Industrial flue gas dedusting system manufacturing

- Delivery Time:

- 4 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

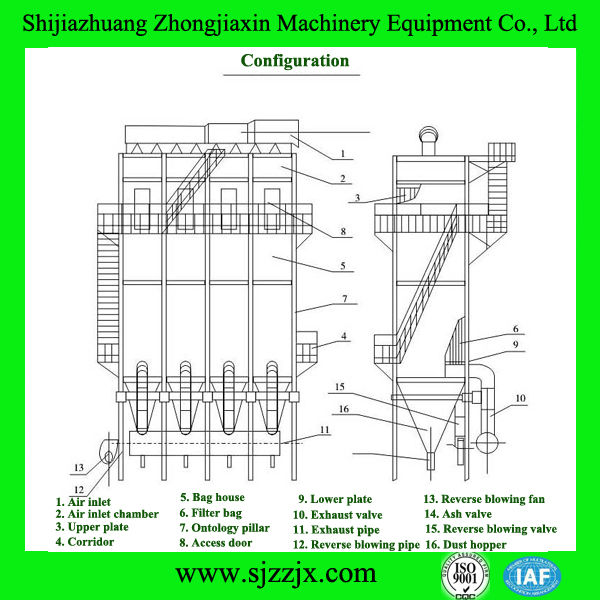

Detailed parameters of Baghouse Bag Filter Dust Collection System:We design Baghouse Bag Filter with different air capacity as specific requriement.

Detailed parameters of Baghouse Bag Filter Dust Collection System:We design Baghouse Bag Filter with different air capacity as specific requriement. Model parameters | Air Capacity(m³/h) | Gross filtration area(m³) | Net filtration area(m³) | Chamber quantity | Filter bag | |

quantity | specification | |||||

PPCS32-3 | 6900 | 93 | 62 | 3 | 96 | 130×2450mm |

PPCS32-4 | 8930 | 124 | 93 | 4 | 128 | |

PPCS32-5 | 11160 | 155 | 124 | 5 | 160 | |

PPCS32-6 | 13390 | 186 | 155 | 5 | 192 | |

PPCS64-4 | 17800 | 248 | 186 | 4 | 256 | |

PPCS64-5 | 22300 | 310 | 248 | 5 | 320 | |

PPCS64-6 | 26700 | 372 | 310 | 6 | 384 | |

PPCS64-7 | 31200 | 434 | 372 | 7 | 448 | |

PPCS64-8 | 35700 | 496 | 434 | 8 | 512 | |

PPCS96-4 | 26800 | 372 | 279 | 4 | 384 | |

PPCS96-5 | 33400 | 465 | 372 | 5 | 480 | |

PPCS96-6 | 40100 | 557 | 465 | 56 | 576 | |

PPCS96-7 | 46800 | 650 | 557 | 7 | 672 | |

PPCS96-8 | 53510 | 744 | 650 | 8 | 768 | |

PPCS96-9 | 60100 | 836 | 744 | 9 | 864 | |

PPCS96-2×5 | 66900 | 929 | 836 | 10 | 960 | |

PPCS96-2×6 | 80700 | 1121 | 1028 | 12 | 1152 | |

PPCS96-2×7 | 94100 | 1308 | 1251 | 14 | 1344 | |

PPCS96-2×8 | 107600 | 1494 | 1401 | 16 | 1536 | |

PPCS96-2×9 | 121000 | 1681 | 1588 | 18 | 1728 | |

PPCS96-2×10 | 134500 | 1868 | 1775 | 20 | 1920 | |

PPCS128-6 | 67300 | 935 | 779 | 6 | 768 | 130×3060mm |

PPCS128-9 | 100900 | 1402 | 1246 | 9 | 1152 | |

PPCS128-10 | 112100 | 1558 | 1402 | 10 | 1280 | |

PPCA128-2×6 | 134600 | 1869 | 1713 | 12 | 1536 | |

PPCA128-2×7 | 157000 | 2181 | 2025 | 14 | 1792 | |

PPCA128-2×8 | 179400 | 2492 | 2336 | 16 | 2084 | |

PPCA128-2×9 | 201900 | 2804 | 2648 | 18 | 2304 | |

PPCA128-2×10 | 224300 | 3115 | 2959 | 20 | 2560 | |

PPCA128-2×11 | 247600 | 3427 | 3271 | 22 | 2816 | |

PPCA128-2×12 | 269100 | 3738 | 3582 | 24 | 3072 | |

PPCA128-2×13 | 294600 | 4050 | 3894 | 26 | 3328 | |

PPCA128-2×14 | 314000 | 4361 | 4205 | 28 | 3584 | |

\

\  Related pics of bag filter:

Related pics of bag filter:

Our Services and Quality Guarantee We have strong technology term and installation personnel. Consult → design → process planning → production → quality control → delivery → After-sales tracking. 12months Quality warranty period (after put into operation formally). During the warranty period, if occurred due to the goods themselves cause malfunction or damage, the Company will guide maintenance or replacement of the corresponding parts without pay, if need to go site, buyer charge the transport fee and accommodation of engineer. Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price. Company Information We are the manufacturer. Main Products:

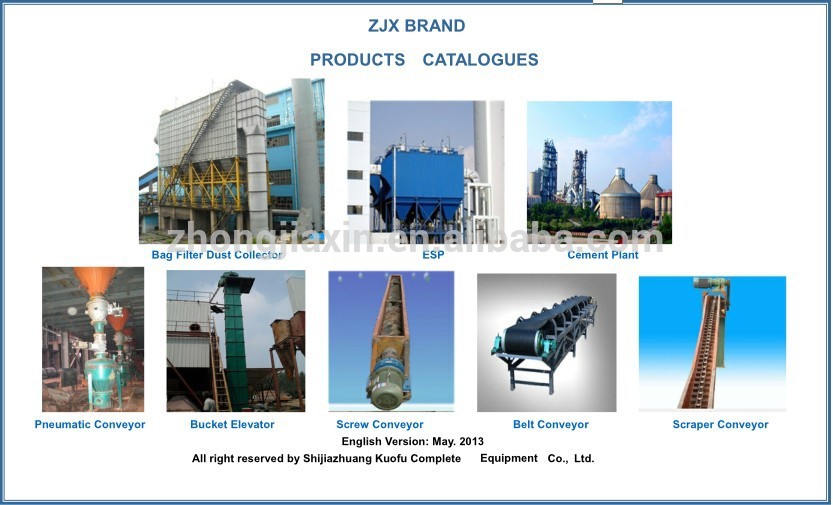

Our Services and Quality Guarantee We have strong technology term and installation personnel. Consult → design → process planning → production → quality control → delivery → After-sales tracking. 12months Quality warranty period (after put into operation formally). During the warranty period, if occurred due to the goods themselves cause malfunction or damage, the Company will guide maintenance or replacement of the corresponding parts without pay, if need to go site, buyer charge the transport fee and accommodation of engineer. Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price. Company Information We are the manufacturer. Main Products: 1. Conveying Equipment__ Bucket Elevator, Scraper Conveyor, Screw Conveyor, Belt Conveyor, Pneumatic conveying system

2. Dust-cleaning Equipment __Bag Filter Dust Collector,ESP Dust Collector, Cyclone Dust Collector

3. Patented Product__ Dust Humidifier.

4. Complete Cement production line equipment

Certification:

Quality Certification of ISO9001:2008

Patent of Dust Humidifier

Packaging & Shipping We test dust collector before it is packaged and transported: Packaging and transporting: we usually use composite material box or steel box to package the easy damage parts, we can also do as the customer's request.

Packaging & Shipping We test dust collector before it is packaged and transported: Packaging and transporting: we usually use composite material box or steel box to package the easy damage parts, we can also do as the customer's request.  Customers' Guidance Please including the following items when send an inquiry, so we can give a fast answer. 1. What's the gas temperature at Bag Filter's inlet? 2. What's the medium will be filtered? In another word, where the gas come from? 3. What's the air capacity OR the filter area? Fast Feedback:

Customers' Guidance Please including the following items when send an inquiry, so we can give a fast answer. 1. What's the gas temperature at Bag Filter's inlet? 2. What's the medium will be filtered? In another word, where the gas come from? 3. What's the air capacity OR the filter area? Fast Feedback:

Related Keywords