Anti impact application repair grip rebar couplers portable steel bar connectors

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Product Description 1. Rebar Grade: compliance with Eurocode 2, BS 8110, DIN 1045, ACI 318, IBC, AASHTO, ASME Sec III Div 2,ASTM Standard. 2. Size: reinforcing bars Ø12 to 50 mm 3. Brand:HBYD,Patented technology. 4. Certification: ISO9001, D&B,CE,DCL.

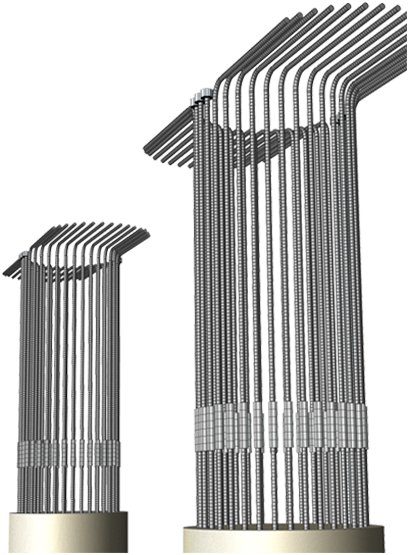

Products Show Product Details: 1.Hebei Yida Anti Impact Rebar Coupling system is divided into the following types:

(1)ACJ Standard Coupler 2.1

(2)BCJ Transition Coupler 2.2

(3)FCJ Positive and negative Thread Coupler 2.3

(4)KCJ Adjustable Coupler 2.4

(5)MCJ Anchorage Terminator Coupler 2.5

2. Introduction

Hebei Yida Anti Impact Rebar Coupling system is a mechanical rebar splicing system, be made of high quality alloy steel. It has already passed the High Speed Tensile test of Anti instant impact by Germany Berlin BAM Laboratory. It has been widely applied at the sites where required high level of resistance to impact. The coupler sleeve will be perfect connected with rebar by cold swaged deformation in the application, and dual couplers will be connected by a high strength bolt.

Special Advantages:

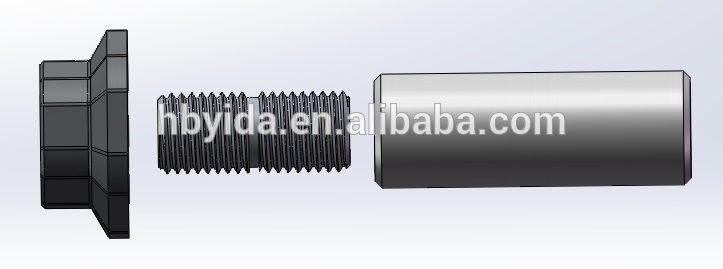

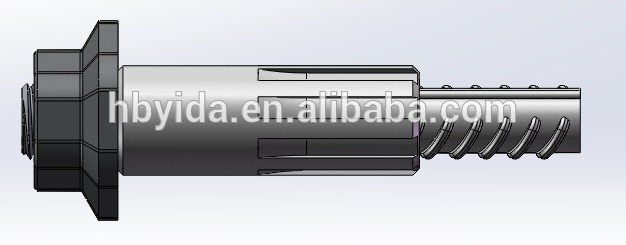

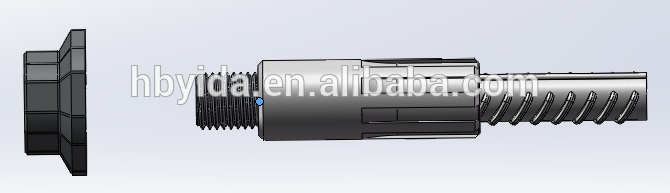

(1)Each rebar is connected by cold swaged with a coupling, It was processed by large-tonnage hydraulic machine and unique split mould to ensure high quality and reliable radial deformation swage. Connection of rebar with coupler after swaged as shown in Figure 1.

Figure 1

(2)Rebar sleeve bond press is done prior to site connection saving precious site time.

(3)The two sleeves are connected through a high-strength bolt, quality ensured.

(4)Installation on site is easy and fast, even in dense cages. No X-ray check is needed and installation can be done in any weather conditions.

(5)No thread cutting, no need heat or pre-heat on rebar, hence the rebar retains its original characteristics after splice.

(6)The Yida ACJ rebar coupling system stands complex or full tension as well as full compression state.

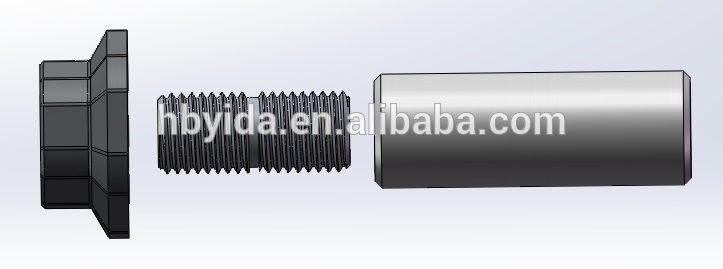

2.1ACJ Standard Coupler

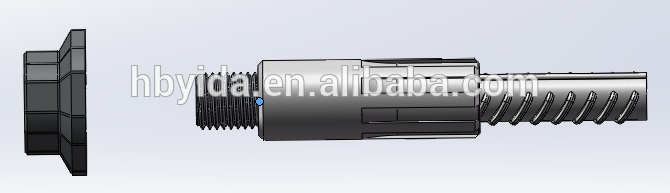

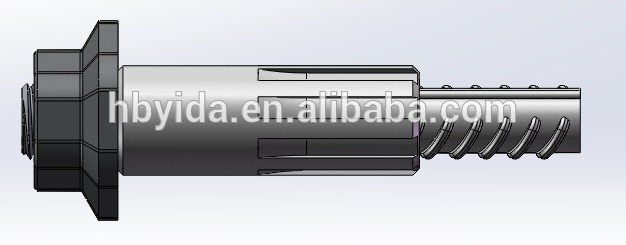

ACJ standard coupler is made up by two standard sleeves and one standard bolt (as shown in Figure 2), suitable for same diameter rebar connecting. The Yida ACJ is suitable for general application such as beams or walls where the rotation

of the rebar is possible. Screw the bolt into one sleeve firstly, then rotate one rebar to screw the other bolt end into the other sleeve.

