Roller chain Bucket elevator conveyor for bulk materials handling

- Delivery Time:

- 25 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Roller chain Bucket elevator conveyor for bulk materials handling Product Description Brief introduction of TH type bucket elevator : TH type bucket elevator is a ring chain bucket elevator use of hybrid or gravity discharge, digging loader. TH bucket elevator traction parts are made of high quality steel ring chain. Central case divided into single and dual channel two forms of machine hammer box Constant automatic tensioning. Sprocket rims interchangeable modular structure. Long service life and easy replacement rim. The lower part adopt the gravity automatic tensioning device, to maintain a constant tension, to prevent slippage or take off the chain, while the hopper stuck encountered phenomenon caused by accidental factors have a certain tolerance , can effectively protect the lower shaft parts. Main features of TH type bucket elevator: 1. Large transportation amount, the same bucket width TH type compared with HL type bucket elevators, throughput nearly increase doubled;

2. Using the assembled sprocket.This bucket elevator by wheel body, flange with high strength bolt composition .After the sprocket wheel wear to a certain degree, it can be unscrewed the bolt, changing a wheel rim, easy to change, and save material, reduce the maintenance costs;

3. The lower part using the heavy hammer lever tensioning device, automatic tension can be realized. After an installation does not need to adjust, and can keep constant tension, to ensure the normal operation of the machine, and avoid the skid or take off the chain;

4. Traction with high strength low alloy ring chain, after proper heat treatment, has the very high tensile strength and wear resistance, long service life.

Technical parameters for your reference :

Notes: Our TH Bucket elevator can be working in the environment where the temperature is around 150'C and its lifting height is no higher than 40m Application of TH type bucket elevator: It is adopt hybrid discharge or gravity discharge, dig loader for conveying bulk density of the material is not greater than 1.5t/m3 powdery , granular, small block of low- abrasive materials , the material temperature must not exceed 250 degrees.This machine is equipped with two types of hopper: zh (in a deep bucket) commonly used in conveying wet, bulk, and materials which difficult to throw, such as wet sand,foundry sand, fertilizer, alkali powder, etc.Sh type (deep bucket) commonly used in conveying dry, materials which easy to throw, such as cement, gravel, coal, etc.

Picture of TH type bucket elevator:

How to choose bucket elevator suitable for you : 1. How about the capacity? Such as 5t/h,10t/h,20t/h etc. 2. What’s you need lifting height? Such as 5m,20m,50m,100m etc. 3. What’s material you need lifting? Such as coal, cement, stone, grain etc. Tell me those data, we can help you choose the suitable bucket elevator for you. Packaging & Shipping 1. Main part and relative valves, instrument: composite material box packed, rain-proof. 2. Will be marked on per part with the regulations on goods. 3. Steel parts will be loaded into container directly Our Services Quality Assurance: One year Quality warranty period (after put into operation formally). During the warranty period, if occurred due to the goods themselves cause malfunction or damage, the Company will guide maintenance or replacement of the corresponding parts without pay, if need to go site, buyer charge the transport fee and accommodation of engineer. Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price. Company Information Shijiazhuang Kuofu Complete Machinery Equipment CO.,Ltd is established in the year of 2002 and located in Shijiazhuang, Hebei Province where is near Beijing and Tianjin. We organize the production in strict accordance with ISO9001:2000 standard quality management system and use 3D entity design software as well as CAD, CAPD technology to constantly design and develop new products in order to satisfy the demand of more industry and higher level with our scientific and perfect quality assurance and timely and thoughtful after-sales service. We guarantee our design is completely in conformity with customer's previous program plan and the equipment operates smoothly. Our Main Products:

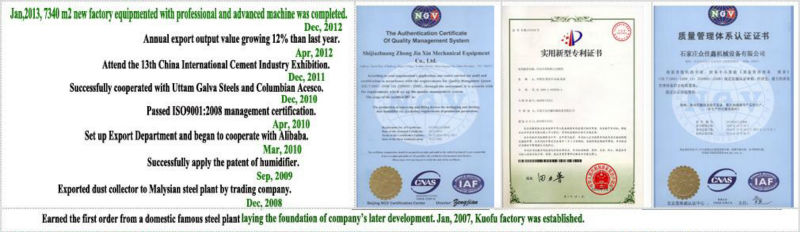

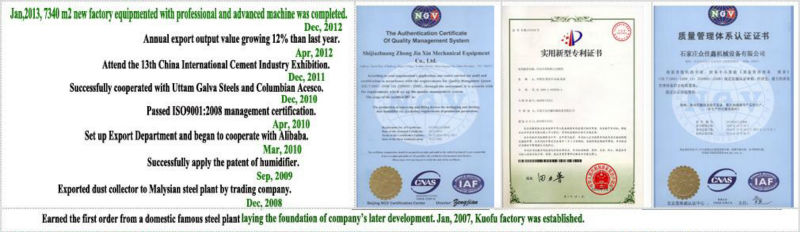

How to choose bucket elevator suitable for you : 1. How about the capacity? Such as 5t/h,10t/h,20t/h etc. 2. What’s you need lifting height? Such as 5m,20m,50m,100m etc. 3. What’s material you need lifting? Such as coal, cement, stone, grain etc. Tell me those data, we can help you choose the suitable bucket elevator for you. Packaging & Shipping 1. Main part and relative valves, instrument: composite material box packed, rain-proof. 2. Will be marked on per part with the regulations on goods. 3. Steel parts will be loaded into container directly Our Services Quality Assurance: One year Quality warranty period (after put into operation formally). During the warranty period, if occurred due to the goods themselves cause malfunction or damage, the Company will guide maintenance or replacement of the corresponding parts without pay, if need to go site, buyer charge the transport fee and accommodation of engineer. Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price. Company Information Shijiazhuang Kuofu Complete Machinery Equipment CO.,Ltd is established in the year of 2002 and located in Shijiazhuang, Hebei Province where is near Beijing and Tianjin. We organize the production in strict accordance with ISO9001:2000 standard quality management system and use 3D entity design software as well as CAD, CAPD technology to constantly design and develop new products in order to satisfy the demand of more industry and higher level with our scientific and perfect quality assurance and timely and thoughtful after-sales service. We guarantee our design is completely in conformity with customer's previous program plan and the equipment operates smoothly. Our Main Products:

