Energy Saving Petrol Chemical Slurry Pump

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- TIanjin, Shanghai, Huoerguosi Port

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shijiazhuang |

|---|---|

| Productivity: | 300sets/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air |

| Port: | TIanjin,Shanghai,Huoerguosi Port |

Product Description

Product Description

Product Description

Slurry pump has features as follows: smooth operation; energy saving; low noise; high flow and head; low production cost; high efficiency; easy maintenance; long service life.

A complete range of build specifications

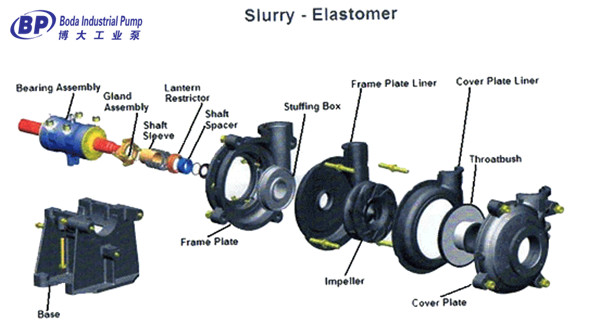

- Rubber lined with rubber impeller

- Rubber lined with metal impeller

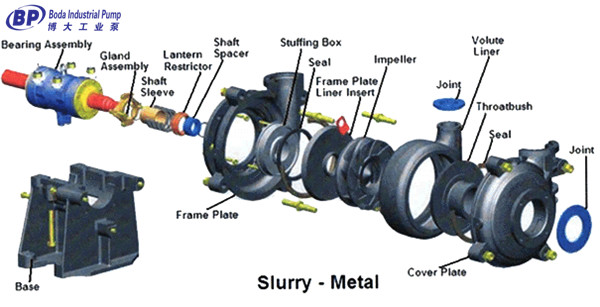

- All metal lined using white iron chrome alloys

- Urethane lined with optional urethane impeller for special applications

Features

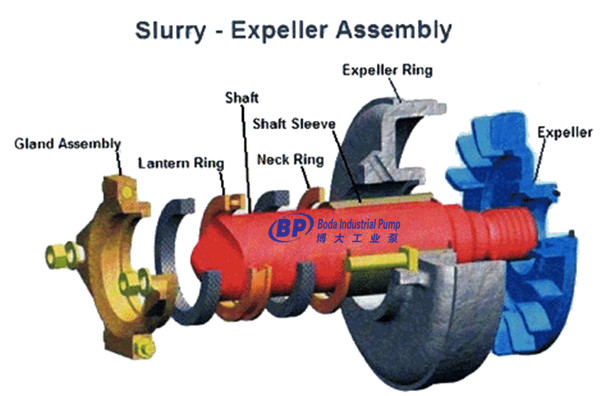

1. Double casings design centrifugal slurry pump, wide passage for solids;

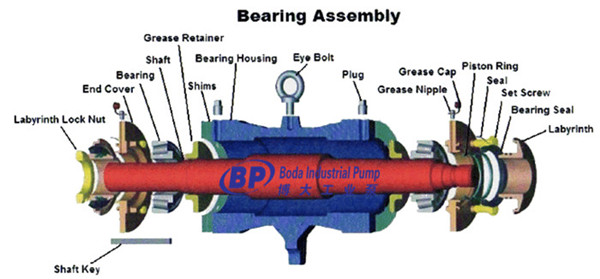

2. Bearing assembly & frame: Both standard & high capacity type available. A large diameter shaft with a short overhang minimizes deflection and vibration. Heavy duty roller bearing are housed in a removable bearing cartridge. Pump body is fastened with the frame by minimum bolts. Impeller adjustment is provided in a convenient position below the bearing assembly.

