Pneumatic Dust Ash transport System 3T/H for Dry Powder

- Delivery Time:

- 60 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

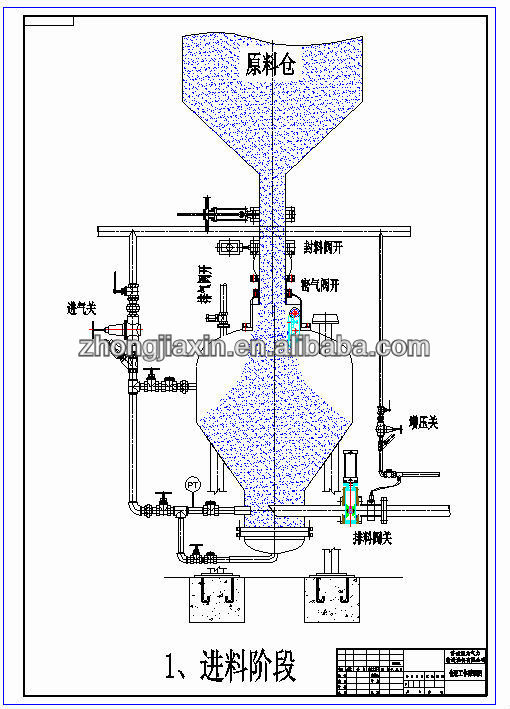

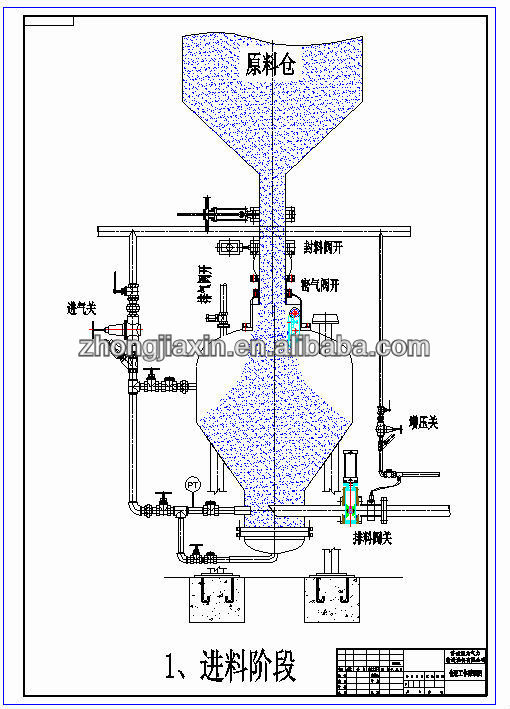

Pneumatic Dust Ash transport System 3T/H for Dry Powder  Pneumatic Transport System Structure: storehouse pump mainly consist of the pump top storehouse, pump body, feeding valve, unloader device, intake pipe road, automatic control system, the exhaust valve etc. Storehouse pump divided into the single storehouse pump and double storehouse pump, The former is intermittent transmission, another consist of two sets of pump body which can work by turns, in order to achieve continuous delivery of materials. Pneumatic Transport System Characteristics: 1. Storehouse pump style pump with a long transmission distance, flexible piping, saving equipment investment, etc.,can be horizontal transport and vertical transmission, transmission distance can reach 1 km. 2. Storehouse pump has a good capacity of conveying, the output of desktop can be up to 50 cubic meters with low energy consumption and low noise 3. With high degree of automation control system which can automatically feeding ,conveying, measure, countting, display, alarm, easy to operate, piping flexibility, small footprint. 4. Gas control system. The gas resource of warehouse pump is the recycling waste gas from steel plant. 5. Good sealing. Material run in a closed pipe, no dust, environment protect. Reliable operation, less wearing parts, easy to maintenance, long life span of 3~5 years. Pneumatic Conveyor System Parameters:

Pneumatic Transport System Structure: storehouse pump mainly consist of the pump top storehouse, pump body, feeding valve, unloader device, intake pipe road, automatic control system, the exhaust valve etc. Storehouse pump divided into the single storehouse pump and double storehouse pump, The former is intermittent transmission, another consist of two sets of pump body which can work by turns, in order to achieve continuous delivery of materials. Pneumatic Transport System Characteristics: 1. Storehouse pump style pump with a long transmission distance, flexible piping, saving equipment investment, etc.,can be horizontal transport and vertical transmission, transmission distance can reach 1 km. 2. Storehouse pump has a good capacity of conveying, the output of desktop can be up to 50 cubic meters with low energy consumption and low noise 3. With high degree of automation control system which can automatically feeding ,conveying, measure, countting, display, alarm, easy to operate, piping flexibility, small footprint. 4. Gas control system. The gas resource of warehouse pump is the recycling waste gas from steel plant. 5. Good sealing. Material run in a closed pipe, no dust, environment protect. Reliable operation, less wearing parts, easy to maintenance, long life span of 3~5 years. Pneumatic Conveyor System Parameters:

Each unit process: feeding→pressure to boiling→fluidify→reture to zero→next unit.

