recycling waste plastic egg tray making machine

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

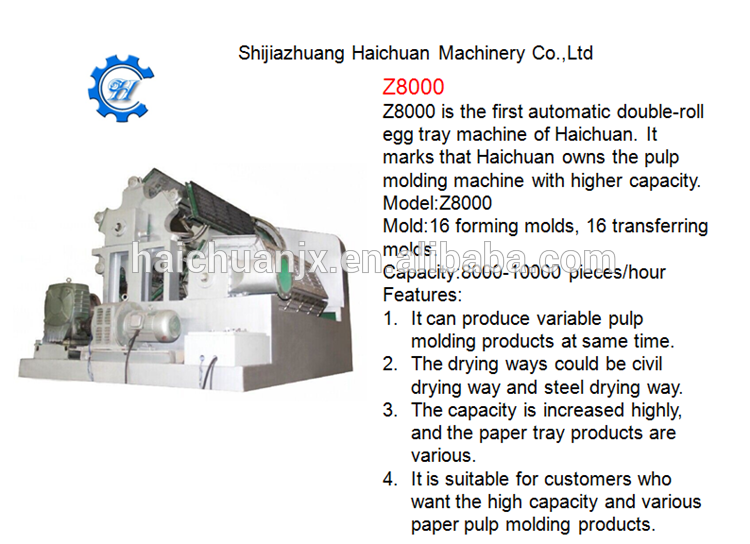

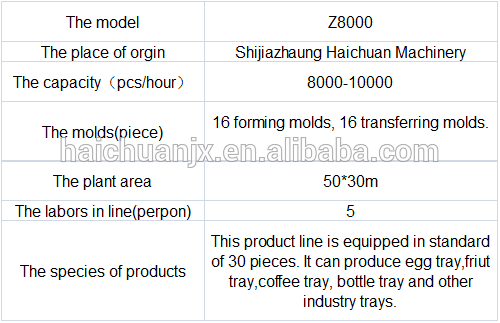

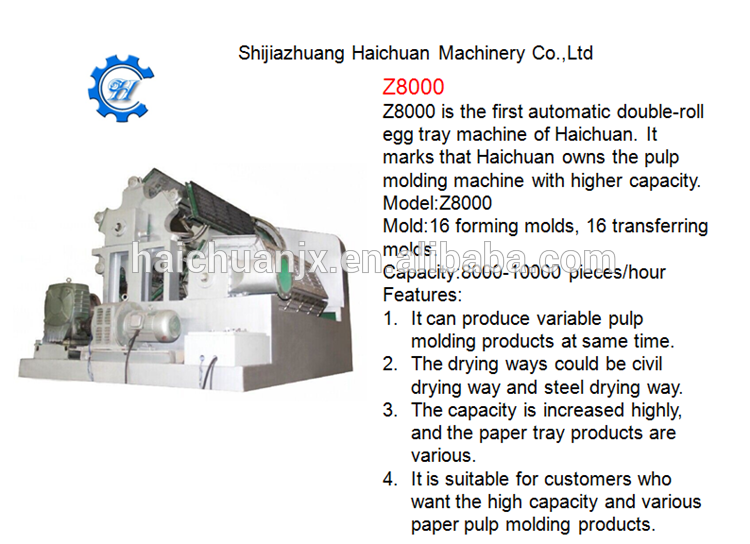

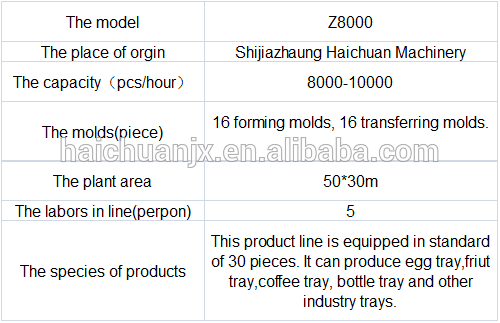

recycling waste plastic egg tray making machine Specification 1.HAICHUAN large automatic recycling egg tray making machine. 2.The capacity can reach 8000 pieces per hour. 3.This egg tray production line’ s drying way is steel multi-layers drying way. This drying way has been patented approved in China. The total consumption is 40% lower than the other factories’. 4. This egg tray machine is suitable for customers who want the higher capacity. 5. We design molds professionally. Product Description

