Multistage Pump Structure and Water Usage centrifugal pump

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

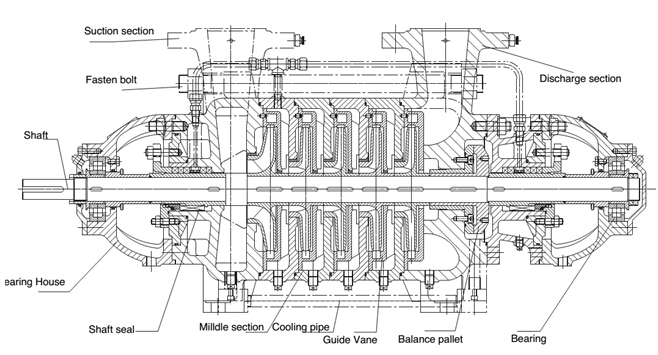

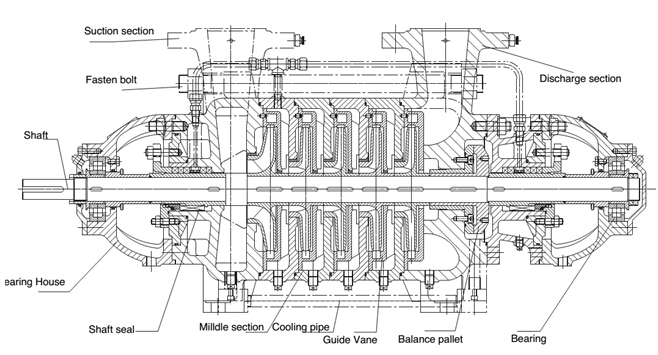

Multistage Pump Structure and Water Usage centrifugal pump  Product Description General Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar to those of pure water. QD model middle and low pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 120℃, and is also applicable for small boiler water supply or transporting medium similar to hotwater. QDG model hypo-high-pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 180℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. Performance range of mode QD (G) series Flow: 3-684m3/h Corollary power: 4-3400kW Head: 15.78-684m Inlet diameter: 25-450mm Pump Structure Structure of QD boiler water feed multistage pump For this series horizontal multistage centrifugal pump, both ends of it are supported, the casing portion is in a sectional form. it is connected to and actuated by a motor via a resilient clutch and the rotating direction of it. viewing from the actuating end. is clockwise. Refer to Fig. I for the structure of it. Stator portion Consists of suck-in section. middle-section, spitting section, guide vane, packing etc., which are linked together with a take-up bolt. with both suck-in and spitting mouths vertically upward. Rotor portion Consists of a shaft, impeller, balancing disk, muff etc. Parts. Bearing portion The whole rotor is supported by the roller bearings or sliding bearings on both ends of the shaft and the bearings are lubricated with grease or 20# engin oil. Cooling and seal of pump The joint-part between suction section, intermediate section and discharge section with be coated with molybdenum disulfide lubricating grease as seal. Rotor and fixed parts will be sealed by seal ring, guide-vane jacket and packing. The packing tensile degree of shaft seal should be proper and seep should be feasible dip by dip Unload run should be forbid. The seal ring and guide vane jacket should be replaced if they are too worn to be used any more and even do harm to pump work. There is spare shaft sleeve near shaft seal to protect shaft of pump.

Product Description General Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar to those of pure water. QD model middle and low pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 120℃, and is also applicable for small boiler water supply or transporting medium similar to hotwater. QDG model hypo-high-pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 180℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. Performance range of mode QD (G) series Flow: 3-684m3/h Corollary power: 4-3400kW Head: 15.78-684m Inlet diameter: 25-450mm Pump Structure Structure of QD boiler water feed multistage pump For this series horizontal multistage centrifugal pump, both ends of it are supported, the casing portion is in a sectional form. it is connected to and actuated by a motor via a resilient clutch and the rotating direction of it. viewing from the actuating end. is clockwise. Refer to Fig. I for the structure of it. Stator portion Consists of suck-in section. middle-section, spitting section, guide vane, packing etc., which are linked together with a take-up bolt. with both suck-in and spitting mouths vertically upward. Rotor portion Consists of a shaft, impeller, balancing disk, muff etc. Parts. Bearing portion The whole rotor is supported by the roller bearings or sliding bearings on both ends of the shaft and the bearings are lubricated with grease or 20# engin oil. Cooling and seal of pump The joint-part between suction section, intermediate section and discharge section with be coated with molybdenum disulfide lubricating grease as seal. Rotor and fixed parts will be sealed by seal ring, guide-vane jacket and packing. The packing tensile degree of shaft seal should be proper and seep should be feasible dip by dip Unload run should be forbid. The seal ring and guide vane jacket should be replaced if they are too worn to be used any more and even do harm to pump work. There is spare shaft sleeve near shaft seal to protect shaft of pump.  Pump Performance Performance data for QD multistage boiler feed water pump