Figure 2

Characteristic:ACJ coupler uses standard female (sleeve) only, making rebar press more efficient as there is no need to specify different sleeves.

Application Guide:

Proper installation is very important to ensure the design load will be reached in the application. Yida strongly recommends that the installation and site quality check be done according to the required guidelines and dimensions.

● Rebar And sleeves swaged connection

Using hydraulic machine and unique split mould to swage sleeve deformation, formed the seamless connection with rebar and the swage length is to meet the standard swage length. Shorter swage length reduces the bond, while longer swage length may shorten the engagement length of the thread.

● Site installation method

Step 1:Screw the bolt into female coupler swaged with rebar, till unable to screw continually. As shown in Figure 3.

Figure 3

Step 2:Screw another side of bolt into the other sleeve after swaged with rebar, till unable to screw continually. As shown in Figure 4.

Figure 4

Step 3:With help of two pipe wrench, tighten the connection by turning both rebar / couplers in opposite direction at the same time.

Our Company

Our Company

Factory HBYD Workshop HBYD

Factory HBYD Workshop HBYD

Workshop HBYD Work shop HBYD

Workshop HBYD Work shop HBYD  Packing & Delivery Packing Details : Packing with carton box,and waterproof plastic bag inside,Then put into wooden case. Delivery Details : 7-30 days after order of hydraulic grip coupler splice.

Packing & Delivery Packing Details : Packing with carton box,and waterproof plastic bag inside,Then put into wooden case. Delivery Details : 7-30 days after order of hydraulic grip coupler splice.