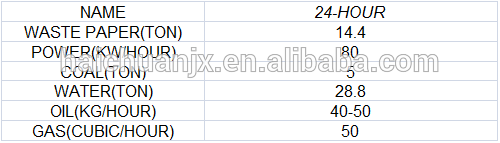

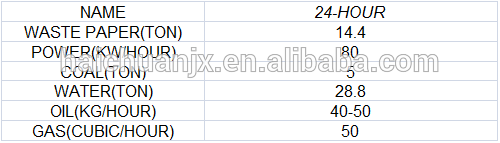

The energy consumption of Z8000 production line All of energy consumption will be different according to the practical condition.This energy consumption number is calculated via the usual line of our company.Oil and gas is used in abroad and coal is usually used in domestic as fuel.

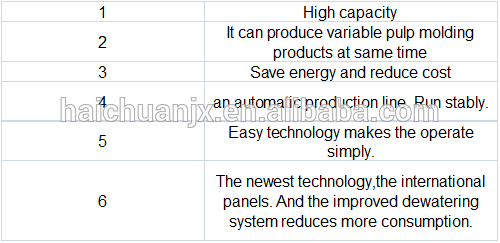

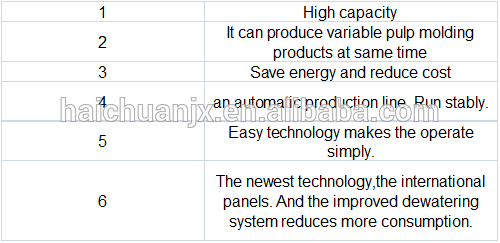

The energy consumption of Z8000 production line All of energy consumption will be different according to the practical condition.This energy consumption number is calculated via the usual line of our company.Oil and gas is used in abroad and coal is usually used in domestic as fuel.  The advantages of Z8000 egg tray production line We will introduce different production line according to different companies. We also offer free visit and study to production line. We are the only manufacturing factory in China which owns both of the egg tray producing line and egg tray machinery equipment.

