Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

- Delivery Time:

- 3 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump  Pump Description

Pump Description  Overview for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump AMAH series heavy duty slurry pumps are end-suction, split-case, centrifugal slurry pumps provide excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost AMAH Slurry Pump have advanctages of with reasonable construction, reliable operation, long service life. It is widely used in transporting abrasive and corrosive slurry in mining, metallurgy, electric power, coal, chemicals, building etc. Especially well accepted by coal & chrome washing plant, mineral processing plant, power plant etc. The Max Capacity: 5000m3/h The highest pressure for single stage pump: 100m

Overview for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump AMAH series heavy duty slurry pumps are end-suction, split-case, centrifugal slurry pumps provide excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost AMAH Slurry Pump have advanctages of with reasonable construction, reliable operation, long service life. It is widely used in transporting abrasive and corrosive slurry in mining, metallurgy, electric power, coal, chemicals, building etc. Especially well accepted by coal & chrome washing plant, mineral processing plant, power plant etc. The Max Capacity: 5000m3/h The highest pressure for single stage pump: 100m  Working conditions for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

Working conditions for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

Parameter

Parameter  Performance for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

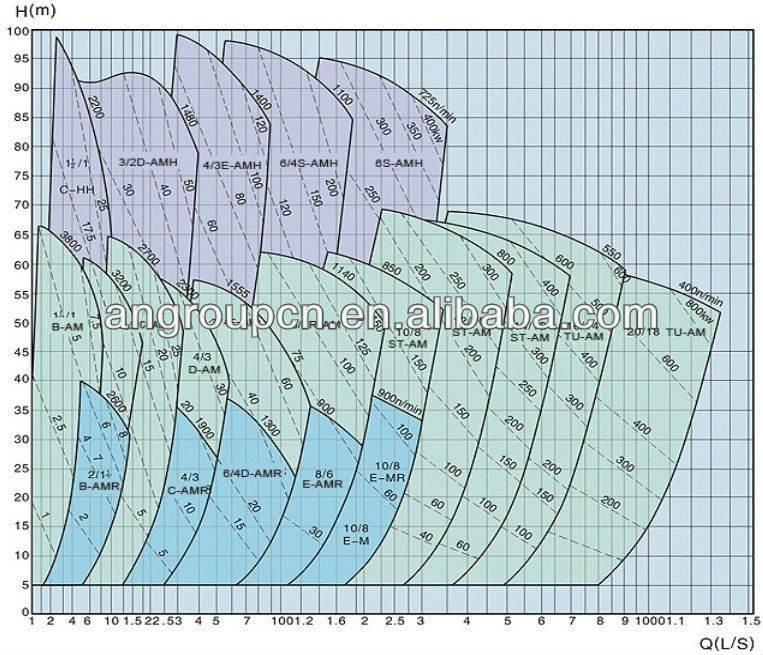

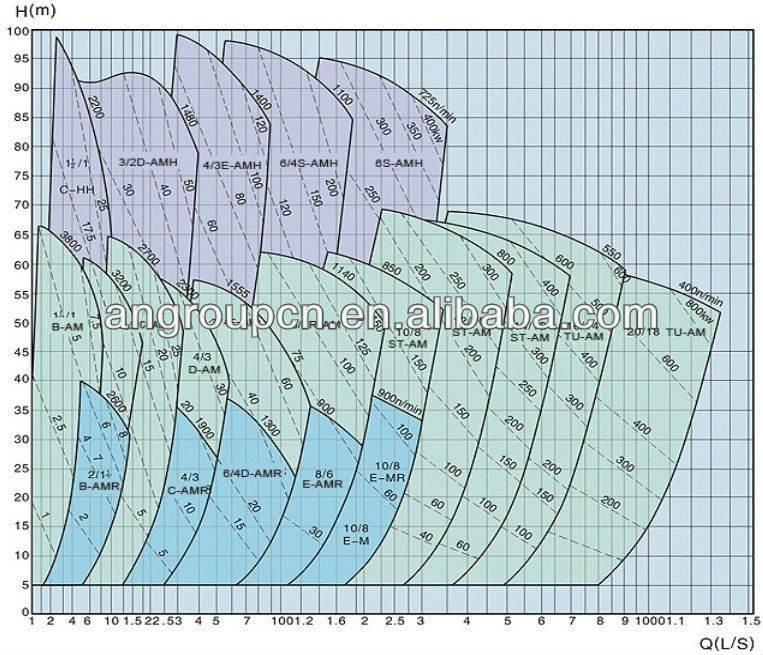

Performance for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump  Main Parameter for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump The pump have a wide performance range, good cavitation performance and high efficiency.

Main Parameter for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump The pump have a wide performance range, good cavitation performance and high efficiency.

