FGD Slurry Pump for Desulfurizing Processing TL(R)

- Payment Type:

- L/C, T/T, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500 |

| Supply Ability: | 500 |

| Payment Type: | L/C,T/T,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin |

D:350-1000mm

Q:1500-14000 m3/h

H:12-32m

Product Description:

1) The pump restricting parts adopt the advanced flow simulation technology to guarantee the reliable

pump design and the high operating efficiency.

2) The anticorrosion & antiwear metal and rubber materials which are specifically developed for FGD

pumps have been proved by the practice that, they can ensure the longlife pump operation.

Through adjusting the bearing components to change the impeller position in the pump chamber

alltime highefficient operation of the pump can be achieved. The pump is characterized by the back

knock-down structure which is simple and advanced.

3) It is easy to maintain and repair and it is on need dismantling inlet and outlet water pipes.

The containerized mechanical seal specially used for the desulphurization process is adopted and

its operation is reliable.

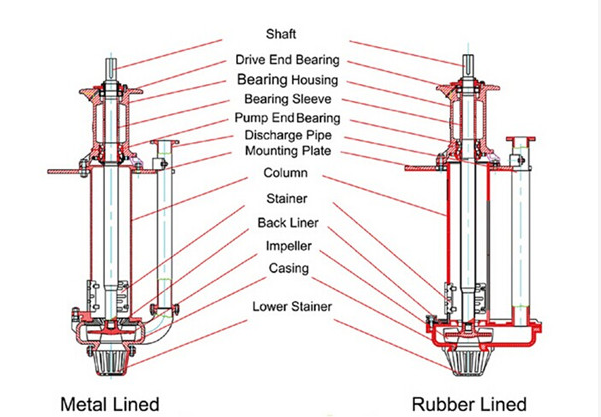

Material Selection:

we have developed a new kind of specialized material which possesses the duplex stainless steel's anti-corrosive property and the high chrome white iron's anti-abrasive property in FGD process.

In the rubber pump casing, impeller, suction cover/cover plate are all made of specialized anti-wear and anti-corrosive material: the material of front liner, back liner and back liner insert are natural rubber having excellent anti-corrosive property.

In metal pump casing, impeller, volute liner, suction plate and back plate are all made of specialized anti-wear and anti-corrosive material, the suction cover are made of ductile iron with rubber.

Applications:

They are mainly used to handle slurry with smoke in absorption tower of electric power station,

that is thermal power plant FGD (Flue Gas Desulfurization) Project.

|

Type |

Capacity (m3/h) |

Head(m) |

Speed(r/min) |

Maximum efficiency η(%) |

NPSH (m) |

Outlet diameter (mm) |

Inlet diameter (mm) |

|

350X-TL(R) |

1600 |

25 |

960 |

82 |

4.5 |

350 |

400 |

|

400X-TL(R) |

2500 |

25 |

725 |

83 |

5.0 |

400 |

450 |

|

500X-TL(R) |

3750 |

25 |

725 |

85 |

5.0 |

500 |

500 |

|

600X-TL(R) |

6300 |

25.5 |

620 |

88 |

5.5 |

600 |

700 |

|

700X-TL(R) |

6840 |

26 |

485 |

87 |

6.0 |

700 |

800 |

|

800X-TL(R) |

9360 |

31 |

485 |

90 |

7.0 |

800 |

900 |

|

900X-TL(R) |

15000 |

30 |

485 |

90 |

8.5 |

900 |

1000 |

|

1000X-TL |

10440 |

15 |

485 |

89 |

7.0 |

1000 |

1200 |

Related Keywords