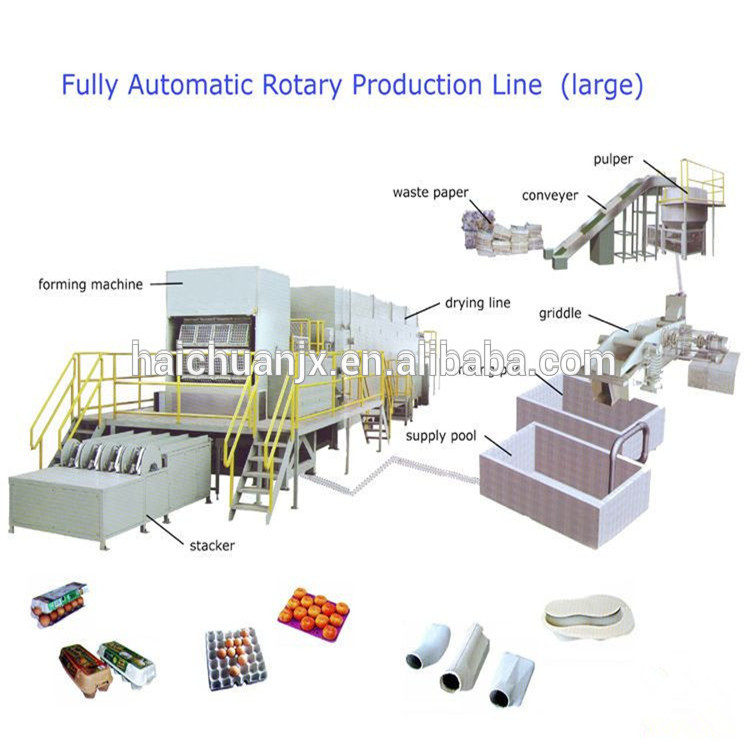

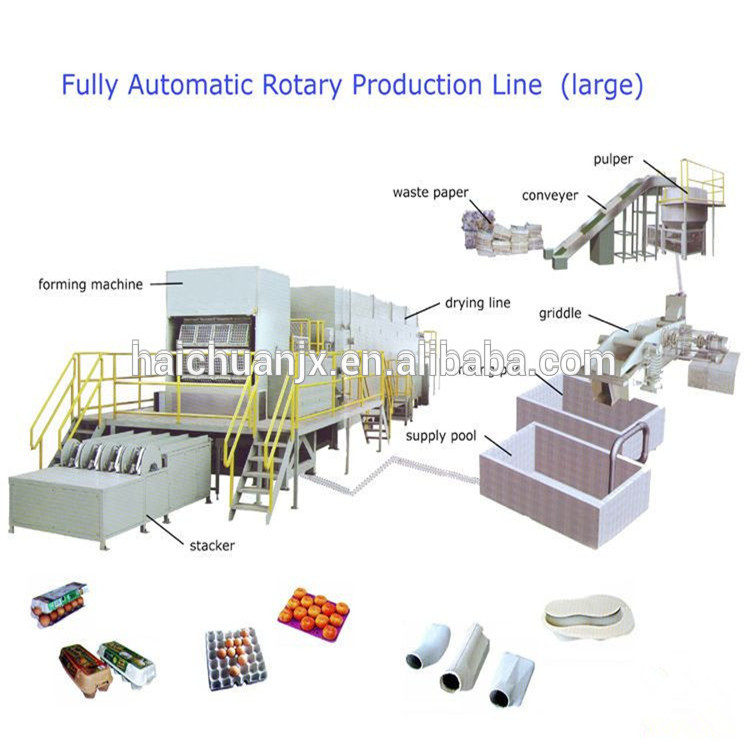

The advantages of Z8000 egg tray production line We will introduce different production line according to different companies. We also offer free visit and study to production line. We are the only manufacturing factory in China which owns both of the egg tray producing line and egg tray machinery equipment.  Production process The pulp making system we put the materials such as waste paper or magazines into hydrapulper for pulping. Then by proportioning system, we can get the proper-dense pulp applying for products. The forming system Next by adsorption molding system, paper pulp will be absorbed to molds. Then we have the dewatering processing for forming products on molds. The drying system These products dewatered will be transferred into the drying system to be dried via transferring mold .

Production process The pulp making system we put the materials such as waste paper or magazines into hydrapulper for pulping. Then by proportioning system, we can get the proper-dense pulp applying for products. The forming system Next by adsorption molding system, paper pulp will be absorbed to molds. Then we have the dewatering processing for forming products on molds. The drying system These products dewatered will be transferred into the drying system to be dried via transferring mold .  Producing details

