Slurry Pump (300EZ-A70)

- Payment Type:

- L/C, T/T, D/P

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T, D/P |

Product Description

Product Description

Slurry Pump (300EZ-A70)

1. Introduction:

The EZ series mining slurry pumps are designed as single-stage, single-suction centrifugal pumps. They are classified into the horizontal version (EZ type) and vertical version (EZL type) according to mode of construction and the discharge diameters of horizontal pumps vary from 300mm to 200mm 150mm, 100mm, 80mm, 65mm, 50mm, 40mm, etc. And the discharge diameters of vertical pumps vary from 150mm to 100mm 80mm 65mm 50mm, etc.

The centrifugal pumps are innovative in both hydraulic and structural designs. The wet parts are made from self-developed high-chrome alloy cast iron with high wear-resistance. They are of energy- saving, high efficiency, little vibration, low noise, long service, lightweight, reliable operation and easy maintenance.

2. Application:

Series EZ slurry pumps are widely used in the mining, coal washery, power plant, metallurgy, petrochemical, building material, dredging and other industrial departments, etc. It is used in the various working sites including hydrocyclone feeding pump, magnetic separator feeding pump, underflow slurry pump (thickener underflow pump, filter separator underflow pump), flotation feeding pump, vibrating sieve feeding pump, shaking grading pressure pump, concentrate pump, and tailing pump.

3. Model Explanation:

300EZ-A70

1. Introduction:

The EZ series mining slurry pumps are designed as single-stage, single-suction centrifugal pumps. They are classified into the horizontal version (EZ type) and vertical version (EZL type) according to mode of construction and the discharge diameters of horizontal pumps vary from 300mm to 200mm 150mm, 100mm, 80mm, 65mm, 50mm, 40mm, etc. And the discharge diameters of vertical pumps vary from 150mm to 100mm 80mm 65mm 50mm, etc.

The centrifugal pumps are innovative in both hydraulic and structural designs. The wet parts are made from self-developed high-chrome alloy cast iron with high wear-resistance. They are of energy- saving, high efficiency, little vibration, low noise, long service, lightweight, reliable operation and easy maintenance.

2. Application:

Series EZ slurry pumps are widely used in the mining, coal washery, power plant, metallurgy, petrochemical, building material, dredging and other industrial departments, etc. It is used in the various working sites including hydrocyclone feeding pump, magnetic separator feeding pump, underflow slurry pump (thickener underflow pump, filter separator underflow pump), flotation feeding pump, vibrating sieve feeding pump, shaking grading pressure pump, concentrate pump, and tailing pump.

3. Model Explanation:

300EZ-A70

300: Discharge diameter (mm)

E: Excellence brand

Z: Slurry pump

A: Number of vanes of impeller (A: 5 B: 4 C: 3 F: 7 G: 8)

70: Impeller diameter (cm)

