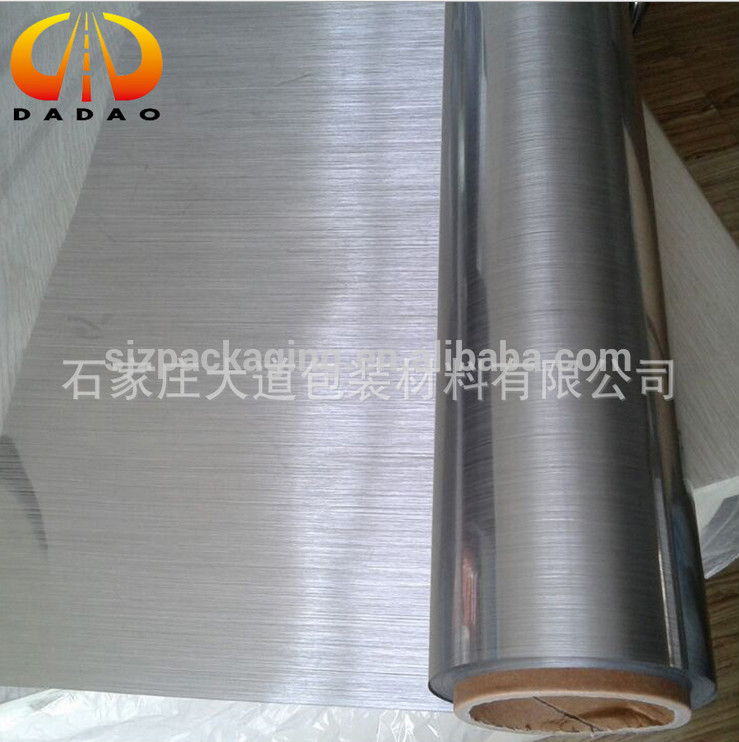

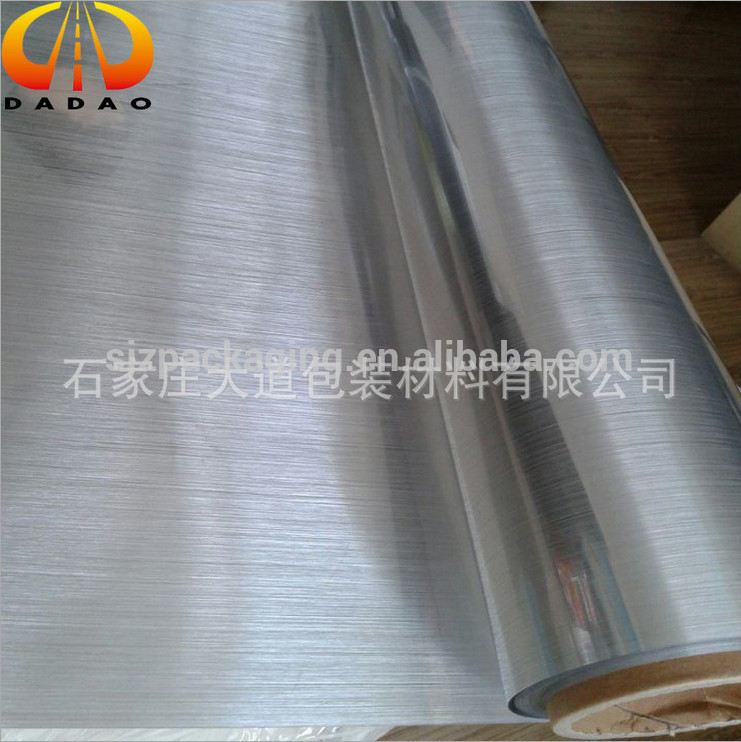

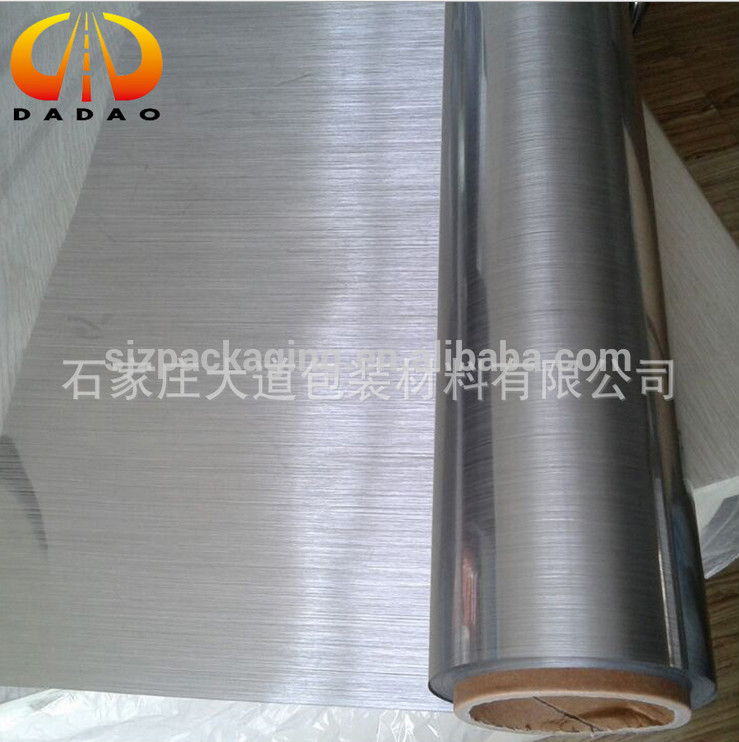

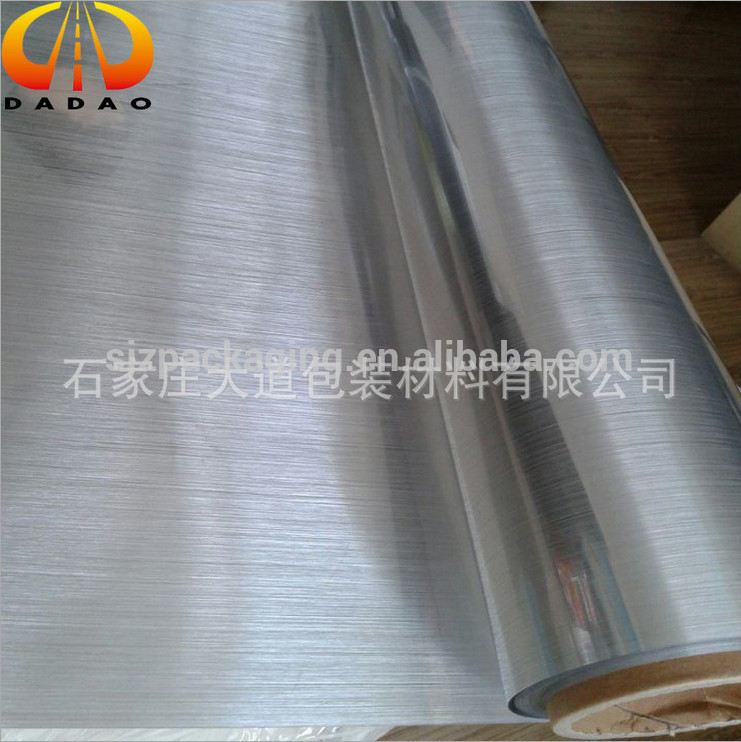

Wire Drawing Brushed VMPET film for refrigerator panel

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Wire Drawing Brushed VMPET film for refrigerator panel Product Description Substrate material: PET film Thickness: 8 micron, 10, 12, 15, 23,36,100,125,150,175 micron etc Max Width : 2500mm Other spec can be customized according to your requirement. Processing method: vacuum metalized Color : Silver, Gold, Matte Silver, Matte Gold Applications:packaging film, lamination film, water resistant barrier, reflective film. Features: 1) High strength 2) Good printability 3) Good barrier performance 4) Low oxygen permeability 5) Non-splash aluminum, wrinkle-free, no tramlines or smears 6) wide application range Application: 1.Packaging & Decorative Grade Film: Face-Stock for self-adhesive, Gift-Wrapping, Glitter Powder, Metallic Yarn, Food-Packing, Laminated Paper/Paper board, Holographic Embossing. 2 Reflective film For reflect the sunshine and make the best use of sunshine 3.Optical Grade Film : Reflector in Liquid Crystal Display, LCD`s backlight unit, Light-Shielding. 4.Other Grade Film : Cables Wrapping, Motors, Hot Stamping Foil, Transfer Printing, Release Agent, Leader Tape, OHP, Sheeting Protectors, Silicone Coating, Adhesive Tape, Solar Control Film. Technical date sheet

Product show:

Our certificate

Our certificate  Contact information: SHIJIAZHUANG DADAO PACKAGING MATERIALS CO.,LTD ADD:NO 9 Changjiang Road ,High Technology Industrial Development Zone,Shijiahzuang Contact person: Rita Cao Mob:86-15530115611 Tel: 008631185830672/435 Fax: 008631185381038 Email:Rita @ddpackaging. Skype:caoyuan361