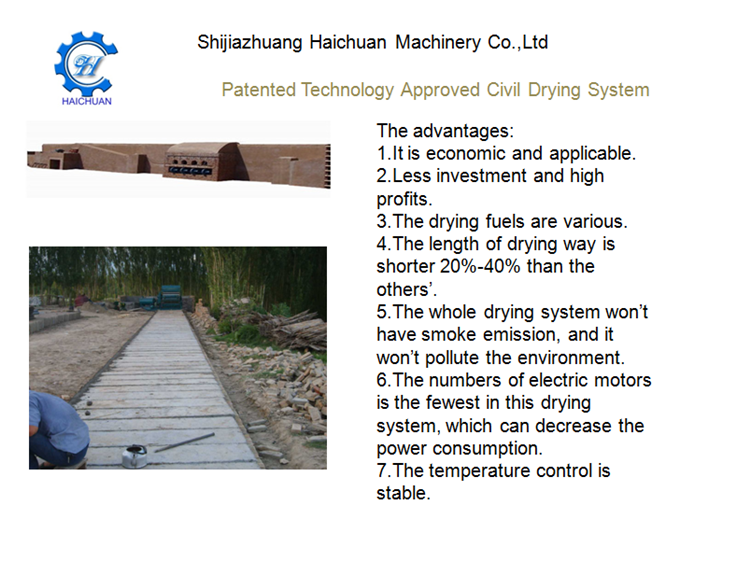

Producing details  The drying ways This egg tray production line’ s drying ways could be civil drying way and steel drying way. These two drying ways have been patented approved in China. The total consumption is 40% lower than the other factories’. It is a big step in pulp molding industry. The civil drying way

The drying ways This egg tray production line’ s drying ways could be civil drying way and steel drying way. These two drying ways have been patented approved in China. The total consumption is 40% lower than the other factories’. It is a big step in pulp molding industry. The civil drying way  The steel drying way

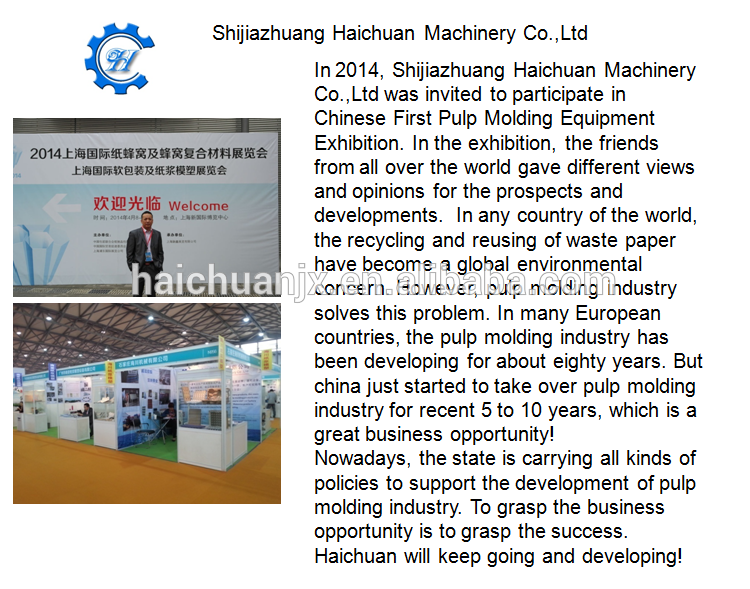

The steel drying way  The Exhibition Pulp molding industry is a typical representative of green packaging industry with features of small investment, low cost, high efficiency, and environmental protection and other advantages. Haichuan Machinery has participated in pulp molding machinery exhibitions many times, and exchanged experiences with our peers and customers from home and abroad. learning essence of this industry to produce the more energy-efficient and better- quality pulp molding machines.

The Exhibition Pulp molding industry is a typical representative of green packaging industry with features of small investment, low cost, high efficiency, and environmental protection and other advantages. Haichuan Machinery has participated in pulp molding machinery exhibitions many times, and exchanged experiences with our peers and customers from home and abroad. learning essence of this industry to produce the more energy-efficient and better- quality pulp molding machines.

Our clients! The advanced techniques and skills and over -twenties experiences of producing, assembling, debugging and training make Haichuan go aboard. Haichuan’s products are exported to Australia, India, Russian, Dominican, Malaysia, Egypt, Nigeria, Kazakhstan, Sudan, Uzbekistan and Brazil.

Our clients! The advanced techniques and skills and over -twenties experiences of producing, assembling, debugging and training make Haichuan go aboard. Haichuan’s products are exported to Australia, India, Russian, Dominican, Malaysia, Egypt, Nigeria, Kazakhstan, Sudan, Uzbekistan and Brazil.  Company Information What are the advantages of Haichuan Machinery in pulp molding industry?

Company Information What are the advantages of Haichuan Machinery in pulp molding industry?  Contact us! If you have interest in our any egg tray machine or you have any questions about us, you can contact us anytime. We are looking forward to your message!

