China level headed grip tec rebar splice

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

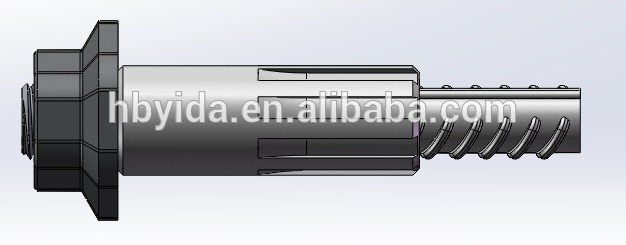

Product Description Hebei Yida Anti Impact Rebar Coupling system is a mechanical rebar splicing system, be made of high quality alloy steel. It has already passed the High Speed Tensile test of Anti instant impact by Germany Berlin BAM Laboratory. It has been widely applied at the sites where required high level of resistance to impact. The coupler sleeve will be perfect connected with rebar by cold swaged deformation in the application, and dual couplers will be connected by a high strength bolt.

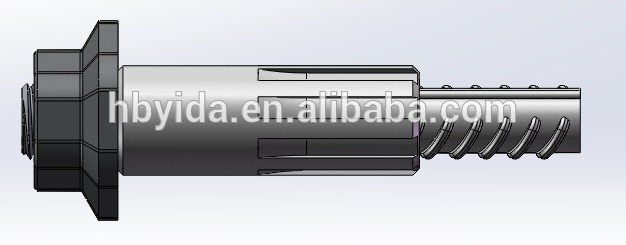

MCJ Anchorage Terminator Coupler is made up by one standard sleeve, one standard bolt, and one standard anchorage terminator coupler,used for the connection between rebar and anchorage terminator coupler. It can be used when need using anchorage terminator coupler to connect with rebar.

Detailed Images

Detailed Images  Characteristic:MCJ Coupler is using standard sleeve, standard bolt to make the rebar connected with anchorage terminator coupler so that can satisfy the anti impact requirement.

Characteristic:MCJ Coupler is using standard sleeve, standard bolt to make the rebar connected with anchorage terminator coupler so that can satisfy the anti impact requirement.

●Rebar And sleeves swaged connection

Using hydraulic machine and unique split mould to swage sleeve deformation, formed the seamless connection with rebar and the swage length is to meet the standard swage length. Shorter swage length reduces the bond, while longer swage length may shorten the engagement length of the thread.

●Site Installation Method

Step 1:Screw the standard bolt into female coupler swaged with rebar, till unable to screw continually.

Step 2: Screw the anchorage terminator coupler into standard bolt, make the anchorage terminator coupler keep touch with female coupler.

Step 3: With help of two pipe wrench, tighten the connection by turning both two sleeves in opposite direction at the same time.

Packing & Delivery Packaging Details: Carton box with waterproof plastic bag to protect our hydraulic grip couplers,then put into wooden case of exporting use, to do the best and safe shippment of Anti impact application repair grip rebar couplers portable steel bar connectors HBYD.