Contact information: SHIJIAZHUANG DADAO PACKAGING MATERIALS CO.,LTD ADD:NO 9 Changjiang Road ,High Technology Industrial Development Zone,Shijiahzuang Contact person: Rita Cao Mob:86-15530115611 Tel: 008631185830672/435 Fax: 008631185381038 Email:Rita @ddpackaging. Skype:caoyuan361

Deep Drawing film | ||||

Properties | Units | Typical Values | Test Methods | |

|

Thickness | μm | 12 | DIN53370 | |

Tensile Strength | MD | MPa | 218 | DIN53455-6-5 |

TD | 231 | |||

Elongation at Break | MD | % | 111 | DIN53455-6-5 |

TD | 114 | |||

Coefficient of Friction | F/F-μs | - | 0.48 | DIN53375 |

F/F-μk | 0.48 | |||

Heat Shrinkage | MD | % | 2.0 | BMSTT11 |

TD | 0.8 | |||

|

Thickness of Aluminum Layer | Ω/ | 2.0 | Resistance Tester | |

|

Optical Density | OD | 2.0 | MACBETH TD904 | |

Adhesion of Aluminum Layer | % | 100 | 3M Gummed Tape | |

Tolerace of Aluminum Layer | % | 6 | Resistance Tester | |

|

Gloss | % | 132.6 | ASTM D2457 | |

|

Surface tension | Dyne/cm | 60 | ASTM D2578 | |

Our certificate

Our certificate  Contact information: SHIJIAZHUANG DADAO PACKAGING MATERIALS CO.,LTD ADD:NO 9 Changjiang Road ,High Technology Industrial Development Zone,Shijiahzuang Contact person: Rita Cao Mob:86-15530115611 Tel: 008631185830672/435 Fax: 008631185381038 Email:Rita @ddpackaging. Skype:caoyuan361

Contact information: SHIJIAZHUANG DADAO PACKAGING MATERIALS CO.,LTD ADD:NO 9 Changjiang Road ,High Technology Industrial Development Zone,Shijiahzuang Contact person: Rita Cao Mob:86-15530115611 Tel: 008631185830672/435 Fax: 008631185381038 Email:Rita @ddpackaging. Skype:caoyuan361 Related Keywords

Related Keywords