Contact us! If you have interest in our any egg tray machine or you have any questions about us, you can contact us anytime. We are looking forward to your message!

The energy consumption of Z8000 production line All of energy consumption will be different according to the practical condition.This energy consumption number is calculated via the usual line of our company.Oil and gas is used in abroad and coal is usually used in domestic as fuel.

The energy consumption of Z8000 production line All of energy consumption will be different according to the practical condition.This energy consumption number is calculated via the usual line of our company.Oil and gas is used in abroad and coal is usually used in domestic as fuel.  The advantages of Z8000 egg tray production line We will introduce different production line according to different companies. We also offer free visit and study to production line. We are the only manufacturing factory in China which owns both of the egg tray producing line and egg tray machinery equipment.

The advantages of Z8000 egg tray production line We will introduce different production line according to different companies. We also offer free visit and study to production line. We are the only manufacturing factory in China which owns both of the egg tray producing line and egg tray machinery equipment.  Production process The pulp making system we put the materials such as waste paper or magazines into hydrapulper for pulping. Then by proportioning system, we can get the proper-dense pulp applying for products. The forming system Next by adsorption molding system, paper pulp will be absorbed to molds. Then we have the dewatering processing for forming products on molds. The drying system These products dewatered will be transferred into the drying system to be dried via transferring mold .

Production process The pulp making system we put the materials such as waste paper or magazines into hydrapulper for pulping. Then by proportioning system, we can get the proper-dense pulp applying for products. The forming system Next by adsorption molding system, paper pulp will be absorbed to molds. Then we have the dewatering processing for forming products on molds. The drying system These products dewatered will be transferred into the drying system to be dried via transferring mold .  Producing details

Producing details  The drying ways This egg tray production line’ s drying ways could be civil drying way and steel drying way. These two drying ways have been patented approved in China. The total consumption is 40% lower than the other factories’. It is a big step in pulp molding industry. The civil drying way

The drying ways This egg tray production line’ s drying ways could be civil drying way and steel drying way. These two drying ways have been patented approved in China. The total consumption is 40% lower than the other factories’. It is a big step in pulp molding industry. The civil drying way  The steel drying way

The steel drying way  The Exhibition Pulp molding industry is a typical representative of green packaging industry with features of small investment, low cost, high efficiency, and environmental protection and other advantages. Haichuan Machinery has participated in pulp molding machinery exhibitions many times, and exchanged experiences with our peers and customers from home and abroad. learning essence of this industry to produce the more energy-efficient and better- quality pulp molding machines.

The Exhibition Pulp molding industry is a typical representative of green packaging industry with features of small investment, low cost, high efficiency, and environmental protection and other advantages. Haichuan Machinery has participated in pulp molding machinery exhibitions many times, and exchanged experiences with our peers and customers from home and abroad. learning essence of this industry to produce the more energy-efficient and better- quality pulp molding machines.

Our clients! The advanced techniques and skills and over -twenties experiences of producing, assembling, debugging and training make Haichuan go aboard. Haichuan’s products are exported to Australia, India, Russian, Dominican, Malaysia, Egypt, Nigeria, Kazakhstan, Sudan, Uzbekistan and Brazil.

Our clients! The advanced techniques and skills and over -twenties experiences of producing, assembling, debugging and training make Haichuan go aboard. Haichuan’s products are exported to Australia, India, Russian, Dominican, Malaysia, Egypt, Nigeria, Kazakhstan, Sudan, Uzbekistan and Brazil.  Company Information What are the advantages of Haichuan Machinery in pulp molding industry?

Company Information What are the advantages of Haichuan Machinery in pulp molding industry?  Contact us! If you have interest in our any egg tray machine or you have any questions about us, you can contact us anytime. We are looking forward to your message!

Contact us! If you have interest in our any egg tray machine or you have any questions about us, you can contact us anytime. We are looking forward to your message!

Related Keywords

Related Keywords