Hot selling baghouse dust catcher system for cement plant

- Delivery Time:

- 60 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

Bag House FIlter Dust Collector Introduction: 1.PPC-Air box pulse bag filter dust collector collect the advantages from seperate chamber-backblowing dust extractor and pulse jet dust extractor. It has overcome the disadvantages that the seperate chamber-backblowing is lack of cleaning dust as well as jet cleaning and filtering are working at the same time. 2.It is widely used not only in purifying common dust air,but also used in filter heavy dust air that the dust concentration reach 1300g/m3 in stack gas. It is successfully to be the supporting recycling equipment of O-sepa separator,vertical mill products. 3.It has a high collection efficiency and a long time life span, the operating is reliable, these advantages making it become the ideal product to protect environment. 4.Air box pulse dust extractor was divided into several box area, per box area has 32/64/96/128 pieces of filter bag. It is a machine that have a small size, light weight, compact structure, good shell strength and there is no need to unload Ash Conveying Equipment, these make it take a low power and small amount of maintenance. with a low cost, it is widely used to deal with local dust source waste gas where the dust content less than 250g/Nm3 as well as air volume less than 30000m3/h, have a limit space to set.Furthermore, with this technique can reform Reverse Jet Flat Bag Dust Collector into Gas Box Pulse Bag Filter Dust Collector. Air Box Pulse Dust Collection Features: 1. Easy install 2. Simple structure 3. Cover a small area 4. Complete clear the dust 5. Little resistance during operation 6. Widely used in crushing, packing, top of your library, clinker cooler, and various types of mills and other dust collection system of a cement plant for the coal mill dust with anti-blasting measures. Bag House FIlter Dust Collector Specification:

Bag House FIlter Dust Collector Introduction: 1.PPC-Air box pulse bag filter dust collector collect the advantages from seperate chamber-backblowing dust extractor and pulse jet dust extractor. It has overcome the disadvantages that the seperate chamber-backblowing is lack of cleaning dust as well as jet cleaning and filtering are working at the same time. 2.It is widely used not only in purifying common dust air,but also used in filter heavy dust air that the dust concentration reach 1300g/m3 in stack gas. It is successfully to be the supporting recycling equipment of O-sepa separator,vertical mill products. 3.It has a high collection efficiency and a long time life span, the operating is reliable, these advantages making it become the ideal product to protect environment. 4.Air box pulse dust extractor was divided into several box area, per box area has 32/64/96/128 pieces of filter bag. It is a machine that have a small size, light weight, compact structure, good shell strength and there is no need to unload Ash Conveying Equipment, these make it take a low power and small amount of maintenance. with a low cost, it is widely used to deal with local dust source waste gas where the dust content less than 250g/Nm3 as well as air volume less than 30000m3/h, have a limit space to set.Furthermore, with this technique can reform Reverse Jet Flat Bag Dust Collector into Gas Box Pulse Bag Filter Dust Collector. Air Box Pulse Dust Collection Features: 1. Easy install 2. Simple structure 3. Cover a small area 4. Complete clear the dust 5. Little resistance during operation 6. Widely used in crushing, packing, top of your library, clinker cooler, and various types of mills and other dust collection system of a cement plant for the coal mill dust with anti-blasting measures. Bag House FIlter Dust Collector Specification: Model parameters | Air Capacity(m³/h) | Gross filtration area(m³) | Net filtration area(m³) | Chamber quantity | Filter bag | Air consumption(m³/min) | Impeller-type feeder | Tube screw conveyor | |

quantity | specification | ||||||||

PPCS32-3 | 6900 | 93 | 62 | 3 | 96 | 130×2450 mm | 0.27 | 300×300(mm) motor power 1.1KW |

|

PPCS32-4 | 8930 | 124 | 93 | 4 | 128 | 0.37 |

| ||

PPCS32-5 | 11160 | 155 | 124 | 5 | 160 | 0.46 |

| ||

PPCS32-6 | 13390 | 186 | 155 | 5 | 192 | 0.55 |

| ||

PPCS64-4 | 17800 | 248 | 186 | 4 | 256 | 1.2 | 300mm 30m³/h motor power 2.2KW | ||

PPCS64-5 | 22300 | 310 | 248 | 5 | 320 | 1.5 | |||

PPCS64-6 | 26700 | 372 | 310 | 6 | 384 | 1.8 | |||

PPCS64-7 | 31200 | 434 | 372 | 7 | 448 | 2.1 | |||

PPCS64-8 | 35700 | 496 | 434 | 8 | 512 | 2.4 | |||

PPCS96-4 | 26800 | 372 | 279 | 4 | 384 | 1.2 | 400×400(mm) motor power 1.5KW | 400mm38 (m³/h ) motor power 5.5KW | |