Pump Performance Performance data for QD multistage boiler feed water pump

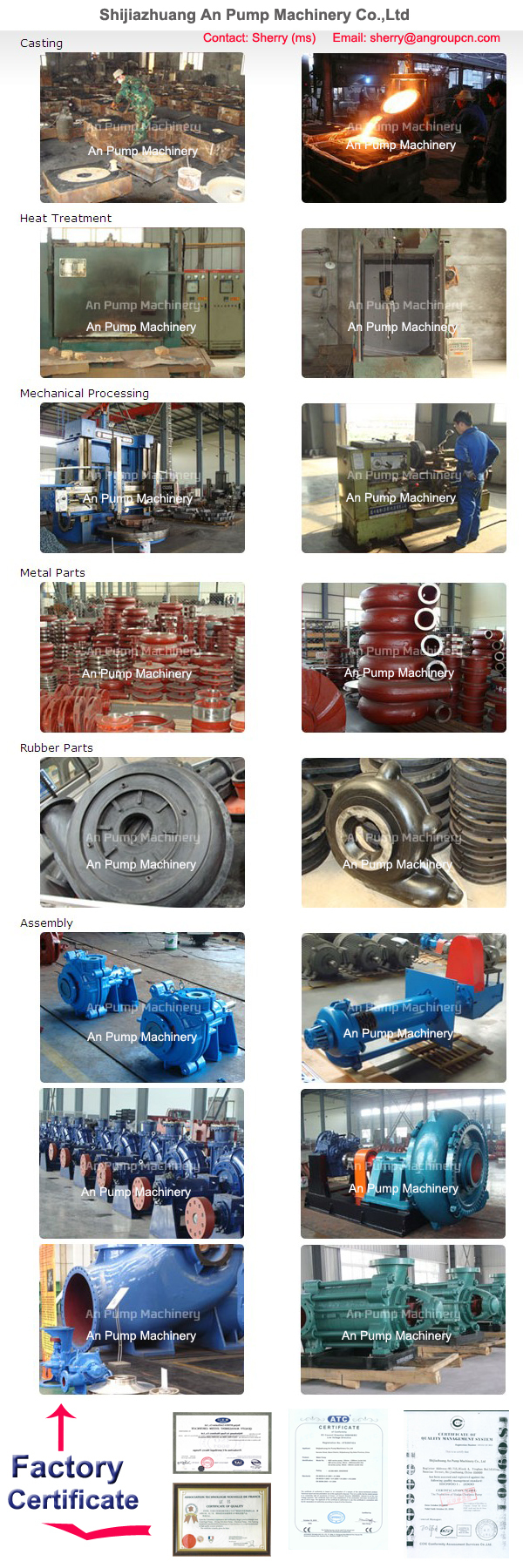

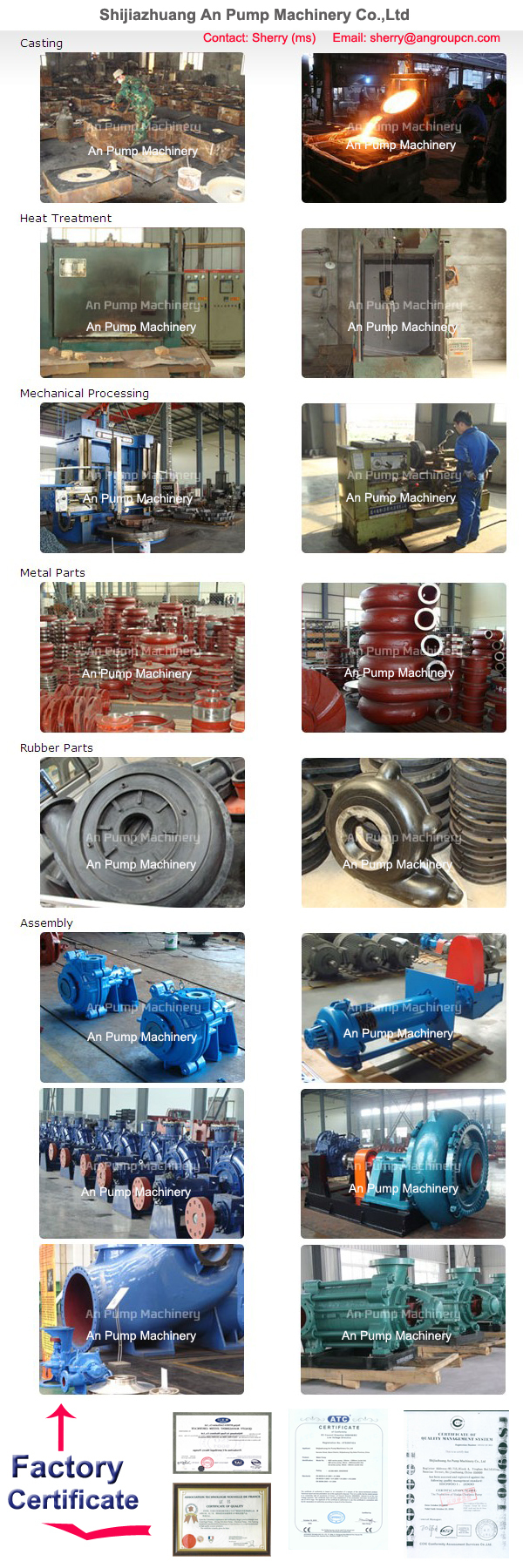

Pump Application Application for QD boiler water feed multistage pump Long distance water transferring Boiling water feeding and transferring Fire fighting Water system boosting Mining industry Power station and water plant Offshore projects All other application for high pressure liquid. Sprinkler irrigation pump  FAQ FAQ 1. Q: Are you a trading company or manufacture? A: An Pump Machinery Co., Ltd is a real large professional manufacturer more than 32 years, in China, produce with our own factory. 2. Q: what's your factory workshops ? A: My factory produce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc. Warmly welcome to visit & test my factory any time. 3. Q: How about your multistage pump price? A: We are sure our price is factory price, and insist hig quality for our long term cooperation.

FAQ FAQ 1. Q: Are you a trading company or manufacture? A: An Pump Machinery Co., Ltd is a real large professional manufacturer more than 32 years, in China, produce with our own factory. 2. Q: what's your factory workshops ? A: My factory produce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc. Warmly welcome to visit & test my factory any time. 3. Q: How about your multistage pump price? A: We are sure our price is factory price, and insist hig quality for our long term cooperation.

4. Q: What is your QD series multistage pump material ?

A: QD series multistage boiler feed water pump, we could produce cast iron, cast steel, stainless steel, bronze etc. Produce as your requirements is ok.

5.Q: What kind of liquid can your QD multistage pump transfer?

A: Liquid range: water, hot water, sewage, chemical liquid, waster water etc. 6. Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~30 QC.

7. Q: Is it easy for customers to change the parts by myselves ?

A: yes, the structure is simple ,customers can change it very easliy. We will also supply you maintenance tools for free.

8. Q: How to do if the pump or parts have operatation problem within your warranty?

A: Tell me details timely, and show me pictures, we will send you solution at once without any hesistation.

9. Q: Can you install the motor or diesel engine driven with the pump for us ?

A: yes, we can, it's no problem, we are experienced in this . 10: Q: .we don't know which pump model we need ,can you help us ?

A: yes, please tell me your detail requirements, include liquid, flow rate, head etc, my engineers team wiil calculate & select most suitable pump model for you, offer pump solution for you.