1. Special logistics packaging 2. grip coupler products 3. water proof package

1. Special logistics packaging 2. grip coupler products 3. water proof package

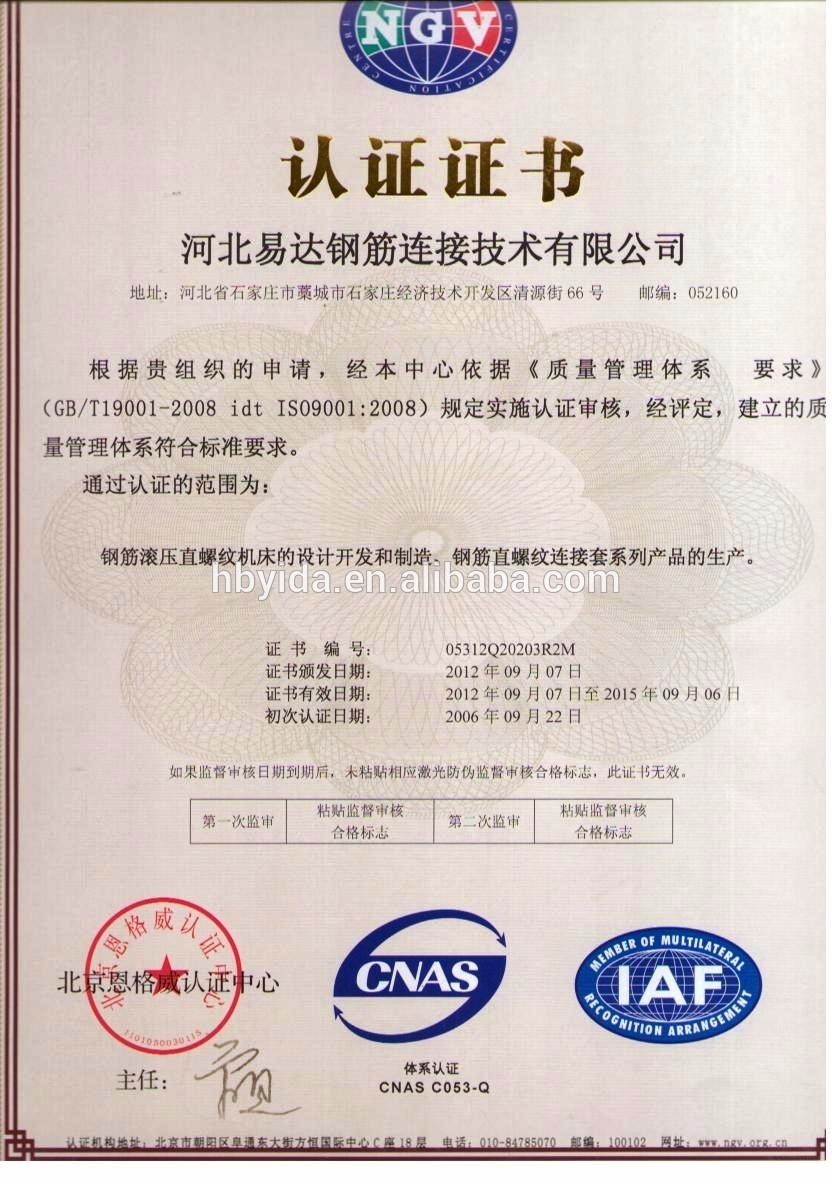

4. Professional packaged 5. fixed pallet 6. wooden case Our Certifications

4. Professional packaged 5. fixed pallet 6. wooden case Our Certifications

Why I chose Grip Coupler: Positive mechanical interlock

Why I chose Grip Coupler: Positive mechanical interlock

Powerful range of hydraulic presses

Splices for all bar sizes US and International

Choices for Type 1, Type 2 or higher

Black or Galvanized or Epoxy coated bars

New construction repair or retrofit

Field or shop-field installation