Delivery Detail: Shipped in 3 days after payment

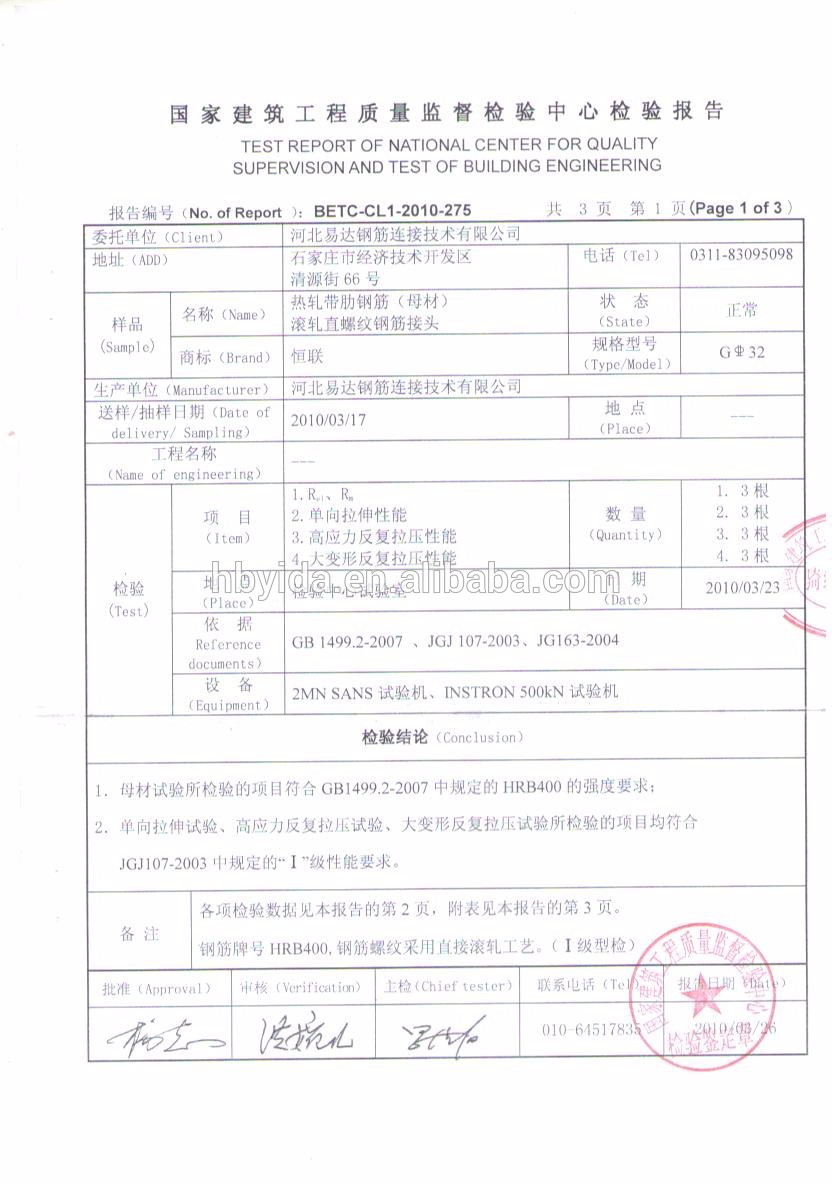

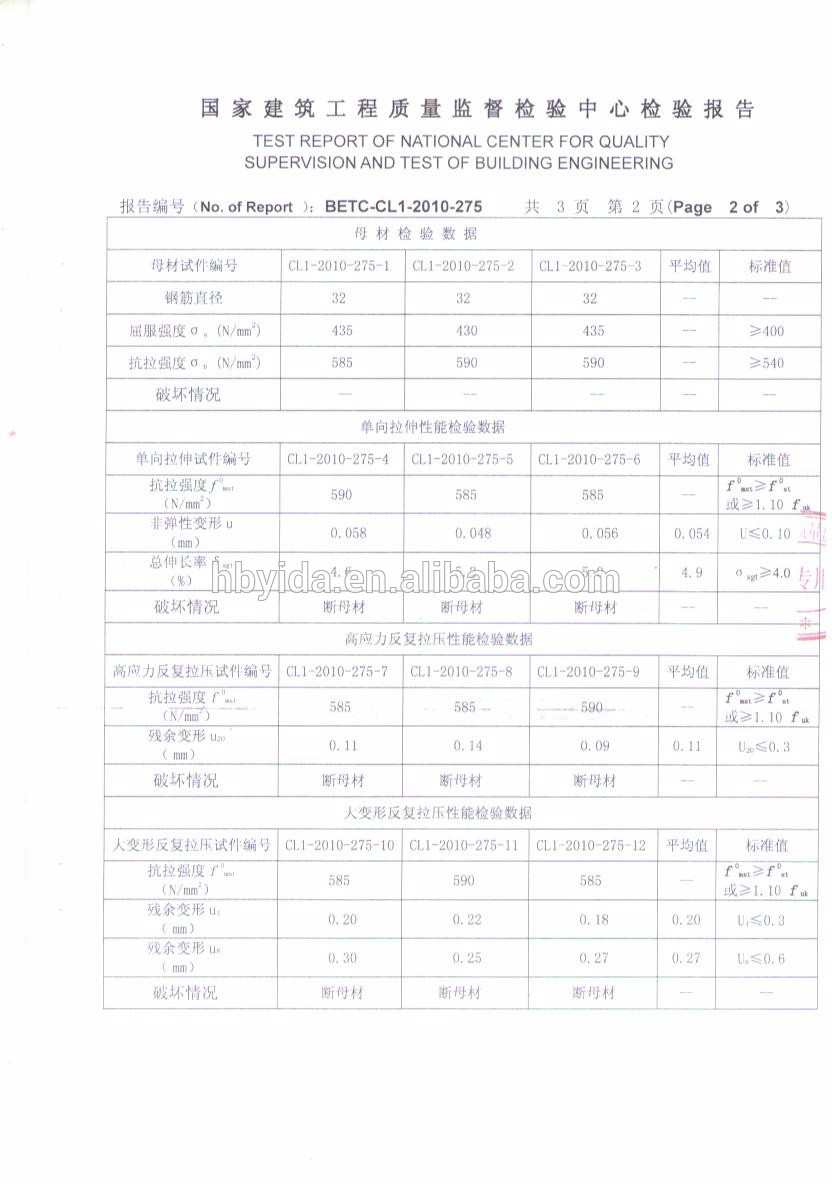

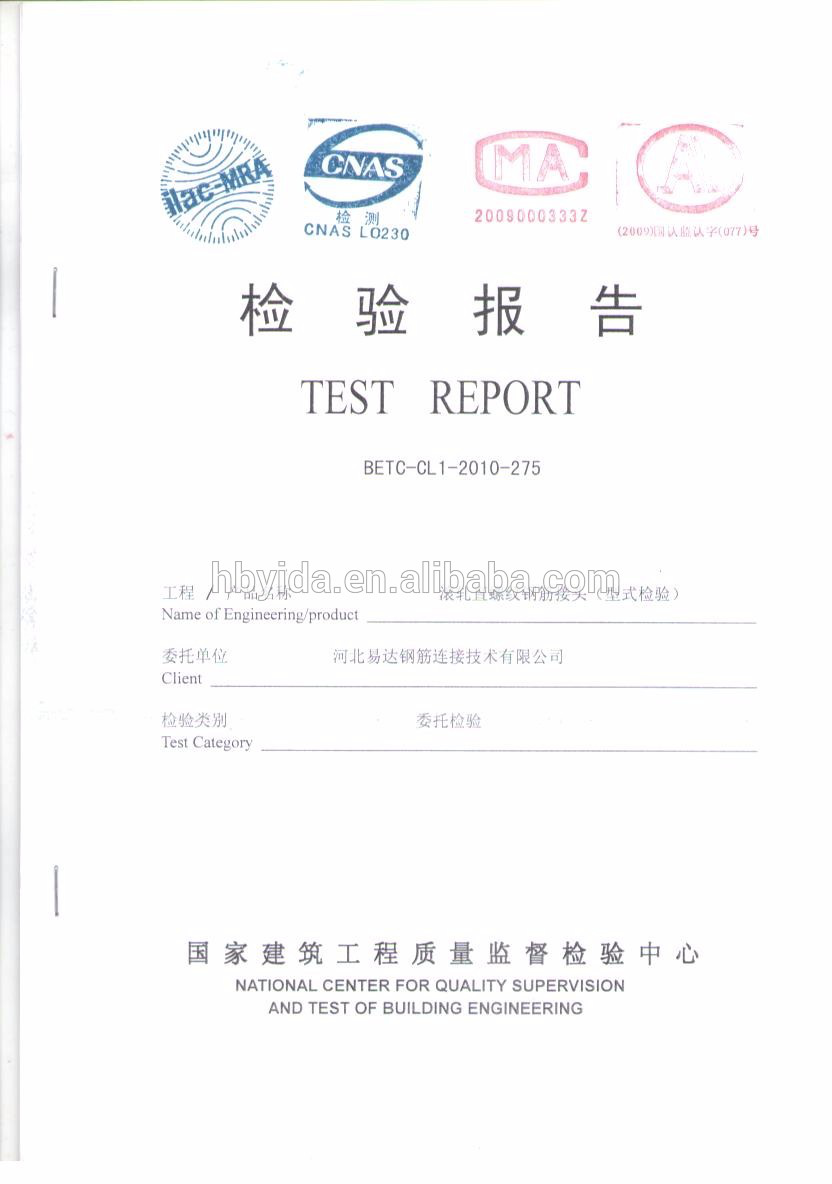

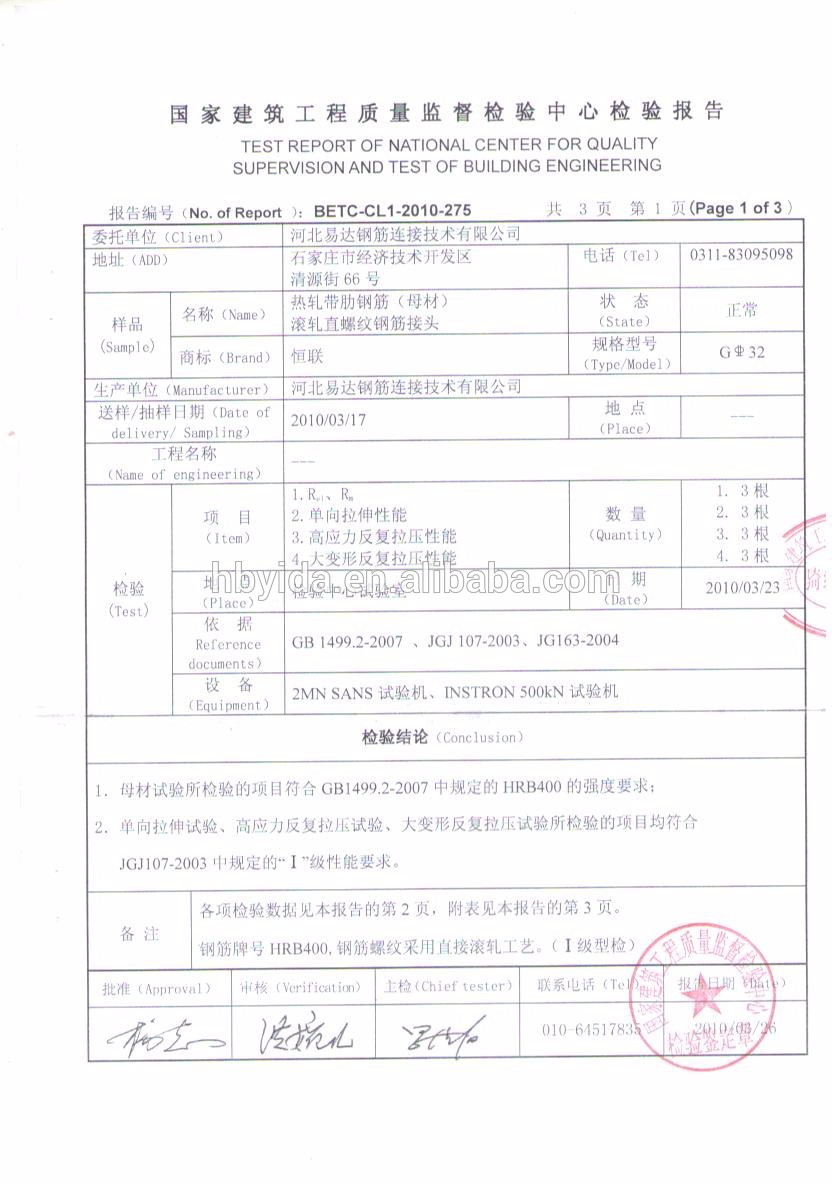