3. Impeller & liner material: high chrome white iron, etc.

4. Impeller type: open or closed

5. Interchangeable wet parts material: High chrome alloy metal: PH: 5-12

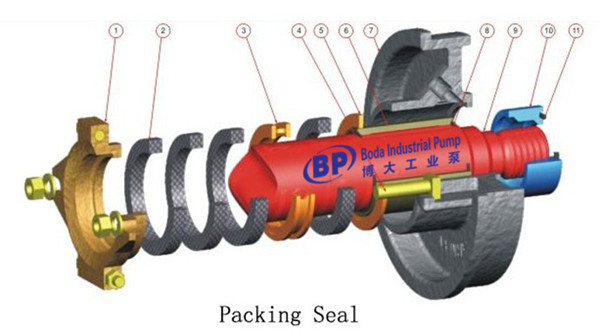

6. Shaft seal: Packing seal, centrifugal seal, mechanical seal;

7. Discharge branch: 8 positions in each 45°;

8. Driving type: V-belt, flexible coupling, gearbox, hydraulic coupler, etc..

Horizontal Abrasion & Corrosion Resistant Slurry Pump Performance Table:

|

Type

|

Allowable Mating Max.Power(kw)

|

Clear Water Performance

|

Impeller

|

||||||

|

Capacity Q

|

Head

H

(m) |

Speed

n

(r/min) |

Max EFF η(%)

|

NPSH)

(m) |

No of Vanes

|

Impel Dia(mm)

|

|||

|

(m3/h)

|

(L/S)

|

||||||||

|

1.5/1B-BH

|

15

|

12.6-28.8

|

3.5-8

|

6-68

|

1200-3800

|

40

|

2-4

|

5

|

152

|

|

2/1.5B-BH

|

15

|

32.4-72

|

9-20

|

6-58

|

1200-3200

|

45

|

3.5-8

|

5

|

184

|

|

3/2C-BH

|

30

|

39.6-86.4

|

11-24

|

12-64

|

1300-2700

|

55

|

4-6

|

5

|

214

|

|

4/3C-BH

|

30

|

86.4-198

|

24-55

|

9-52

|

1000-2200

|

71

|

4-6

|

5

|

245

|

|

4/3D-BH

|

60

|

||||||||

|

6/4D-BH

|

60

|

162-360

|

45-100

|

12-56

|

800-1550

|

65

|

5-8

|

5

|

365

|

|

6/4E-BH

|

120

|

||||||||

|

6/4D-BH

|

60

|

180-396

|

50-110

|

7-61

|

600-1600

|

55

|

3-8

|

4

|

372

|

|

6/4E-BH

|

120

|

||||||||

|

8/6E-BH

|

120

|

360-828

|

100-230

|

10-61

|

500-1140

|

72

|

2-9

|

5

|

510

|

|

8/6R-BH

|

300

|

||||||||

|

8/6E-BH

|

120

|

360-828

|

100-230

|

7-52

|

400-1000

|

70

|

2.5-6

|

4

|

536

|

|

8/6R-BH

|

300

|

360-828

|

100-230

|

7-52

|

400-1000

|

70

|

2.5-6

|

4

|

536

|

|

10/8ST-BH

|

560

|

612-1368

|

170-380

|

11-61

|

400-850

|

71

|

4-10

|

5

|

686

|

|

12/10ST-BH

|

560

|

936-1980

|

260-550

|

7-68

|

300-800

|

82

|

6

|

5

|

762

|

|

14/12ST-BH

|

560

|

1260-2772

|

350-770

|

13-63

|

300-600

|

77

|

3-10

|

5

|

965

|

|

16/14ST-BH

|

560

|

1368-3060

|

380-850

|

11-63

|

250-550

|

79

|

4-10

|

5

|

1067

|

|

16/14TU-BH

|

1200

|

||||||||

|

10/8E-BM

|

120

|

540-1440

|

150-400

|

14-60

|

600-1100

|

73

|

4-10

|

5

|

549

|

* Dimensionally Interchangeable

Horizontal Abrasion & Corrosion Resistant Slurry Pump Structure:

Horizontal Abrasion & Corrosion Resistant Slurry Pump Application:

Related Keywords

Related Keywords