Sheared, flame or saw cut bars

True continuity and load path where you need it

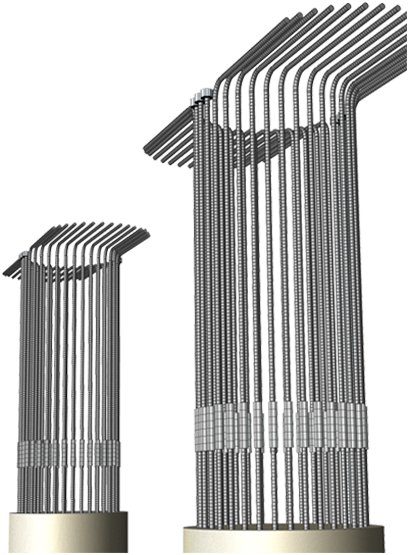

ButtonHead System

Alleviates congestion by replacing hook bars

Same cold-swage technology as BarGrip

No special thread cutting or chemistry requirements

Head sizes of 5 times and 10 times rebar area

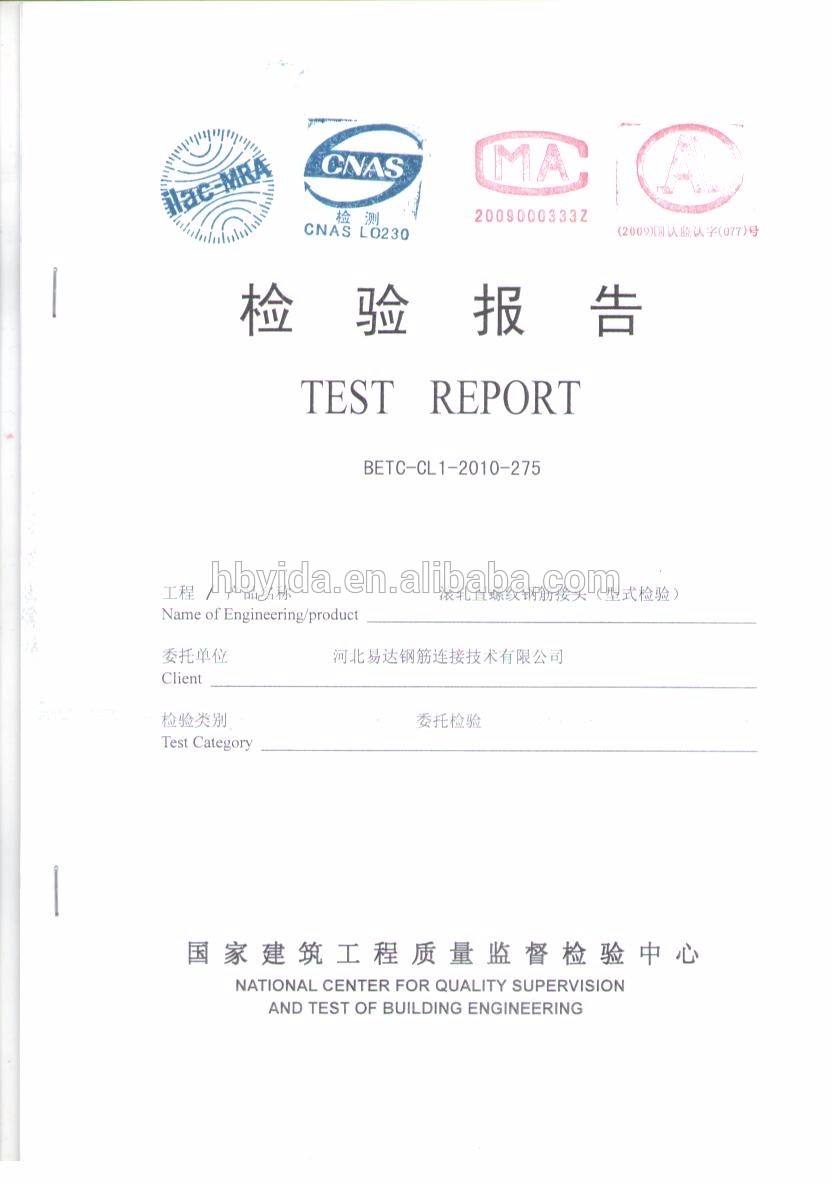

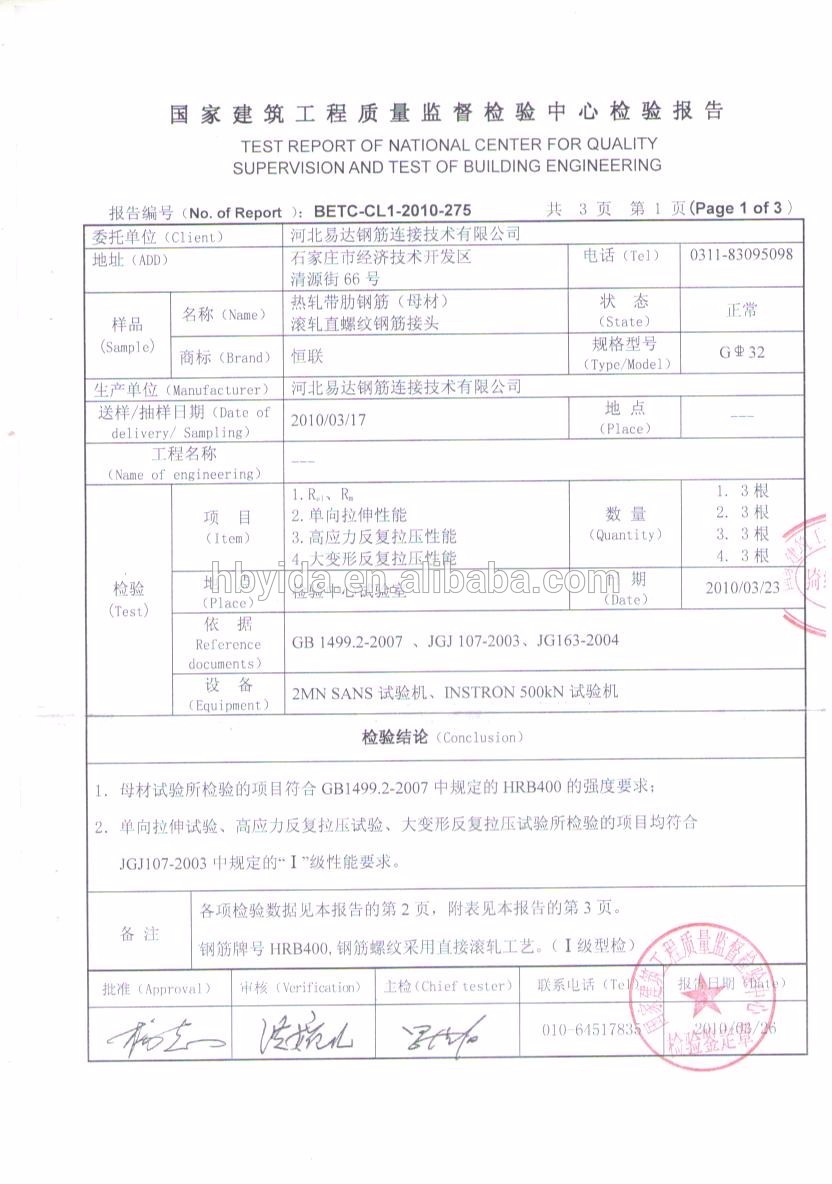

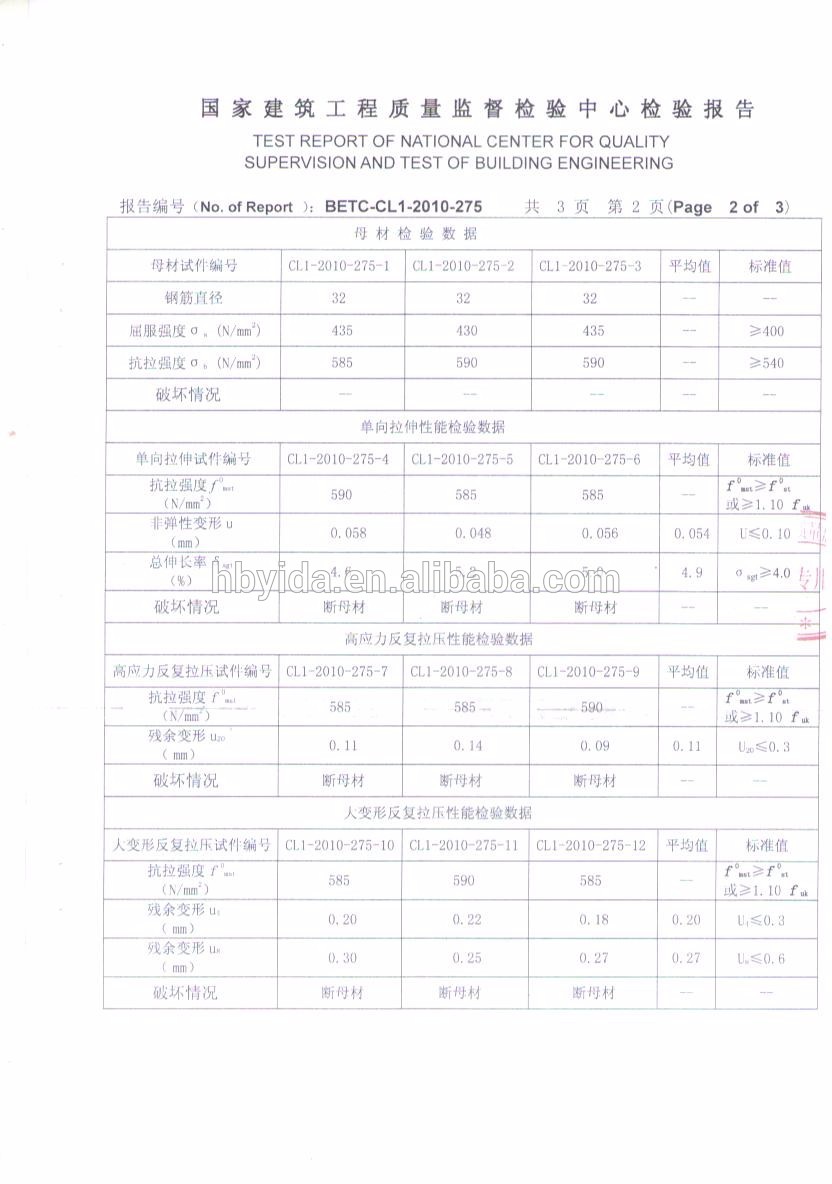

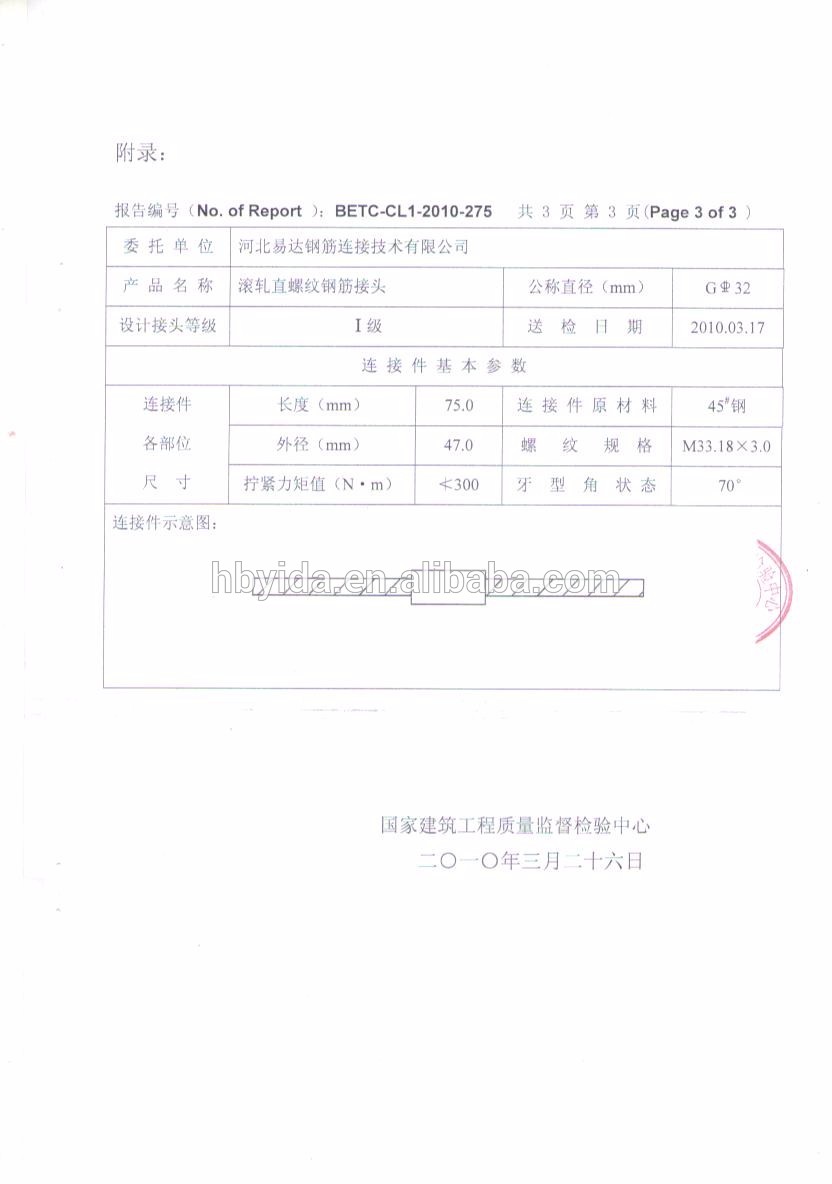

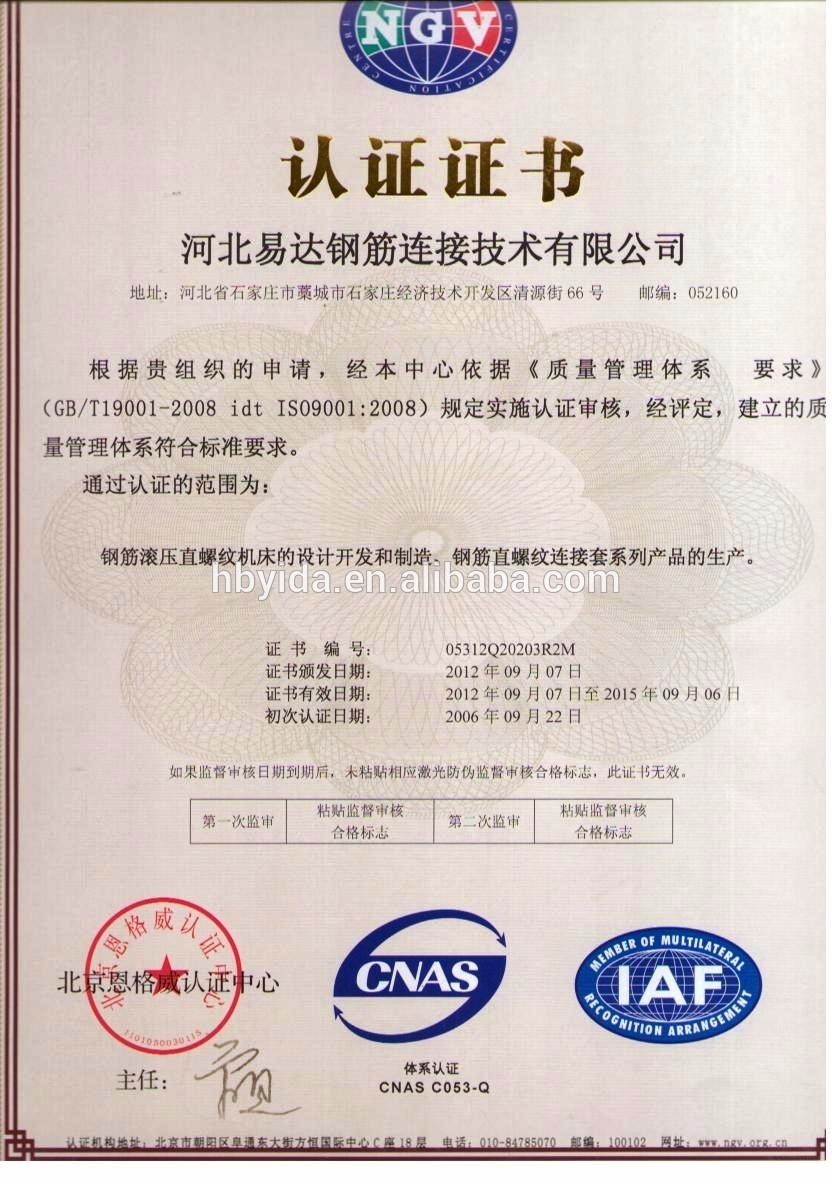

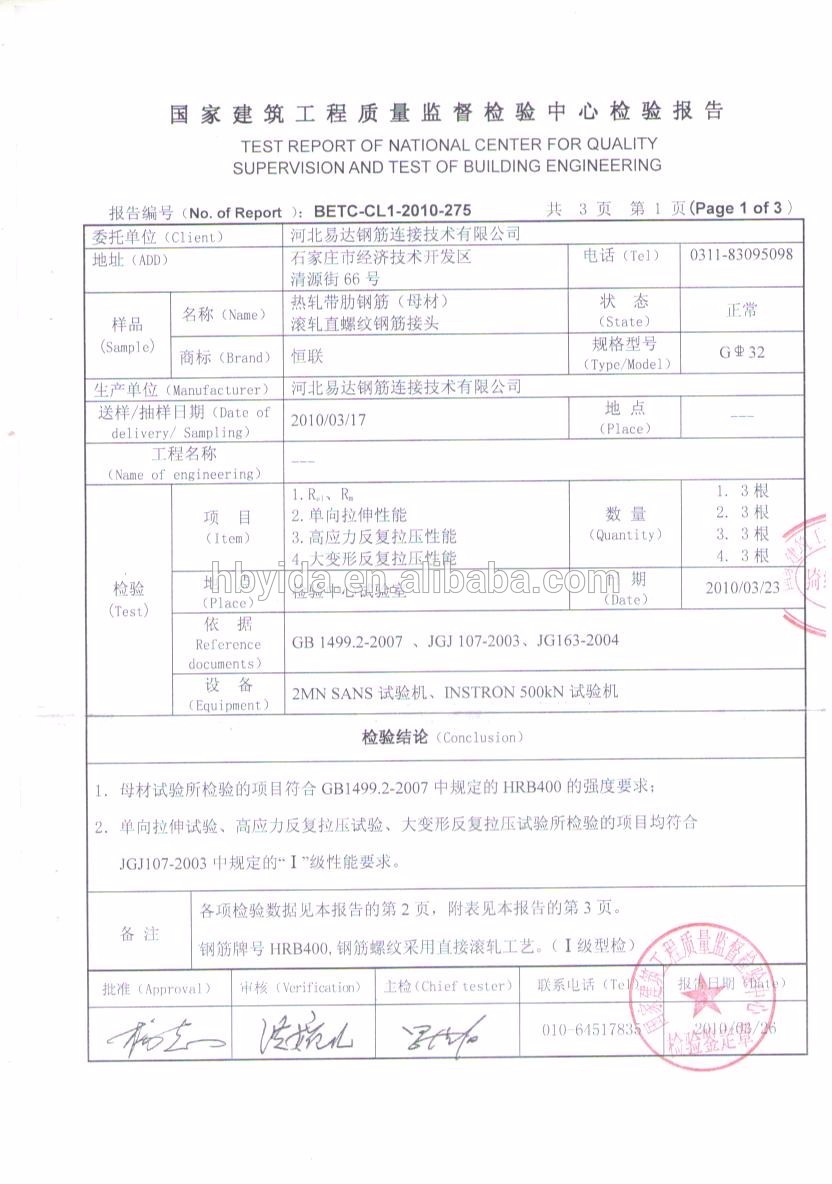

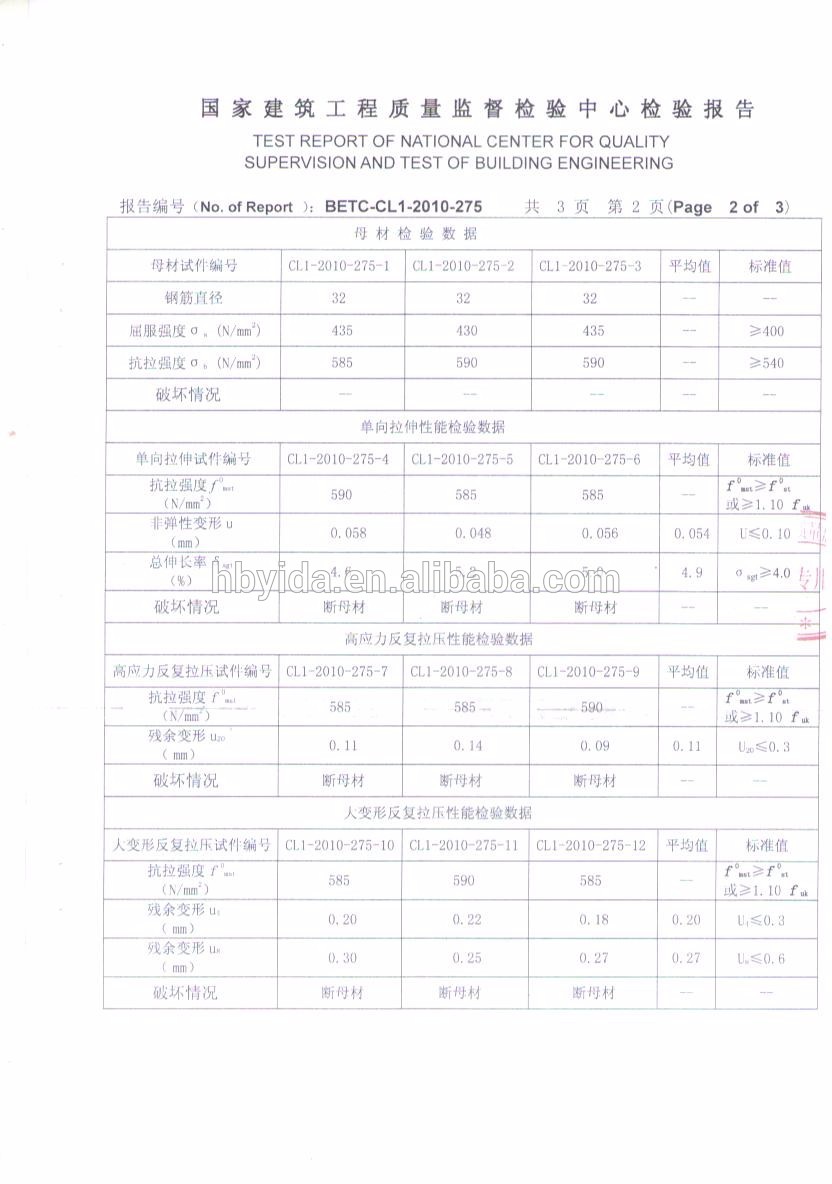

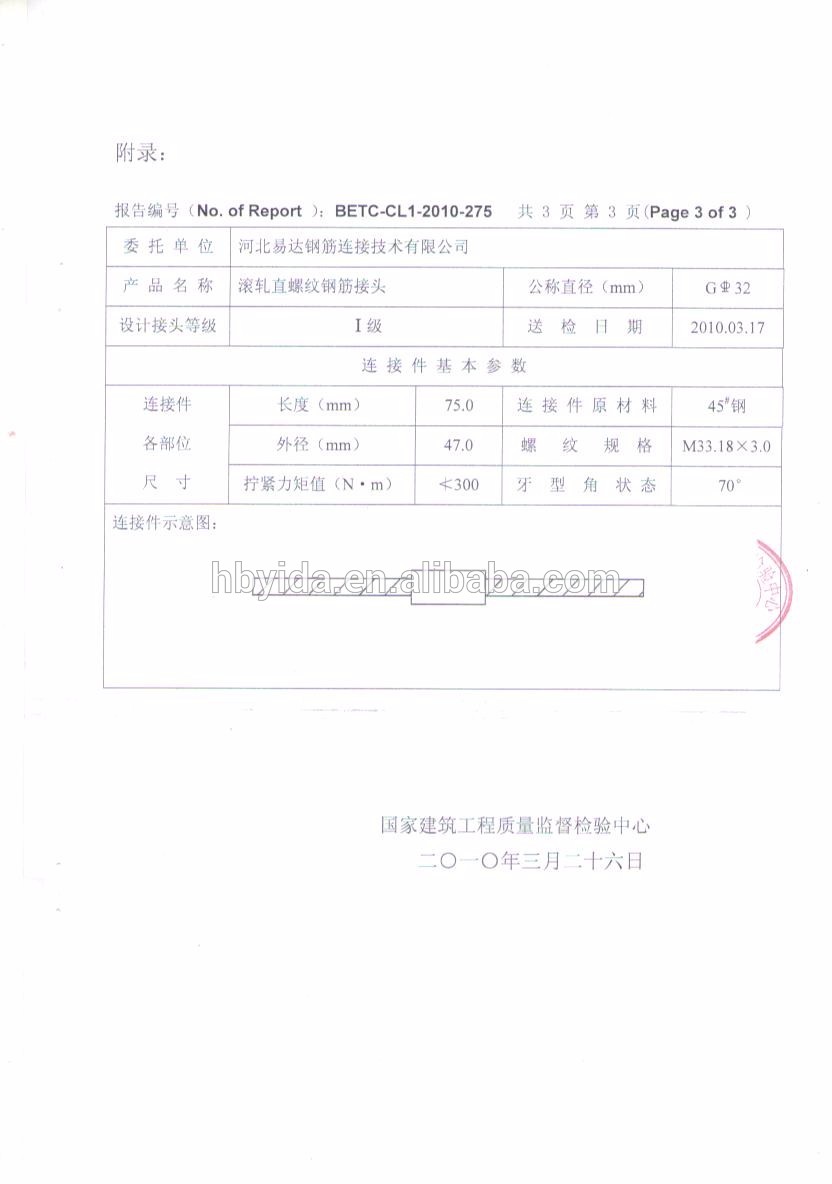

Customer Photo ISO: Strictly quality control and Passed ISO 9001:2008