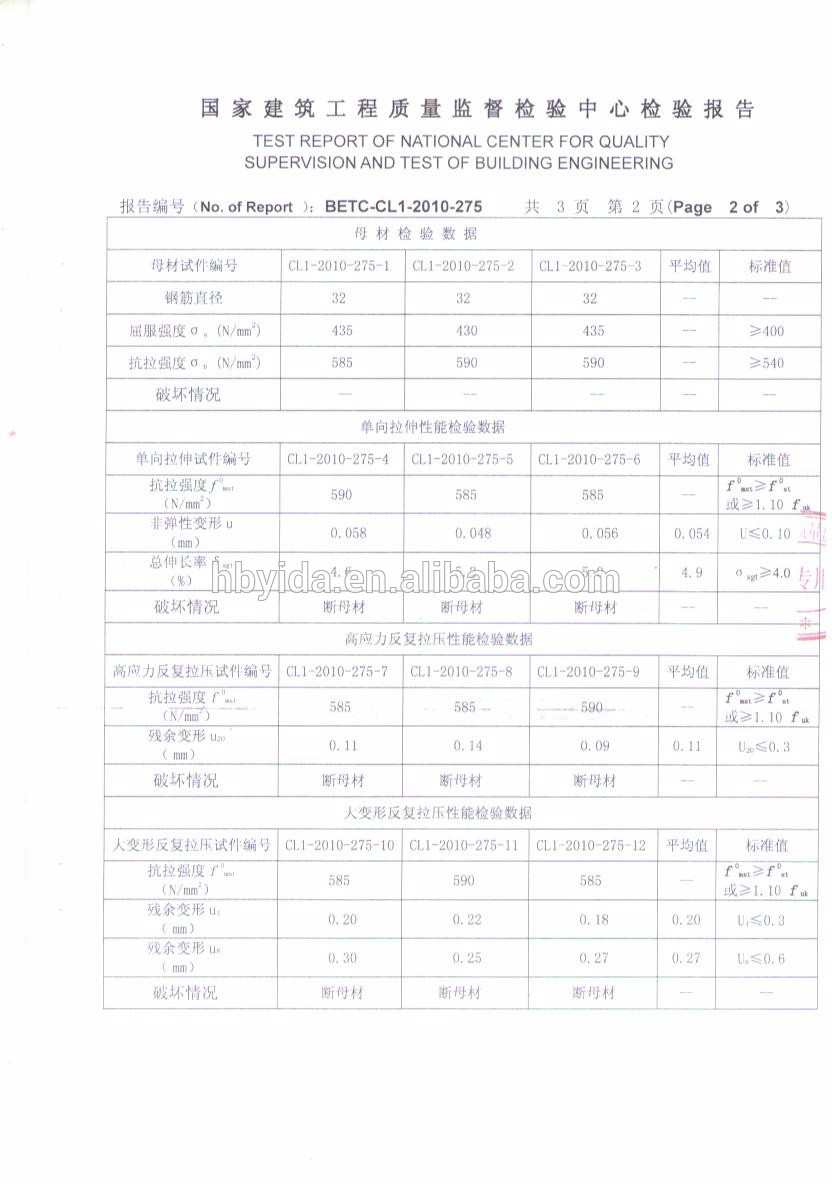

Certifications

Certifications

Our Company

Our Company

Related Products

Related Products  ACJ standard coupler

ACJ standard coupler

ACJ standard coupler is made up by two standard sleeves and one standard bolt, suitable for same diameter rebar connecting. The Yida ACJ is suitable for general application such as beams or walls where the rotation of the rebar is possible. Screw the bolt into one sleeve firstly, then rotate one rebar to screw the other bolt end into the other sleeve.

Characteristic:ACJ coupler uses standard female (sleeve) only, making rebar press more efficient as there is no need to specify different sleeves.

