KT-1.2 sunflower seed dehulling machine

- Delivery Time:

- 60 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

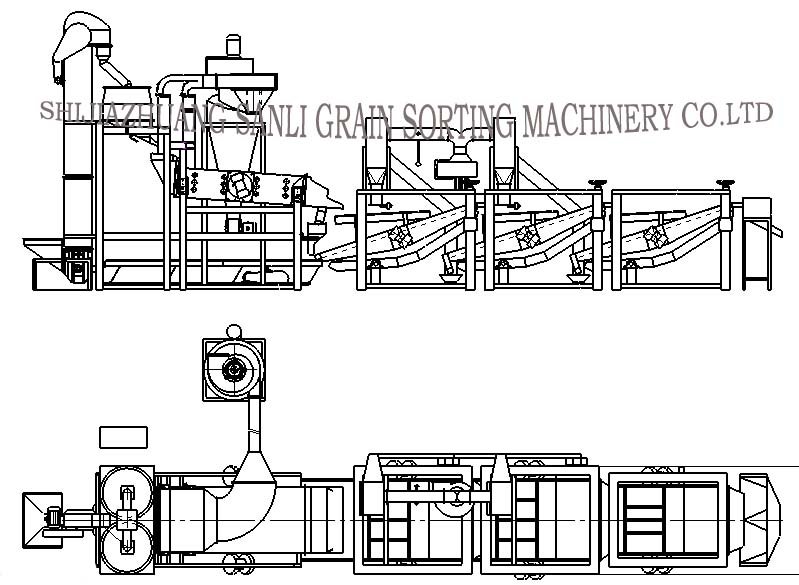

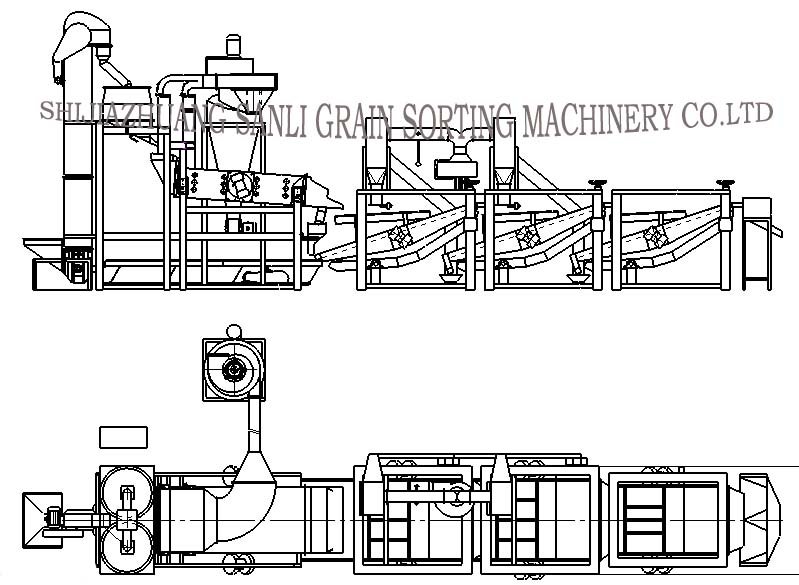

Specifications KT-1.2 KT-1.2 sunflower seed dehulling machine

Productivity :8-12T/day

Delivery time: 60days

Minimum order quantity: 1set

KT-1.2 Sunflower seed dehulling machine Brief Introduction: KT-1200 series sunflower seed hulling line are our company's patented products. The equipment can achieve many functions, such as cleaning, de-hulling, removing shells, separating, re-separating, etc. The unhulled seeds will be returned to the huller for re-hulling again automatically, thus automation degree has been greatly improved. The equipment features compact structure, minimum space occupation, low damage of seeds and kernels, automatic feeding of unhulled seeds, easy operation and maintenance. It is well recognized to be one of the most optimum equipment for sunflower seeds cleaning, hulling and separating for both bakery kernels and confectionery kernels for kernel industry and oil industry in the world. Technical specification

Productivity :8-12T/day

Delivery time: 60days

Minimum order quantity: 1set

KT-1.2 Sunflower seed dehulling machine Brief Introduction: KT-1200 series sunflower seed hulling line are our company's patented products. The equipment can achieve many functions, such as cleaning, de-hulling, removing shells, separating, re-separating, etc. The unhulled seeds will be returned to the huller for re-hulling again automatically, thus automation degree has been greatly improved. The equipment features compact structure, minimum space occupation, low damage of seeds and kernels, automatic feeding of unhulled seeds, easy operation and maintenance. It is well recognized to be one of the most optimum equipment for sunflower seeds cleaning, hulling and separating for both bakery kernels and confectionery kernels for kernel industry and oil industry in the world. Technical specification

| Model | Productivity | Size(L×W×H) | Unbroken Kernel | Unhulled rate |

| KT-1.2A | 6-8 T/Day | 11000×2500×4200mm | ≥92% | ≤3% |

| KT-1.2B | 8-10 T/Day | 13000×2500×4200mm | ≥92% | ≤3% |

Related Keywords

Related Keywords