Test equipments: Tensilse strength test machine.

Test equipments: Tensilse strength test machine.

Favorable Comment Service aftersales abroad can be offered with english engineer.

FAQ Q: Are you trading company or manufacturer ? A: We are factory,the top level headed manufacture for rebar couplers and thread machine since 1992.

FAQ Q: Are you trading company or manufacturer ? A: We are factory,the top level headed manufacture for rebar couplers and thread machine since 1992.

Q: How long is your delivery time? A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ? A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ? A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Related Products Anchorage Terminator coupler: 2.5 MCJ Anchorage Terminator Coupler

MCJ Anchorage Terminator Coupler is made up by one standard sleeve, one standard bolt, and one standard anchorage terminator coupler (as shown in Figure 16),used for the connection between rebar and anchorage terminator coupler. It can be used when need using anchorage terminator coupler to connect with rebar.

Figure 16

Characteristic:MCJ Coupler is using standard sleeve, standard bolt to make the rebar connected with anchorage terminator coupler so that can satisfy the anti impact requirement.

● Rebar And sleeves swaged connection

Using hydraulic machine and unique split mould to swage sleeve deformation, formed the seamless connection with rebar and the swage length is to meet the standard swage length. Shorter swage length reduces the bond, while longer swage length may shorten the engagement length of the thread.

● Site Installation Method

Step 1:Screw the standard bolt into female coupler swaged with rebar, till unable to screw continually. As shown in Figure 17.

Figure 17

Step 2: Screw the anchorage terminator coupler into standard bolt, make the anchorage terminator coupler keep touch with female coupler. As shown in Figure 18.

Figure 18

Step 3: With help of two pipe wrench, tighten the connection by turning both two sleeves in opposite direction at the same time.