1. Conveying Equipment__ Pneumatic conveying system,

Bucket Elevator, Scraper Conveyor, Screw Conveyor, Belt Conveyor,

2. Dust-cleaning Equipment __Bag Filter Dust Collector,ESP Dust Collector, Cyclone Dust Collector

3. Patented Product__ Dust Humidifier.

4. Complete Cement production line equipment

Kindly contact with us at any time

2. Using the assembled sprocket.This bucket elevator by wheel body, flange with high strength bolt composition .After the sprocket wheel wear to a certain degree, it can be unscrewed the bolt, changing a wheel rim, easy to change, and save material, reduce the maintenance costs;

3. The lower part using the heavy hammer lever tensioning device, automatic tension can be realized. After an installation does not need to adjust, and can keep constant tension, to ensure the normal operation of the machine, and avoid the skid or take off the chain;

4. Traction with high strength low alloy ring chain, after proper heat treatment, has the very high tensile strength and wear resistance, long service life.

Technical parameters for your reference :

Type of Bucket Elevator | TH315 | TH400 | TH500 | TH630 | ||||||

Type of Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||

Delivery Value(M3/H) | 35 | 59 | 58 | 94 | 73 | 118 | 114 | 185 | ||

Bucket Capacity(L) | 3.75 | 6 | 5.9 | 9.5 | 9.3 | 15 | 14.5 | 23.6 | ||

Bucket Distance(MM) | 512 | 688 | ||||||||

Speed of Bucket(M/S) | 1.4 | 1.5 | ||||||||

Drive sprockets rotation Speed(RPM) | 42.5 | 37.6 | 35.3 | 31.8 | ||||||

Picture of TH type bucket elevator:

How to choose bucket elevator suitable for you : 1. How about the capacity? Such as 5t/h,10t/h,20t/h etc. 2. What’s you need lifting height? Such as 5m,20m,50m,100m etc. 3. What’s material you need lifting? Such as coal, cement, stone, grain etc. Tell me those data, we can help you choose the suitable bucket elevator for you. Packaging & Shipping 1. Main part and relative valves, instrument: composite material box packed, rain-proof. 2. Will be marked on per part with the regulations on goods. 3. Steel parts will be loaded into container directly Our Services Quality Assurance: One year Quality warranty period (after put into operation formally). During the warranty period, if occurred due to the goods themselves cause malfunction or damage, the Company will guide maintenance or replacement of the corresponding parts without pay, if need to go site, buyer charge the transport fee and accommodation of engineer. Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price. Company Information Shijiazhuang Kuofu Complete Machinery Equipment CO.,Ltd is established in the year of 2002 and located in Shijiazhuang, Hebei Province where is near Beijing and Tianjin. We organize the production in strict accordance with ISO9001:2000 standard quality management system and use 3D entity design software as well as CAD, CAPD technology to constantly design and develop new products in order to satisfy the demand of more industry and higher level with our scientific and perfect quality assurance and timely and thoughtful after-sales service. We guarantee our design is completely in conformity with customer's previous program plan and the equipment operates smoothly. Our Main Products:

How to choose bucket elevator suitable for you : 1. How about the capacity? Such as 5t/h,10t/h,20t/h etc. 2. What’s you need lifting height? Such as 5m,20m,50m,100m etc. 3. What’s material you need lifting? Such as coal, cement, stone, grain etc. Tell me those data, we can help you choose the suitable bucket elevator for you. Packaging & Shipping 1. Main part and relative valves, instrument: composite material box packed, rain-proof. 2. Will be marked on per part with the regulations on goods. 3. Steel parts will be loaded into container directly Our Services Quality Assurance: One year Quality warranty period (after put into operation formally). During the warranty period, if occurred due to the goods themselves cause malfunction or damage, the Company will guide maintenance or replacement of the corresponding parts without pay, if need to go site, buyer charge the transport fee and accommodation of engineer. Provide technical guide forever. After Quality Warranty period, will provide the spare parts with cost price. Company Information Shijiazhuang Kuofu Complete Machinery Equipment CO.,Ltd is established in the year of 2002 and located in Shijiazhuang, Hebei Province where is near Beijing and Tianjin. We organize the production in strict accordance with ISO9001:2000 standard quality management system and use 3D entity design software as well as CAD, CAPD technology to constantly design and develop new products in order to satisfy the demand of more industry and higher level with our scientific and perfect quality assurance and timely and thoughtful after-sales service. We guarantee our design is completely in conformity with customer's previous program plan and the equipment operates smoothly. Our Main Products: 1. Conveying Equipment__ Pneumatic conveying system,

Bucket Elevator, Scraper Conveyor, Screw Conveyor, Belt Conveyor,

2. Dust-cleaning Equipment __Bag Filter Dust Collector,ESP Dust Collector, Cyclone Dust Collector

3. Patented Product__ Dust Humidifier.

4. Complete Cement production line equipment

Kindly contact with us at any time

Related Keywords

Related Keywords

You May Also Like

You May Also Like