Abrasion Resistant Centrifugal Sand and Gravel Slurry Pumps

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Productivity: | 300sets/month |

| Supply Ability: | 500 sets/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Qingdao,Shanghai |

Centrifugal Expeller Seal Slurry Pump:

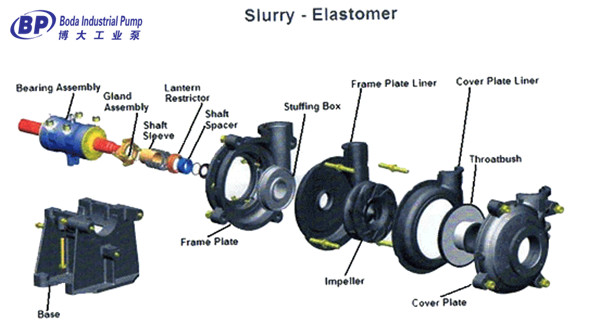

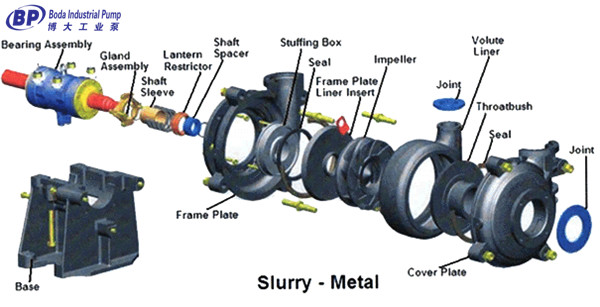

Abrasion Resistant Centrifugal Sand and Gravel Slurry Pumps

1.Paramters

Size range (outlet):----- 1'' to 18'' (25 mm to 450 mm)

Capacity:-------------- up to 22,000 gpm ( 5,000 m3/hr )

Head: -----------------up to 240 ft (73 m )

Pressure: --------------up to 300 psi (2,020 kPa)

BH(R) hard metal / rubber heavy duty slurry pumps are designed for the most difficult pumping applications for highly abrasive, high density or erosive slurries.

Extra thick sections at wear point and perfect impeller structure ensures satisfactory performance with long life, and needs minimum maintenance requirements.

Rubber lined pump expand applications to chemical products handing, several different rubber options are available to meet different application needs.

Especially fit in aggressive applications like mill discharge, tailing transportation.

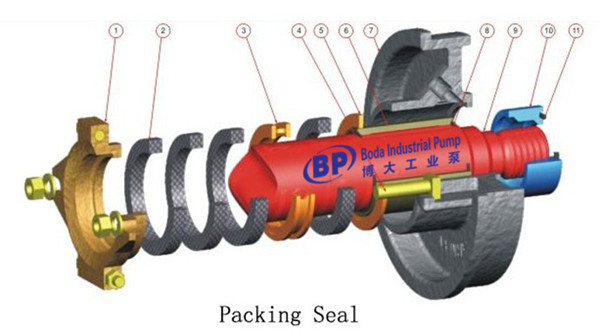

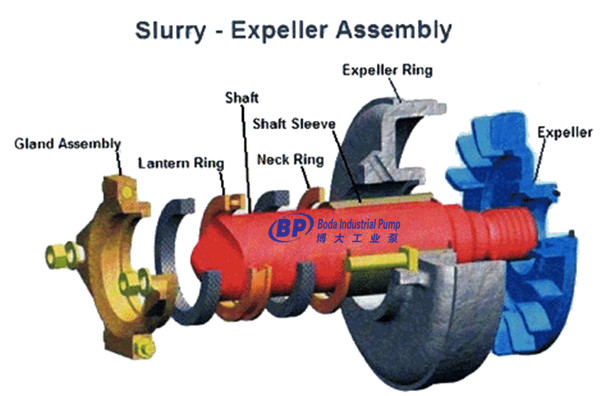

Shaft seal could use the packing seal, expeller seal and mechanical seal.

Drive types: direct coupling drive(DC), V belt drive(CR, CV, ZV, CL), etc.

Material:

|

Rubber Pump |

Metal Pump |

||||

|

No. |

Part Description |

Material Specification |

No. |

Part Description |

Material Specification |

|

1 |

Base |

Cast Iron |

1 |

Base |

Cast Iron |

|

2 |

Shaft |

4140 High Tensile Steel* |

2 |

Shaft 4140 |

High Tensile Steel* |

|

3 |

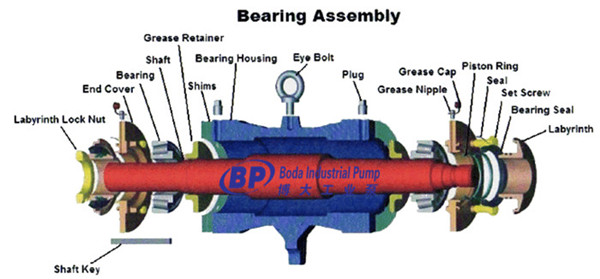

Bearing Assembly |

Timken (Cast Iron Body) |

3 |

Bearing Assembly |

Timken (Cast Iron Body) |

|

4 |

Shaft Sleeve |

420 Stainless Steel |

4 |

Shaft Sleeve |

420 Stainless Steel |

|

5 |

Pump Casing |

Cast Iron |

5 |

Pump Casing |

Cast Iron |

|

6 |

Frame Plate |

Liner Insert Rubber |

6 |

Frame Plate |

Liner 27% Chrome White Iron |

|

7 |

Cover Plate |

Liner Rubber |

7 |

Volute Liner |

27% Chrome White Iron |

|

8 |

Impeller |

Rubber Coated High Tensile Steel |

8 |

Impeller 27% |

Chrome White Iron |

|

9 |

Throat Bush |

Rubber |

9 |

Throat Bush |

27% Chrome White Iron |

|

10 |

Cover Plate |

Cast Iron |

10 |

Joint Rings |

Rubber |

|

11 |

Stuffing Box |

Cast Iron |

11 |

Cover Plate |

Cast Iron |

|

12 |

Expeller |

27% Chrome White Iron |

12 |

Stuffing Box |

Cast Iron |

|

13 |

Expeller |

Ring Natural Rubber |

13 |

Expeller |

27% Chrome White Iron |

|

14 |

Bolts |

Zinc Plated Steel |

14 |

Expeller Ring |

Natural Rubber |

|

15 |

O-rings |

Nitrile Rubber |

15 |

Bolts |

Zinc Plated Steel |

|

16 |

Seals |

Rubber |

16 |

O-rings |

Nitrile Rubber |

|

17 |

Seals |

Rubber |

|||

Centrifugal Expeller Seal Slurry Pump Performance Table:

|

Type

|

Allowable Mating Max.Power(kw)

|

Clear Water Performance

|

Impeller

|

||||||

|

Capacity Q

|

Head

H

(m) |

Speed

n

(r/min) |

Max EFF η(%)

|

NPSH)

(m) |

No of Vanes

|

Impel Dia(mm)

|

|||

|

(m3/h)

|

(L/S)

|

||||||||

|

1.5/1B-BH

|

15

|

12.6-28.8

|

3.5-8

|

6-68

|

1200-3800

|

40

|

2-4

|

5

|

152

|

|

2/1.5B-BH

|

15

|

32.4-72

|

9-20

|

6-58

|

1200-3200

|

45

|

3.5-8

|

5

|

184

|

|

3/2C-BH

|

30

|

39.6-86.4

|

11-24

|

12-64

|

1300-2700

|

55

|

4-6

|

5

|

214

|

|

4/3C-BH

|

30

|

86.4-198

|

24-55

|

9-52

|

1000-2200

|

71

|

4-6

|

5

|

245

|

|

4/3D-BH

|

60

|

||||||||

|

6/4D-BH

|

60

|

162-360

|

45-100

|

12-56

|

800-1550

|

65

|

5-8

|

5

|

365

|

|

6/4E-BH

|

120

|

||||||||

|

6/4D-BH

|

60

|

180-396

|

50-110

|

7-61

|

600-1600

|

55

|

3-8

|

4

|

372

|

|

6/4E-BH

|

120

|

||||||||

|

8/6E-BH

|

120

|

360-828

|

100-230

|

10-61

|

500-1140

|

72

|

2-9

|

5

|

510

|

|

8/6R-BH

|

300

|

||||||||

|

8/6E-BH

|

120

|

360-828

|

100-230

|

7-52

|

400-1000

|

70

|

2.5-6

|

4

|

536

|

|

8/6R-BH

|

300

|

360-828

|

100-230

|

7-52

|

400-1000

|

70

|

2.5-6

|

4

|

536

|

|

10/8ST-BH

|

560

|

612-1368

|

170-380

|

11-61

|

400-850

|

71

|

4-10

|

5

|

686

|

|

12/10ST-BH

|

560

|

936-1980

|

260-550

|

7-68

|

300-800

|

82

|

6

|

5

|

762

|

|

14/12ST-BH

|

560

|

1260-2772

|

350-770

|

13-63

|

300-600

|

77

|

3-10

|

5

|

965

|

|

16/14ST-BH

|

560

|

1368-3060

|

380-850

|

11-63

|

250-550

|

79

|

4-10

|

5

|

1067

|

|

16/14TU-BH

|

1200

|

||||||||

|

10/8E-BM

|

120

|

540-1440

|

150-400

|

14-60

|

600-1100

|

73

|

4-10

|

5

|

549

|

* Dimensionally Interchangeable

Horizontal Abrasion & Corrosion Resistant Slurry Pump Structure:

Horizontal Abrasion & Corrosion Resistant Slurry Pump Application:

Related Keywords