Horizontal Slurry Pump (ELM-150E)

- Payment Type:

- L/C, T/T, D/P

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T, D/P |

Product Description

Product Description

Horizontal Slurry Pump (ELM-150E)

1. Introduction:

Series ELM pumps are also called light slurry pumps. Compared with heavy duty slurry pumps like EHM and EGM pumps, ELM pumps are of small volume, light weight and high speed, which are suitable to transport tiny particles, low concentration or corrosive slurries. The concentration of the slurries is not over 30% usually.

2. Structure:

The frame plates of ELM Series Centrifugal slurry pump have changeable, wear-resistant metal liners or rubber liners upon request and the impellers are made of wear-resistant metal or rubber. And the discharge branch can be oriented to any of the eight different positions for installation and application upon request. The shaft seal is adopted both gland seal and centrifugal seal.

3. Application:

Series ELM slurry pumps are widely used in the mining, coal washery, power plant, metallurgy, petrochemical, building material, dredging and other industrial departments, etc. It is used in the various working sites including hydrocyclone feeding pump, magnetic separator feeding pump, underflow slurry pump (thickener underflow pump, filter separator underflow pump), flotation feeding pump, vibrating sieve feeding pump, shaking grading pressure pump, concentrate pump, and tailing pump.

4. Model Explanation: ELM-150E

1. Introduction:

Series ELM pumps are also called light slurry pumps. Compared with heavy duty slurry pumps like EHM and EGM pumps, ELM pumps are of small volume, light weight and high speed, which are suitable to transport tiny particles, low concentration or corrosive slurries. The concentration of the slurries is not over 30% usually.

2. Structure:

The frame plates of ELM Series Centrifugal slurry pump have changeable, wear-resistant metal liners or rubber liners upon request and the impellers are made of wear-resistant metal or rubber. And the discharge branch can be oriented to any of the eight different positions for installation and application upon request. The shaft seal is adopted both gland seal and centrifugal seal.

3. Application:

Series ELM slurry pumps are widely used in the mining, coal washery, power plant, metallurgy, petrochemical, building material, dredging and other industrial departments, etc. It is used in the various working sites including hydrocyclone feeding pump, magnetic separator feeding pump, underflow slurry pump (thickener underflow pump, filter separator underflow pump), flotation feeding pump, vibrating sieve feeding pump, shaking grading pressure pump, concentrate pump, and tailing pump.

4. Model Explanation: ELM-150E

E: Excellence brand

L: light duty

M: Metal lined

150: Discharge diameter (mm)

E: Frame type with maximum power

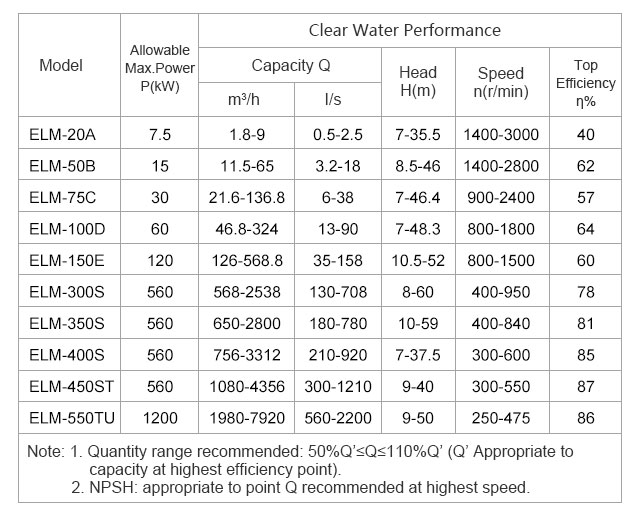

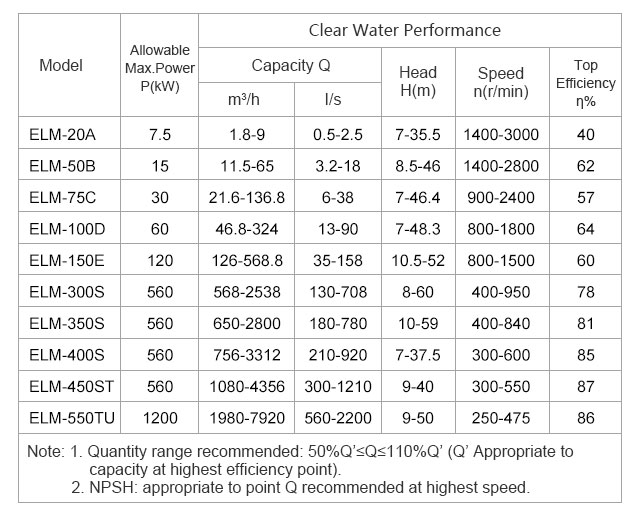

5. Parameters and Selection:

5. Parameters and Selection:

Related Keywords

Related Keywords