Application Guide:

Proper installation is very important to ensure the design load will be reached in the application. Yida strongly recommends that the installation and site quality check be done according to the required guidelines and dimensions.

●Rebar And sleeves swaged connection

Using hydraulic machine and unique split mould to swage sleeve deformation, formed the seamless connection with rebar and the swage length is to meet the standard swage length. Shorter swage length reduces the bond, while longer swage length may shorten the engagement length of the thread.

●Site installation method

Step 1:Screw the bolt into female coupler swaged with rebar, till unable to screw continually.

Step 2:Screw another side of bolt into the other sleeve after swaged with rebar, till unable to screw continually.

Step 3:With help of two pipe wrench, tighten the connection by turning both rebar / couplers in opposite direction at the same time.

Project show

Contact us Tacy Hou Tel:0311-83095058 Mob:15076193005 Skype:tacyhou

Contact us Tacy Hou Tel:0311-83095058 Mob:15076193005 Skype:tacyhou

MCJ Anchorage Terminator Coupler is made up by one standard sleeve, one standard bolt, and one standard anchorage terminator coupler,used for the connection between rebar and anchorage terminator coupler. It can be used when need using anchorage terminator coupler to connect with rebar.

Detailed Images

Detailed Images  Characteristic:MCJ Coupler is using standard sleeve, standard bolt to make the rebar connected with anchorage terminator coupler so that can satisfy the anti impact requirement.

Characteristic:MCJ Coupler is using standard sleeve, standard bolt to make the rebar connected with anchorage terminator coupler so that can satisfy the anti impact requirement. ●Rebar And sleeves swaged connection

Using hydraulic machine and unique split mould to swage sleeve deformation, formed the seamless connection with rebar and the swage length is to meet the standard swage length. Shorter swage length reduces the bond, while longer swage length may shorten the engagement length of the thread.

●Site Installation Method

Step 1:Screw the standard bolt into female coupler swaged with rebar, till unable to screw continually.

Step 2: Screw the anchorage terminator coupler into standard bolt, make the anchorage terminator coupler keep touch with female coupler.

Step 3: With help of two pipe wrench, tighten the connection by turning both two sleeves in opposite direction at the same time.

Packing & Delivery Packaging Details: Carton box with waterproof plastic bag to protect our hydraulic grip couplers,then put into wooden case of exporting use, to do the best and safe shippment of Anti impact application repair grip rebar couplers portable steel bar connectors HBYD.

Delivery Detail: Shipped in 3 days after payment

Certifications

Certifications

Our Company

Our Company

Related Products

Related Products  ACJ standard coupler

ACJ standard couplerACJ standard coupler is made up by two standard sleeves and one standard bolt, suitable for same diameter rebar connecting. The Yida ACJ is suitable for general application such as beams or walls where the rotation of the rebar is possible. Screw the bolt into one sleeve firstly, then rotate one rebar to screw the other bolt end into the other sleeve.

Characteristic:ACJ coupler uses standard female (sleeve) only, making rebar press more efficient as there is no need to specify different sleeves.

Application Guide:

Proper installation is very important to ensure the design load will be reached in the application. Yida strongly recommends that the installation and site quality check be done according to the required guidelines and dimensions.

●Rebar And sleeves swaged connection

Using hydraulic machine and unique split mould to swage sleeve deformation, formed the seamless connection with rebar and the swage length is to meet the standard swage length. Shorter swage length reduces the bond, while longer swage length may shorten the engagement length of the thread.

●Site installation method

Step 1:Screw the bolt into female coupler swaged with rebar, till unable to screw continually.

Step 2:Screw another side of bolt into the other sleeve after swaged with rebar, till unable to screw continually.

Step 3:With help of two pipe wrench, tighten the connection by turning both rebar / couplers in opposite direction at the same time.

Project show

Contact us Tacy Hou Tel:0311-83095058 Mob:15076193005 Skype:tacyhou

Contact us Tacy Hou Tel:0311-83095058 Mob:15076193005 Skype:tacyhou Related Keywords

Related Keywords