Horizontal High Efficiency Corrosion Resistant Slurry Pump

- Payment Type:

- T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shijiazhuang, China |

|---|---|

| Payment Type: | T/T |

Product Description

Product Description

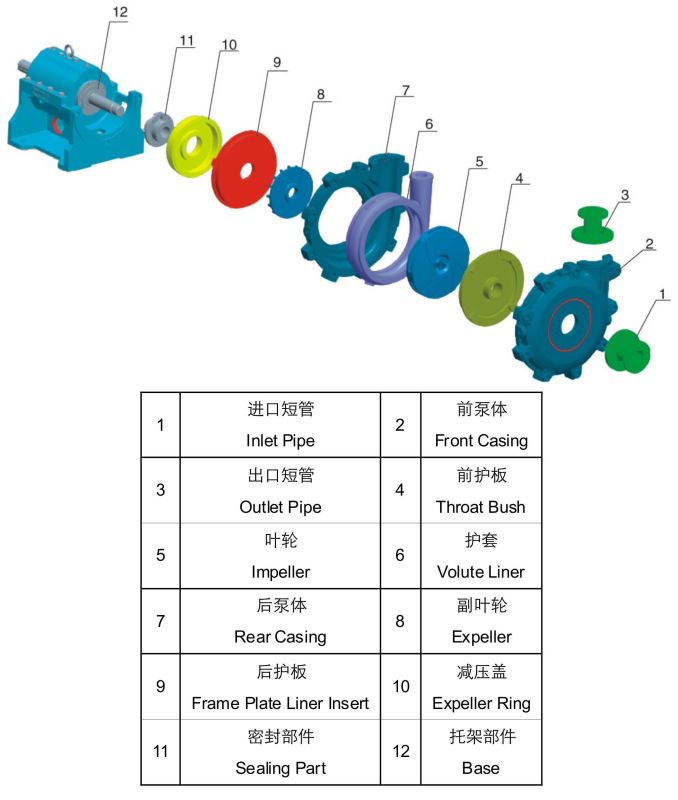

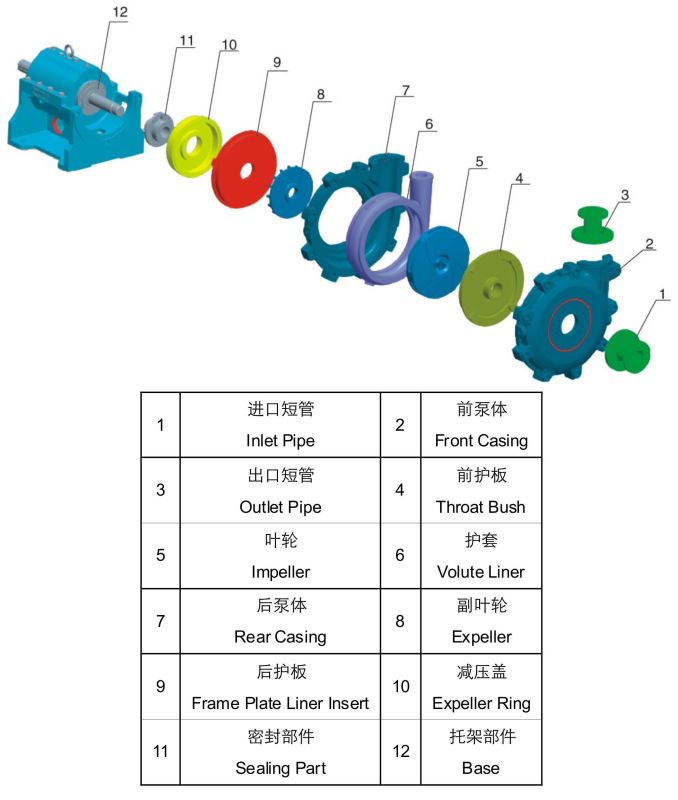

PUMP DESCRIPTION

HHE series is horizontal, cantilever, double casing, single-stage and single-suction centrifugal high head slurry pump. By introducing overseas advanced hydraulic model and internationally advanced solid-liquid two phase flow theory, our company newly designed this series of anti-abrasion and corrosion resistant slurry pump based on the principle of minimum hydraulic loss and abrasion. The fact that geometry of pump wet parts come in line with flowing state of pumped medium contributes to the reduction of local and whole course hydraulic loss due to vortex and flow impact. Consequently, the abrasion of wet parts can be mitigated. The pump series have following benefits: complete range of specifications and performance, novel structure, high efficiency and energy conservation, low vibration, reliable operation, long service life, easy installation and maintenance etc.

Design, manufacture and quality of this series conform to Standard JB/T8096 Centrifugal slurry pumps.

SPECIFICATIONS

Q: 4 → 3000m3/h (Design Point)

H: 6 → 133.7m (Design Point)

P: 7.5 → 800kw

η: 22 → 83%

n: 450 → 2980 r/min

Outlet Dia: 25 → 350mm

Working Temperature: ≤105oC

Max Weight Concentration of Allowable Transferred Solid-liquid Mixture:

Mortar (Slurry) and Coal Slurry ≤45%,

Pulp and Dense Medium ≤60%.

Normal through Size: 56% allowable intermittent through max size

Series: Two stages and multistage series connection need to confirm with technical department if more than two stages.

APPLICATIONS

This series widely apply to mines, metallurgy, power, coal, chemical engineering, building materials and flue gas desulphurization peripheral system etc., and are used for delivering slurry with abrasive particles or corrosive slurry.

HHE series is horizontal, cantilever, double casing, single-stage and single-suction centrifugal high head slurry pump. By introducing overseas advanced hydraulic model and internationally advanced solid-liquid two phase flow theory, our company newly designed this series of anti-abrasion and corrosion resistant slurry pump based on the principle of minimum hydraulic loss and abrasion. The fact that geometry of pump wet parts come in line with flowing state of pumped medium contributes to the reduction of local and whole course hydraulic loss due to vortex and flow impact. Consequently, the abrasion of wet parts can be mitigated. The pump series have following benefits: complete range of specifications and performance, novel structure, high efficiency and energy conservation, low vibration, reliable operation, long service life, easy installation and maintenance etc.

Design, manufacture and quality of this series conform to Standard JB/T8096 Centrifugal slurry pumps.

SPECIFICATIONS

Q: 4 → 3000m3/h (Design Point)

H: 6 → 133.7m (Design Point)

P: 7.5 → 800kw

η: 22 → 83%

n: 450 → 2980 r/min

Outlet Dia: 25 → 350mm

Working Temperature: ≤105oC

Max Weight Concentration of Allowable Transferred Solid-liquid Mixture:

Mortar (Slurry) and Coal Slurry ≤45%,

Pulp and Dense Medium ≤60%.

Normal through Size: 56% allowable intermittent through max size

Series: Two stages and multistage series connection need to confirm with technical department if more than two stages.

APPLICATIONS

This series widely apply to mines, metallurgy, power, coal, chemical engineering, building materials and flue gas desulphurization peripheral system etc., and are used for delivering slurry with abrasive particles or corrosive slurry.

Related Keywords

Related Keywords