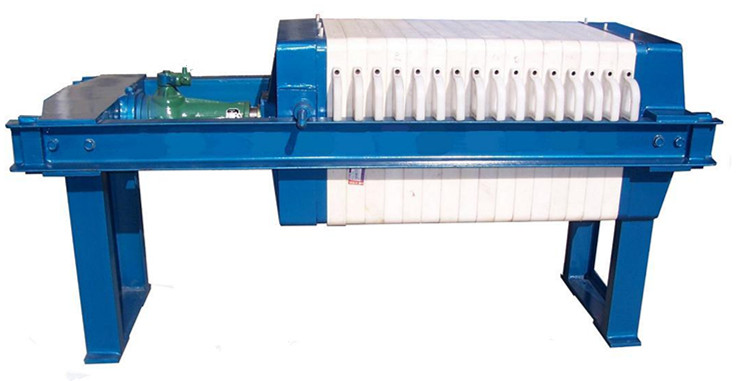

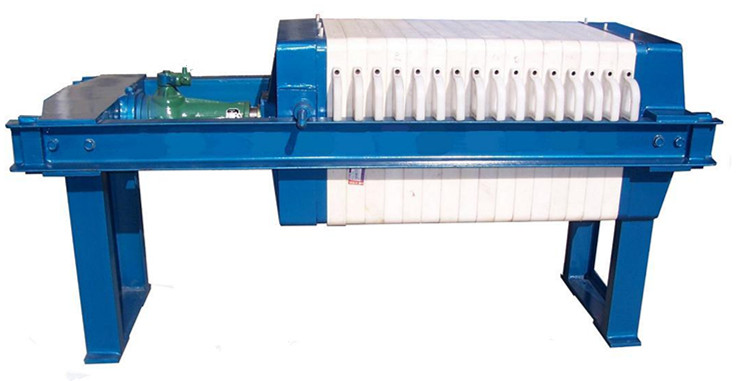

Manual Chamber Filter Press

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Specifications Price is reason

Simple operation

Small room

Manual filter press Jack pressed filter adopts screw jack as clamping device with features of simple structure, easy to operate, easy maintenance, no-power, economical and practical, and wide application. Jack pressed filter is the ideal equipment for solid-liquid separation. 1. Man rotates the Jack, and the Jack pushes the screw shaft, pressing filter plates to form sealed chambers. It could prevent the slurry from spurting and leakage when sending the slurry with pressure. 2. The slurry is sent to each sealed filter chamber by the feeding pump with pressure, going into filter plates and filter cloths. The clean water will be filtered out from the filter plate water outlet by the filter cloth, but the solid is kept in the chambers Structure of filter press:

1. Machine frame: include Thrust plate, Pressure strip and girder. 2. Pressing units: manual pressing 3. Filtering unites: filter plate, filter frame, filter cloth. Usuage: extensively used in solid&liquid separation areas,such as petroleum, chemical industry, metallurgy, medicine, coal and sewage process and other industries. Product Description

Simple operation

Small room

Manual filter press Jack pressed filter adopts screw jack as clamping device with features of simple structure, easy to operate, easy maintenance, no-power, economical and practical, and wide application. Jack pressed filter is the ideal equipment for solid-liquid separation. 1. Man rotates the Jack, and the Jack pushes the screw shaft, pressing filter plates to form sealed chambers. It could prevent the slurry from spurting and leakage when sending the slurry with pressure. 2. The slurry is sent to each sealed filter chamber by the feeding pump with pressure, going into filter plates and filter cloths. The clean water will be filtered out from the filter plate water outlet by the filter cloth, but the solid is kept in the chambers Structure of filter press:

1. Machine frame: include Thrust plate, Pressure strip and girder. 2. Pressing units: manual pressing 3. Filtering unites: filter plate, filter frame, filter cloth. Usuage: extensively used in solid&liquid separation areas,such as petroleum, chemical industry, metallurgy, medicine, coal and sewage process and other industries. Product Description

| 450 PP chamber filter press(manual machanical) | ||||||||||

| Model | Filter area (sqm) | Chamber capacity(L) | Plate thickness(mm) | Plate number(pc) | Chamber number(pc) | Filter cake thickness (mm) | Dimension LxWxH(mm) | Working pressure in chamber(Mpa) | Power(kw) | Weight (kg) |

| 2 | 20 | 45 | 4 | 5 | 30 | 1720x500x880 | 0.6 0.8 1.2 | 1.5 | 270 | |

| 4 | 40 | 45 | 9 | 10 | 30 | 1940x500x880 | 1.5 | 340 | ||

| 6 | 60 | 45 | 14 | 15 | 30 | 2170x500x880 | 1.5 | 410 | ||

| 8 | 80 | 45 | 19 | 20 | 30 | 2395x500x880 | 1.5 | 400 | ||

| 10 | 100 | 45 | 24 | 25 | 30 | 2620x500x880 | 1.5 | 550 | ||

| 12 | 120 | 45 | 29 | 30 | 30 | 2845x500x880 | 1.5 | 620 | ||

Related Keywords

Related Keywords