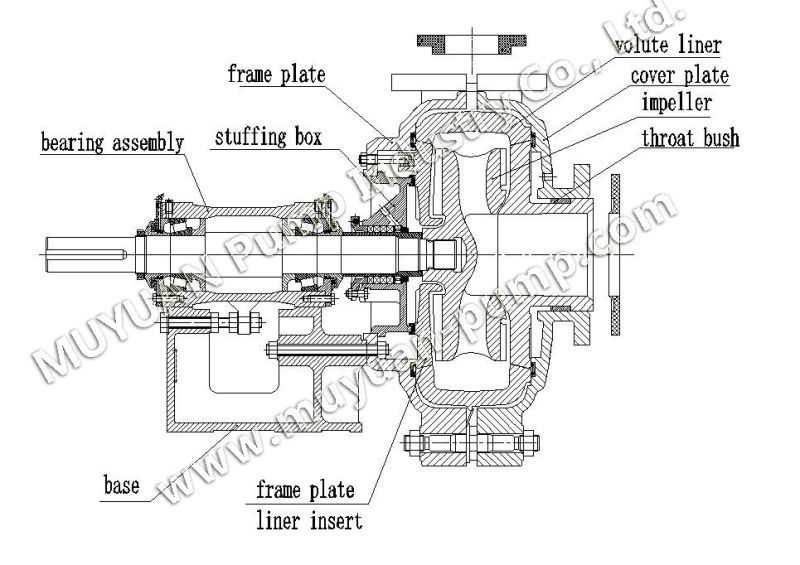

1.5 Pump Construction:

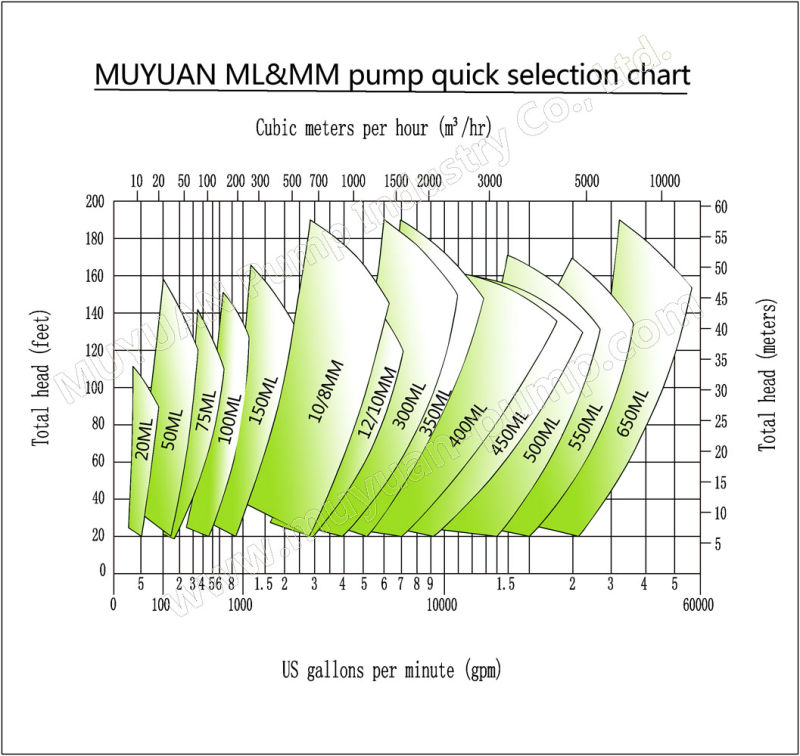

1.6 Pump Selection Chart:

1.6 Pump Selection Chart:

Pump type MM is the standard middle duty slurry pump which designed for the continuous pumping of highly abrasive, high density slurries with minimal maintenance requirements. Pump type ML is the standard light duty slurry pump which designed for the continuous pumping of light abrasive, light density slurries with minimal maintenance requirements. They maintain high efficiencies over the wear life of its components and typically used in process plant transfers, wet waste processes, recycling-washing plants, sand plant duties, heavy minerals processing, mineral recovery and chemical process plant.

1.2 Notation:

1.3 Product Features:

-Wear resistant metal or rubber wet end parts, long service life

-Wide options for impeller

-Various types of pump seals to suit different working condition

-Grease or oil lubrication

-Discharge branch can be positioned at intervals of 45 degree

-Can be installed in multistage series

-Easy to maintain

1.4 Technical Parameters:

Size range (discharge): 20 mm to 650 mm

Capacities: to 10,225 m3/hr

Heads: to 55 m

1.5 Pump Construction:

1.6 Pump Selection Chart:

1.6 Pump Selection Chart:

| Pump Type | Pump Model | Size | Flow | Head | Application | Feature |

| MM/ML Medium Duty Slurry Pump Light Duty Slurry Pump |

20A-ML | 20 - 650mm | 3-12000 m3/h | 4-60m | –Ball Mill Discharge | –Wear resistant metal or |

| 50B-ML | –Rod Mill Discharge | rubber wet end parts | ||||

| 75C-ML | –Coarse Sand | long service life | ||||

| 100D-ML | –Coarse Tailing | –Wide options for impeller | ||||

| 150E-ML | –Mineral Concentrate | –Various types of pump seals | ||||

| 10/8E-MM | –Heavy Media | to suit different working condition | ||||

| 10/8F-MM | –Coal | –Grease or oil lubrication | ||||

| 10/8R-MM | –Flotation | –Discharge branch can be | ||||

| 12/10F-MM | –Fine Tailing | positioned at intervals of 45 degree | ||||

| 300S-ML | –Process Chemical | –Can be installed in multistage series | ||||

| 350S-ML | –Pulp and Paper | –Easy to maintain | ||||

| 400ST-ML | –FGD | |||||

| 450ST-ML | –Waste Water | |||||

| 550TU-ML | –Oil Sand |

Related Keywords

Related Keywords

You May Also Like

You May Also Like