Specification:

Capacity (m3/h):5000m3/h

Head (m):90m

Speed (r/min):800-3000

Max. Efficiency %:90

NPSH (m): 3-5 Model Meanings for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump Model 6x4E-AMR

6x4: Inlet x outlet diamater(mm)

E: Bearing housing frame type

AM: Series model for slurry pump

R: Rubber lined material Construction Drawing Construction of Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

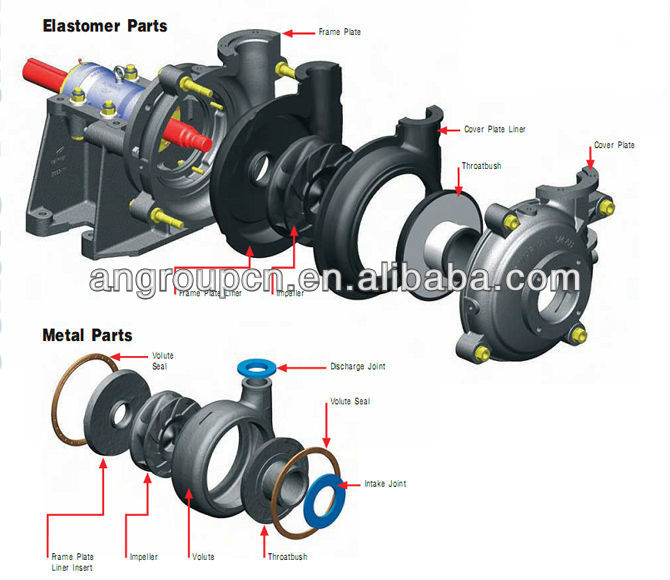

Construction of Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump  Construction Features for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

Construction Features for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

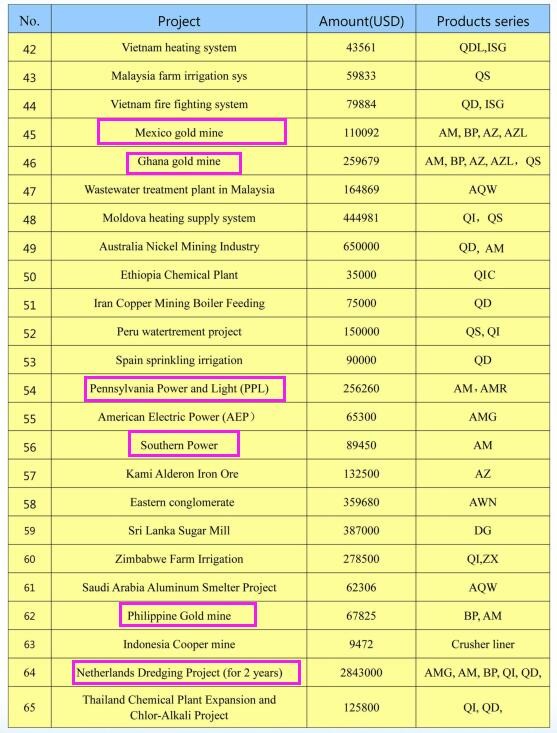

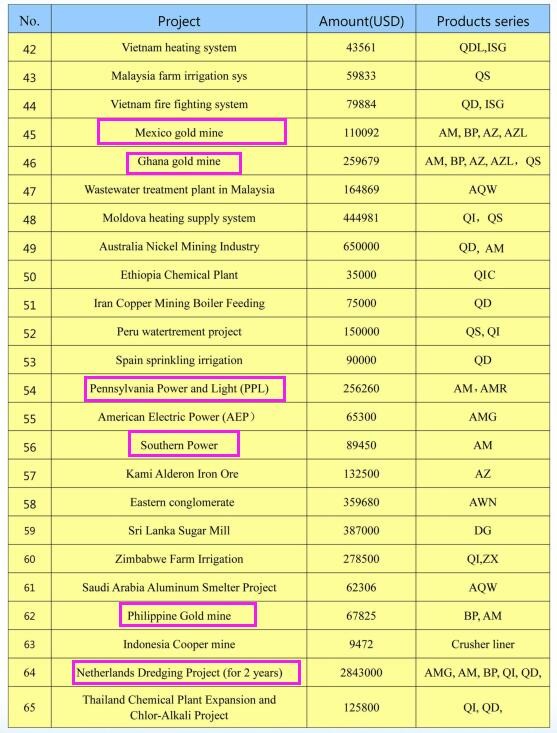

Cooperated Clients  Cooperated Client for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump Below is part of our customers list, just for refrence:

Cooperated Client for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump Below is part of our customers list, just for refrence:  AN PUMP History

AN PUMP History

Certifications

Certifications  Certification for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

Certification for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump  Contact AN PUMP

Contact AN PUMP  Ailen Sales Engineer Dept. E: ailen(@)angroupcn.com SJZ An Pump Machinery Co., Ltd www.angroupcn.com | www.heavydutypump.com |www.pumplinks.com M: 0086-152-0311-6877(WhatsApp) T: 0086-311-8994-0549 F: 0086-311-8627-1170 Skype: ailenflypeng WeChat: AilenPeng GTalk: ailencpeng(@)gmail.com

Ailen Sales Engineer Dept. E: ailen(@)angroupcn.com SJZ An Pump Machinery Co., Ltd www.angroupcn.com | www.heavydutypump.com |www.pumplinks.com M: 0086-152-0311-6877(WhatsApp) T: 0086-311-8994-0549 F: 0086-311-8627-1170 Skype: ailenflypeng WeChat: AilenPeng GTalk: ailencpeng(@)gmail.com