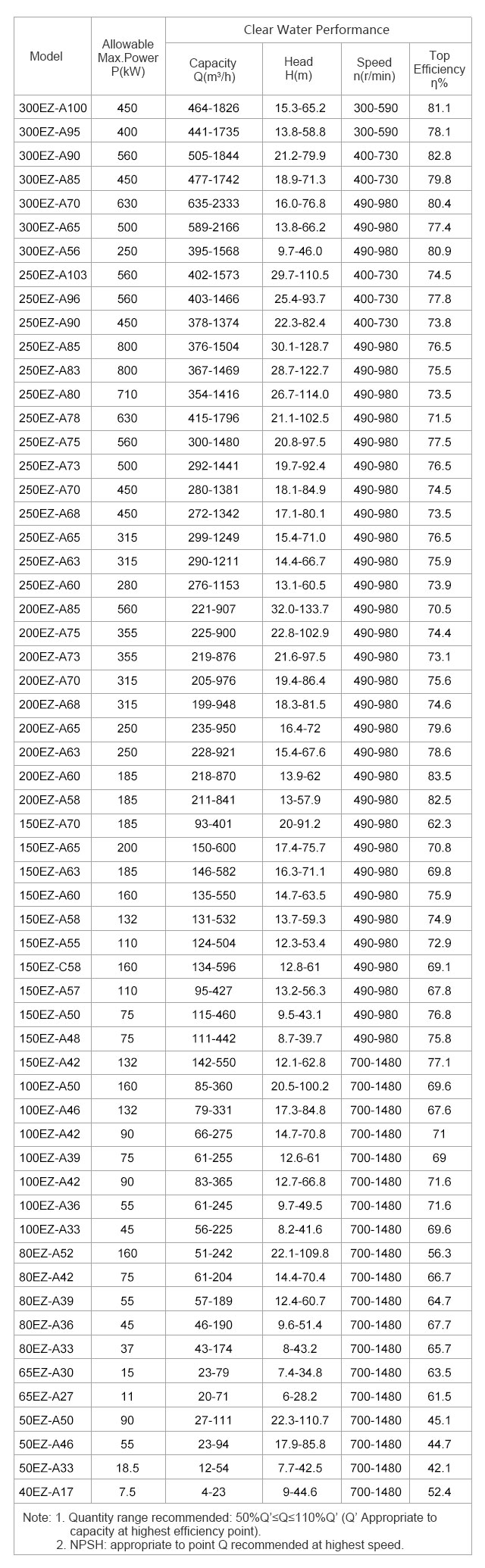

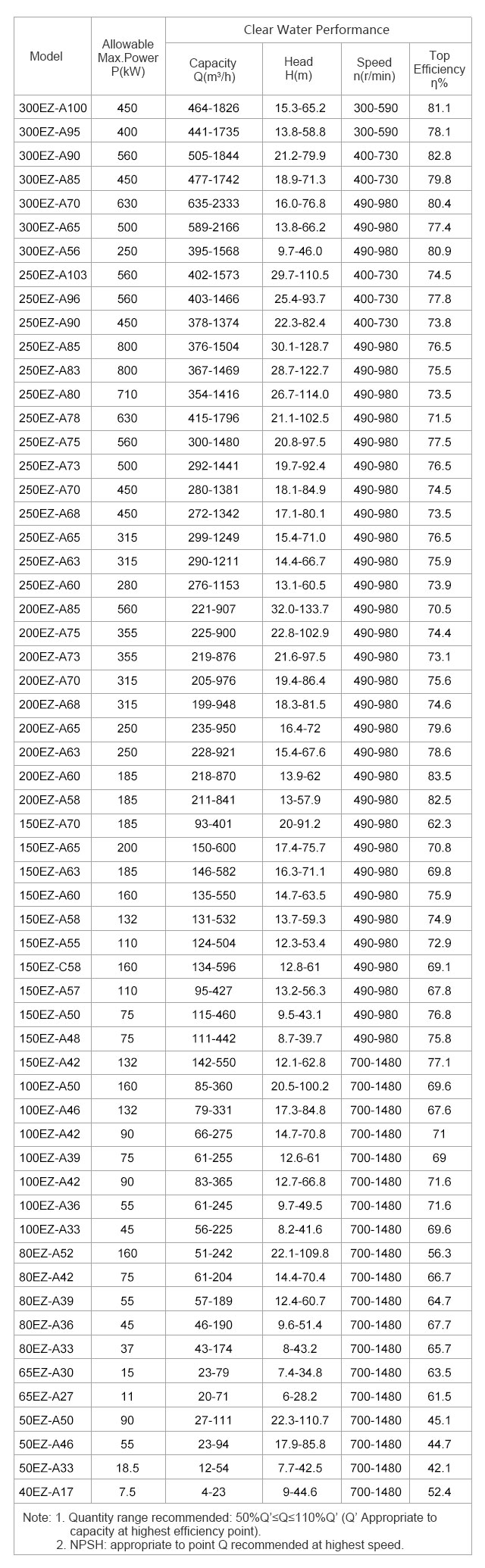

4. Performance Chart:

4. Performance Chart:

Related Keywords

Related Keywords