Parameter includes: 1. What's the material you are going to deal with ? 2. What are the physical characteristics of the material? Such as the size,temperature,density,moisture content,etc 3 . What's the producing capacity you are going to achive? Company Introduction &Main Products: Established in 2002 year, pass ISO9001:2008 Industry Dust collector- Bag Filter, ESP, Cyclone Dust Collector Bucket Elevator Scraper Conveyor Screw Conveyor Pneumatic Conveyor

Parameter includes: 1. What's the material you are going to deal with ? 2. What are the physical characteristics of the material? Such as the size,temperature,density,moisture content,etc 3 . What's the producing capacity you are going to achive? Company Introduction &Main Products: Established in 2002 year, pass ISO9001:2008 Industry Dust collector- Bag Filter, ESP, Cyclone Dust Collector Bucket Elevator Scraper Conveyor Screw Conveyor Pneumatic Conveyor

Pneumatic Transport System Structure: storehouse pump mainly consist of the pump top storehouse, pump body, feeding valve, unloader device, intake pipe road, automatic control system, the exhaust valve etc. Storehouse pump divided into the single storehouse pump and double storehouse pump, The former is intermittent transmission, another consist of two sets of pump body which can work by turns, in order to achieve continuous delivery of materials. Pneumatic Transport System Characteristics: 1. Storehouse pump style pump with a long transmission distance, flexible piping, saving equipment investment, etc.,can be horizontal transport and vertical transmission, transmission distance can reach 1 km. 2. Storehouse pump has a good capacity of conveying, the output of desktop can be up to 50 cubic meters with low energy consumption and low noise 3. With high degree of automation control system which can automatically feeding ,conveying, measure, countting, display, alarm, easy to operate, piping flexibility, small footprint. 4. Gas control system. The gas resource of warehouse pump is the recycling waste gas from steel plant. 5. Good sealing. Material run in a closed pipe, no dust, environment protect. Reliable operation, less wearing parts, easy to maintenance, long life span of 3~5 years. Pneumatic Conveyor System Parameters:

Pneumatic Transport System Structure: storehouse pump mainly consist of the pump top storehouse, pump body, feeding valve, unloader device, intake pipe road, automatic control system, the exhaust valve etc. Storehouse pump divided into the single storehouse pump and double storehouse pump, The former is intermittent transmission, another consist of two sets of pump body which can work by turns, in order to achieve continuous delivery of materials. Pneumatic Transport System Characteristics: 1. Storehouse pump style pump with a long transmission distance, flexible piping, saving equipment investment, etc.,can be horizontal transport and vertical transmission, transmission distance can reach 1 km. 2. Storehouse pump has a good capacity of conveying, the output of desktop can be up to 50 cubic meters with low energy consumption and low noise 3. With high degree of automation control system which can automatically feeding ,conveying, measure, countting, display, alarm, easy to operate, piping flexibility, small footprint. 4. Gas control system. The gas resource of warehouse pump is the recycling waste gas from steel plant. 5. Good sealing. Material run in a closed pipe, no dust, environment protect. Reliable operation, less wearing parts, easy to maintenance, long life span of 3~5 years. Pneumatic Conveyor System Parameters: Parameters | L-0.8 | L-1.2 | L-1.4 | L-1.6 | L-1.8 | L-2.0 | L-2.2 | L-2.4 |

Body Inner Diam.(mm) | 800 | 1200 | 1400 | 1600 | 1800 | 2000 | 22000 | 24000 |

Total volume(M^3) | 0.35 | 1.32 | 2.15 | 3.0 | 4.12 | 5.0 | 7.5 | 9.25 |

Operation Temp.(°C) | ≤120 | |||||||

Max. design pressure(Mpa) | 0.78 | |||||||

Operation Pressure(Mpa) | 0.2-0.5(Basis on the conveying disance and conveying material) | |||||||

Body materail | Q235-B | |||||||

Max. conveying distance(m) | 500~1500M | |||||||

Outlet conveying Diam | DN50 | DN100/DN125 | DN125/DN15 | |||||

Mixing ratio | 50 | 60 | 60 | 60 | 60 | 60 | 70 | 70 |

Capacity(t/h) | 5 | 12 | 20 | 25 | 30 | 35 | 45 | 55 |

Air consumption (m^3/min) | 2 | 6 | 6~10 | 10~20 | 16~20 | |||

Related Keywords

Related Keywords

You May Also Like

You May Also Like