PPCS96-5 | 33400 | 465 | 372 | 5 | 480 | 1.5 | |||

PPCS96-6 | 40100 | 557 | 465 | 56 | 576 | 1.8 | |||

PPCS96-7 | 46800 | 650 | 557 | 7 | 672 | 2.1 | |||

PPCS96-8 | 53510 | 744 | 650 | 8 | 768 | 2.4 | |||

PPCS96-9 | 60100 | 836 | 744 | 9 | 864 | 2.7 | |||

PPCS96-2×5 | 66900 | 929 | 836 | 10 | 960 | 3.0 | 2 sets 350×350(mm) motor power 2×1.5KW | 2 sets 300mm 2X21m³/h motor power 2.2KW | |

PPCS96-2×6 | 80700 | 1121 | 1028 | 12 | 1152 | 3.4 | |||

PPCS96-2×7 | 94100 | 1308 | 1251 | 14 | 1344 | 4.2 | |||

PPCS96-2×8 | 107600 | 1494 | 1401 | 16 | 1536 | 4.8 | |||

PPCS96-2×9 | 121000 | 1681 | 1588 | 18 | 1728 | 5.4 | |||

PPCS96-2×10 | 134500 | 1868 | 1775 | 20 | 1920 | 6.0 | |||

Our Services We have strong technology term and installation personnel. Consult → design → process planning → production → quality control → delivery → After-sales tracking. 12months Quality warranty period (after put into operation formally). During the warranty period, if occurred due to the goods themselves cause malfunction or damage, the Company will guide maintenance or replacement of the corresponding parts without pay, if need to go site, buyer charge the transport fee and accommodation of engineer. Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price.

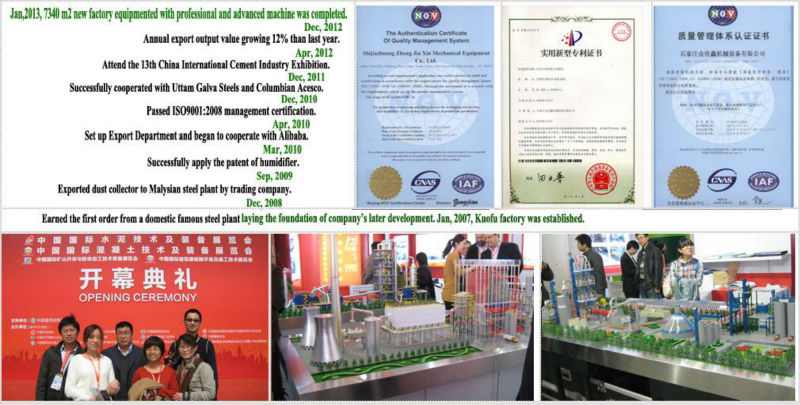

Our Services We have strong technology term and installation personnel. Consult → design → process planning → production → quality control → delivery → After-sales tracking. 12months Quality warranty period (after put into operation formally). During the warranty period, if occurred due to the goods themselves cause malfunction or damage, the Company will guide maintenance or replacement of the corresponding parts without pay, if need to go site, buyer charge the transport fee and accommodation of engineer. Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price.  Company Information Shijiazhuang Kuofu Complete Equipment Co., Ltd Established in 2002 year, pass ISO9001:2008. A manufacturer of Dust collector, Bucket elevator, Conveying equipments, cement production line and related products. Industry Dust collector- Bag Filter, ESP, Cyclone Dust Collector Bucket Elevator Scraper Conveyor , Screw Conveyor, Pneumatic Conveyor Dust Humidifying Machine Filter Bag Pulse Valve Advantage of company: 1. Design: have our own Engineer term, each machine is designed as customer’s specific requirement, the performace is higher 20~40% than other factory with same cost. 2. Quality: Test machines and have commercial inspection before shipping, maintanence is lower 20%-30% than the same industry. 3. After-service: provide technical guidance freely during machine service life.

Company Information Shijiazhuang Kuofu Complete Equipment Co., Ltd Established in 2002 year, pass ISO9001:2008. A manufacturer of Dust collector, Bucket elevator, Conveying equipments, cement production line and related products. Industry Dust collector- Bag Filter, ESP, Cyclone Dust Collector Bucket Elevator Scraper Conveyor , Screw Conveyor, Pneumatic Conveyor Dust Humidifying Machine Filter Bag Pulse Valve Advantage of company: 1. Design: have our own Engineer term, each machine is designed as customer’s specific requirement, the performace is higher 20~40% than other factory with same cost. 2. Quality: Test machines and have commercial inspection before shipping, maintanence is lower 20%-30% than the same industry. 3. After-service: provide technical guidance freely during machine service life.  FAQ Customer Guidance: 1. What kind of factory the dust collector will be installed in? 2. The medium will be filtered? 3. The temperature at dust collector's inlet? 4. The capacity? Because with these factors, we are able to give you a fast answer.

FAQ Customer Guidance: 1. What kind of factory the dust collector will be installed in? 2. The medium will be filtered? 3. The temperature at dust collector's inlet? 4. The capacity? Because with these factors, we are able to give you a fast answer.

Related Keywords