Stainless Steel Bolting Cloth

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Stainless Steel Bolting Cloth · cloth thickness maintained +/- 1.5 micron · low elongation reduces tension loss and gives improved registration · increased mesh strength extends screen life and allows faster run speeds · faster tension stabilisation improves screen turnaround time · production technique ensures mesh lays flat for easier handling We can produce from 1 to 636 Stainless Steel bolting cloth.

1.Stainless Steel bolting cloth weave types:Four shaft plain weave ,twill weave, Bead knitting pattern,dutch weave,five shaft twill weave.

2.Stainless Steel bolting cloth performance:excellent resistance against acid, alkali, heat and corrosion,long time use,Magnetic,Conductive.

3.Stainless Steel Wire Mesh application:For acid and alkali environmental conditions screening and filtering. Slurry net in petroleum industry, chemical fiber industry as sieve mesh, electroplate industry to make pickling mesh Also uses in filter of oils, chemicals, food, pharmaceuticals, also sifting and sieving of solid, liquid and gas in mine, metallurgy, airspace, machine making, etc Stringent quality control procedures are applied through each stage of the manufacturing process, from specifying and verifying the tolerances and mechanical properties of the wire, through to the final inspection of the finished mesh. All materials are 100% inspected and individual apertures are checked using shadow graph analysis

1.Stainless Steel bolting cloth weave types:Four shaft plain weave ,twill weave, Bead knitting pattern,dutch weave,five shaft twill weave.

2.Stainless Steel bolting cloth performance:excellent resistance against acid, alkali, heat and corrosion,long time use,Magnetic,Conductive.

3.Stainless Steel Wire Mesh application:For acid and alkali environmental conditions screening and filtering. Slurry net in petroleum industry, chemical fiber industry as sieve mesh, electroplate industry to make pickling mesh Also uses in filter of oils, chemicals, food, pharmaceuticals, also sifting and sieving of solid, liquid and gas in mine, metallurgy, airspace, machine making, etc Stringent quality control procedures are applied through each stage of the manufacturing process, from specifying and verifying the tolerances and mechanical properties of the wire, through to the final inspection of the finished mesh. All materials are 100% inspected and individual apertures are checked using shadow graph analysis

material |

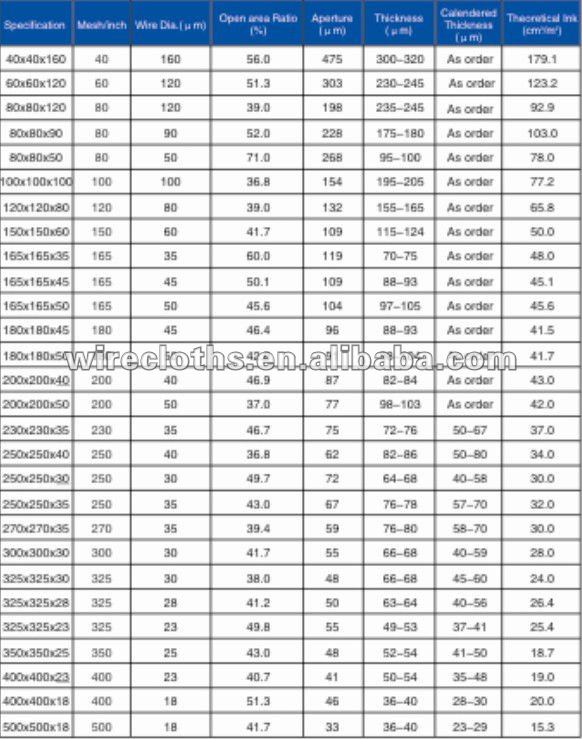

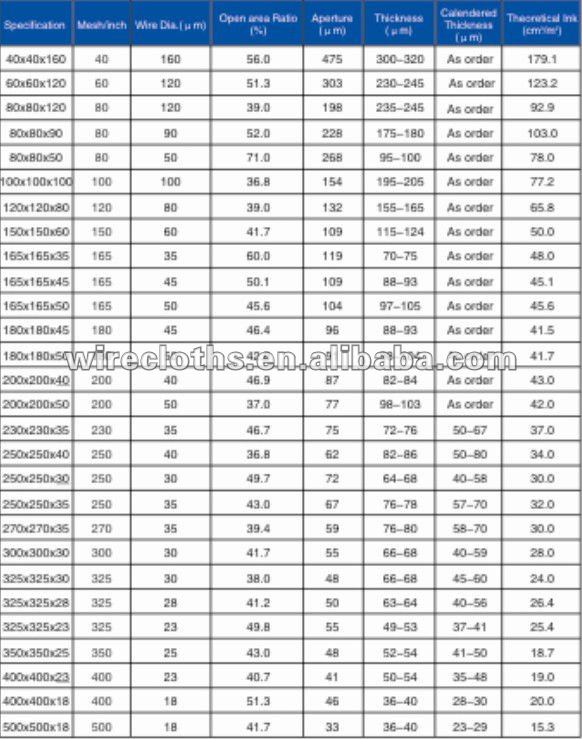

Mesh/inch | wire (mm) | Openging% | Aperture (micron) | thickness (micron) | one time calender thickness(micron) | two time calender thickness (µm) | width(cm) | Ink thickness (cm3/m2) | Suggestion tension (N/CM) |

304N | 200 | 0.04 | 46.9 | 87 | 81-82 | 66-68 | 62-64 | 100 | 43.0 | 45-48 |

304N | 200 | 0.04 | 46.9 | 87 | 81-82 | 66-68 | 62-64 | 122 | 43.0 | 45-48 |

304N | 250 | 0.03 | 49.7 | 72 | 64-65 | 49 | 45 | 100 | 30.0 | 40-45 |

304N | 250 | 0.03 | 49.7 | 72 | 64-65 | 49 | 45 | 122 | 30.0 | 40-45 |

304N | 250 | 0.035 | 43.0 | 67 | 72-73 | 58 | 54 | 100 | 32.0 | 42-45 |

304N | 300 | 0.03 | 41.7 | 55 | 66-68 | 51 | 47 | 100 | 28.0 | 40-45 |

304N | 325 | 0.028 | 41.2 | 50 | 63-64 | 49 | 45 | 100 | 26.4 | 40-42 |

304N | 325 | 0.028 | 41.2 | 50 | 63-64 | 49 | 45 | 122 | 26.4 | 40-42 |

304N | 325 | 0.023 | 49.8 | 55 | 50-51 | 38 | 35 | 122 | 25.4 | 40-42 |

Related Keywords

Related Keywords

You May Also Like

You May Also Like