Pump Description

Pump Description  Overview for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump AMAH series heavy duty slurry pumps are end-suction, split-case, centrifugal slurry pumps provide excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost AMAH Slurry Pump have advanctages of with reasonable construction, reliable operation, long service life. It is widely used in transporting abrasive and corrosive slurry in mining, metallurgy, electric power, coal, chemicals, building etc. Especially well accepted by coal & chrome washing plant, mineral processing plant, power plant etc. The Max Capacity: 5000m3/h The highest pressure for single stage pump: 100m

Overview for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump AMAH series heavy duty slurry pumps are end-suction, split-case, centrifugal slurry pumps provide excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost AMAH Slurry Pump have advanctages of with reasonable construction, reliable operation, long service life. It is widely used in transporting abrasive and corrosive slurry in mining, metallurgy, electric power, coal, chemicals, building etc. Especially well accepted by coal & chrome washing plant, mineral processing plant, power plant etc. The Max Capacity: 5000m3/h The highest pressure for single stage pump: 100m  Working conditions for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

Working conditions for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump | Mineral Processing | Mill Grinding | Chemical Slurry Service | Food Processing |

| Cyclone Feeds | Pulp and Paper | Ash Handling | Cyclone feed |

| Flotation | Coal washery | Power plant | Iron Ore Dressing Plant |

| Potash Fertilizer Plant | Alumina Industry | Sand Excavation | Mineral Concentration Plant |

Parameter

Parameter  Performance for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

Performance for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump  Main Parameter for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump The pump have a wide performance range, good cavitation performance and high efficiency.

Main Parameter for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump The pump have a wide performance range, good cavitation performance and high efficiency.Specification:

Capacity (m3/h):5000m3/h

Head (m):90m

Speed (r/min):800-3000

Max. Efficiency %:90

NPSH (m): 3-5 Model Meanings for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump Model 6x4E-AMR

6x4: Inlet x outlet diamater(mm)

E: Bearing housing frame type

AM: Series model for slurry pump

R: Rubber lined material Construction Drawing

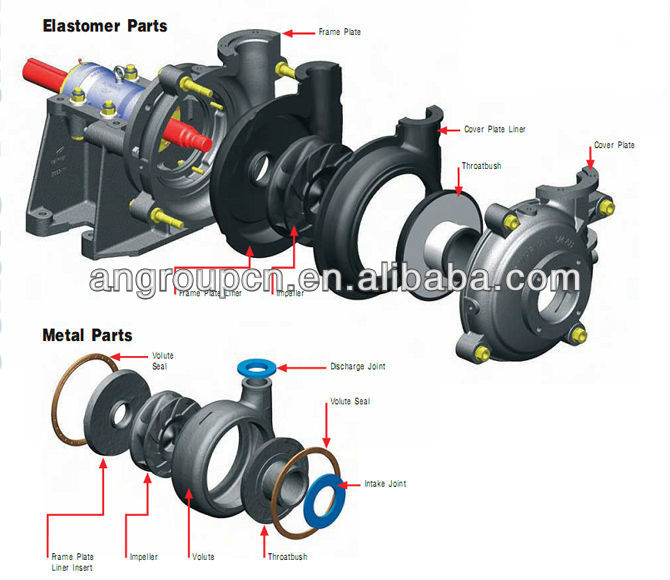

Construction of Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

Construction of Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump  Construction Features for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

Construction Features for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump | Liners | Wide variety of metallurgic and elastomeric options (metal and elastomer interchangeable); |

| Impeller | Hard metal and molded elastomer impellers are completely interchangeable. Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. |

| Casing | Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety. |

| Shaft | With large shaft diameters, heavy duty bearing assemblies and robust slurry pumping capacity, AN PUMP slurry pumps provide a cost-effective and ideal alternative to longer lead times and engineering services that are often costly or not available elsewhere. |

Cooperated Client for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump Below is part of our customers list, just for refrence:

Cooperated Client for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump Below is part of our customers list, just for refrence:  AN PUMP History

AN PUMP History

Certifications

Certifications  Certification for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump

Certification for Long Service Life Energy Saving Hydraulic Full Flow Slurry Pump  Contact AN PUMP

Contact AN PUMP  Ailen Sales Engineer Dept. E: ailen(@)angroupcn.com SJZ An Pump Machinery Co., Ltd www.angroupcn.com | www.heavydutypump.com |www.pumplinks.com M: 0086-152-0311-6877(WhatsApp) T: 0086-311-8994-0549 F: 0086-311-8627-1170 Skype: ailenflypeng WeChat: AilenPeng GTalk: ailencpeng(@)gmail.com

Ailen Sales Engineer Dept. E: ailen(@)angroupcn.com SJZ An Pump Machinery Co., Ltd www.angroupcn.com | www.heavydutypump.com |www.pumplinks.com M: 0086-152-0311-6877(WhatsApp) T: 0086-311-8994-0549 F: 0086-311-8627-1170 Skype: ailenflypeng WeChat: AilenPeng GTalk: ailencpeng(@)gmail.com Related Keywords

Related Keywords