(1)ACJ Standard Coupler 2.1

(2)BCJ Transition Coupler 2.2

(3)FCJ Positive and negative Thread Coupler 2.3

(4)KCJ Adjustable Coupler 2.4

(5)MCJ Anchorage Terminator Coupler 2.5

2. Introduction

Hebei Yida Anti Impact Rebar Coupling system is a mechanical rebar splicing system, be made of high quality alloy steel. It has already passed the High Speed Tensile test of Anti instant impact by Germany Berlin BAM Laboratory. It has been widely applied at the sites where required high level of resistance to impact. The coupler sleeve will be perfect connected with rebar by cold swaged deformation in the application, and dual couplers will be connected by a high strength bolt.

Special Advantages:

(1)Each rebar is connected by cold swaged with a coupling, It was processed by large-tonnage hydraulic machine and unique split mould to ensure high quality and reliable radial deformation swage. Connection of rebar with coupler after swaged as shown in Figure 1.

Figure 1

(2)Rebar sleeve bond press is done prior to site connection saving precious site time.

(3)The two sleeves are connected through a high-strength bolt, quality ensured.

(4)Installation on site is easy and fast, even in dense cages. No X-ray check is needed and installation can be done in any weather conditions.

(5)No thread cutting, no need heat or pre-heat on rebar, hence the rebar retains its original characteristics after splice.

(6)The Yida ACJ rebar coupling system stands complex or full tension as well as full compression state.

2.1ACJ Standard Coupler

ACJ standard coupler is made up by two standard sleeves and one standard bolt (as shown in Figure 2), suitable for same diameter rebar connecting. The Yida ACJ is suitable for general application such as beams or walls where the rotation

of the rebar is possible. Screw the bolt into one sleeve firstly, then rotate one rebar to screw the other bolt end into the other sleeve.

Figure 2

Characteristic:ACJ coupler uses standard female (sleeve) only, making rebar press more efficient as there is no need to specify different sleeves.

Application Guide:

Proper installation is very important to ensure the design load will be reached in the application. Yida strongly recommends that the installation and site quality check be done according to the required guidelines and dimensions.

● Rebar And sleeves swaged connection

Using hydraulic machine and unique split mould to swage sleeve deformation, formed the seamless connection with rebar and the swage length is to meet the standard swage length. Shorter swage length reduces the bond, while longer swage length may shorten the engagement length of the thread.

● Site installation method

Step 1:Screw the bolt into female coupler swaged with rebar, till unable to screw continually. As shown in Figure 3.

Figure 3

Step 2:Screw another side of bolt into the other sleeve after swaged with rebar, till unable to screw continually. As shown in Figure 4.

Figure 4

Step 3:With help of two pipe wrench, tighten the connection by turning both rebar / couplers in opposite direction at the same time.

Our Company

Our Company

Factory HBYD Workshop HBYD

Factory HBYD Workshop HBYD

Workshop HBYD Work shop HBYD

Workshop HBYD Work shop HBYD  Packing & Delivery Packing Details : Packing with carton box,and waterproof plastic bag inside,Then put into wooden case. Delivery Details : 7-30 days after order of hydraulic grip coupler splice.

Packing & Delivery Packing Details : Packing with carton box,and waterproof plastic bag inside,Then put into wooden case. Delivery Details : 7-30 days after order of hydraulic grip coupler splice.

1. Special logistics packaging 2. grip coupler products 3. water proof package

1. Special logistics packaging 2. grip coupler products 3. water proof package

4. Professional packaged 5. fixed pallet 6. wooden case Our Certifications

4. Professional packaged 5. fixed pallet 6. wooden case Our Certifications

Why I chose Grip Coupler: Positive mechanical interlock

Why I chose Grip Coupler: Positive mechanical interlockPowerful range of hydraulic presses

Splices for all bar sizes US and International

Choices for Type 1, Type 2 or higher

Black or Galvanized or Epoxy coated bars

New construction repair or retrofit

Field or shop-field installation

Sheared, flame or saw cut bars

True continuity and load path where you need it

ButtonHead System

Alleviates congestion by replacing hook bars

Same cold-swage technology as BarGrip

No special thread cutting or chemistry requirements

Head sizes of 5 times and 10 times rebar area

Customer Photo ISO: Strictly quality control and Passed ISO 9001:2008

Test equipments: Tensilse strength test machine.

Test equipments: Tensilse strength test machine.Favorable Comment Service aftersales abroad can be offered with english engineer.

FAQ Q: Are you trading company or manufacturer ? A: We are factory,the top level headed manufacture for rebar couplers and thread machine since 1992.

FAQ Q: Are you trading company or manufacturer ? A: We are factory,the top level headed manufacture for rebar couplers and thread machine since 1992.Q: How long is your delivery time? A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ? A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ? A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Related Products Anchorage Terminator coupler: 2.5 MCJ Anchorage Terminator Coupler

MCJ Anchorage Terminator Coupler is made up by one standard sleeve, one standard bolt, and one standard anchorage terminator coupler (as shown in Figure 16),used for the connection between rebar and anchorage terminator coupler. It can be used when need using anchorage terminator coupler to connect with rebar.

Figure 16

Characteristic:MCJ Coupler is using standard sleeve, standard bolt to make the rebar connected with anchorage terminator coupler so that can satisfy the anti impact requirement.

● Rebar And sleeves swaged connection

Using hydraulic machine and unique split mould to swage sleeve deformation, formed the seamless connection with rebar and the swage length is to meet the standard swage length. Shorter swage length reduces the bond, while longer swage length may shorten the engagement length of the thread.

● Site Installation Method

Step 1:Screw the standard bolt into female coupler swaged with rebar, till unable to screw continually. As shown in Figure 17.

Figure 17

Step 2: Screw the anchorage terminator coupler into standard bolt, make the anchorage terminator coupler keep touch with female coupler. As shown in Figure 18.

Figure 18

Step 3: With help of two pipe wrench, tighten the connection by turning both two sleeves in opposite direction at the same time.

Related Keywords

Related Keywords