11. Q:How long can you reply us if we send an inquiry ?

A: Generall within 2 hours, we will send you official quotation sheet, with price, technology data, performance curve, dimension etc. 12. Q: How can i contact you ? A: Contact detail onformation Sherry Lee (Ms) Email: sherry@angroupcn dot com Online Skype ID: pump_sales_sherry Whatsapp No: 008615233116920 Anything thing need help, please call me any time, i will try best to help you. Factory Factory of An Pump Machinery Packaging & Shipping Package for multistage boiler feed water pump

Packaging & Shipping Package for multistage boiler feed water pump  Shipping for multistage pump

Shipping for multistage pump  Company Information Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving products. An Pump Machinery Co., Ltd to our Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock.

Company Information Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving products. An Pump Machinery Co., Ltd to our Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock.

Product Description General Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar to those of pure water. QD model middle and low pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 120℃, and is also applicable for small boiler water supply or transporting medium similar to hotwater. QDG model hypo-high-pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 180℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. Performance range of mode QD (G) series Flow: 3-684m3/h Corollary power: 4-3400kW Head: 15.78-684m Inlet diameter: 25-450mm Pump Structure Structure of QD boiler water feed multistage pump For this series horizontal multistage centrifugal pump, both ends of it are supported, the casing portion is in a sectional form. it is connected to and actuated by a motor via a resilient clutch and the rotating direction of it. viewing from the actuating end. is clockwise. Refer to Fig. I for the structure of it. Stator portion Consists of suck-in section. middle-section, spitting section, guide vane, packing etc., which are linked together with a take-up bolt. with both suck-in and spitting mouths vertically upward. Rotor portion Consists of a shaft, impeller, balancing disk, muff etc. Parts. Bearing portion The whole rotor is supported by the roller bearings or sliding bearings on both ends of the shaft and the bearings are lubricated with grease or 20# engin oil. Cooling and seal of pump The joint-part between suction section, intermediate section and discharge section with be coated with molybdenum disulfide lubricating grease as seal. Rotor and fixed parts will be sealed by seal ring, guide-vane jacket and packing. The packing tensile degree of shaft seal should be proper and seep should be feasible dip by dip Unload run should be forbid. The seal ring and guide vane jacket should be replaced if they are too worn to be used any more and even do harm to pump work. There is spare shaft sleeve near shaft seal to protect shaft of pump.

Product Description General Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar to those of pure water. QD model middle and low pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 120℃, and is also applicable for small boiler water supply or transporting medium similar to hotwater. QDG model hypo-high-pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 180℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. Performance range of mode QD (G) series Flow: 3-684m3/h Corollary power: 4-3400kW Head: 15.78-684m Inlet diameter: 25-450mm Pump Structure Structure of QD boiler water feed multistage pump For this series horizontal multistage centrifugal pump, both ends of it are supported, the casing portion is in a sectional form. it is connected to and actuated by a motor via a resilient clutch and the rotating direction of it. viewing from the actuating end. is clockwise. Refer to Fig. I for the structure of it. Stator portion Consists of suck-in section. middle-section, spitting section, guide vane, packing etc., which are linked together with a take-up bolt. with both suck-in and spitting mouths vertically upward. Rotor portion Consists of a shaft, impeller, balancing disk, muff etc. Parts. Bearing portion The whole rotor is supported by the roller bearings or sliding bearings on both ends of the shaft and the bearings are lubricated with grease or 20# engin oil. Cooling and seal of pump The joint-part between suction section, intermediate section and discharge section with be coated with molybdenum disulfide lubricating grease as seal. Rotor and fixed parts will be sealed by seal ring, guide-vane jacket and packing. The packing tensile degree of shaft seal should be proper and seep should be feasible dip by dip Unload run should be forbid. The seal ring and guide vane jacket should be replaced if they are too worn to be used any more and even do harm to pump work. There is spare shaft sleeve near shaft seal to protect shaft of pump.  Pump Performance Performance data for QD multistage boiler feed water pump

Pump Performance Performance data for QD multistage boiler feed water pump QD(G) Series multistage pump data | |||

Pump Type | Flow | Head | Power |

(m3/h) | (m) | (KW) | |

QM(G) 6-25 | 3-7.5 | 73.5-306 | 4-11 |

QM(G) 12-25 | 7.5-15 | 69-338.4 | 5.5-22 |

QM(G) 12-50 | 7.5-15 | 139.5-648 | 18.5-75 |

QM(G) 25-30 | 15-30 | 82.5-340 | 15-45 |

QM(G) 25-50 | 15-30 | 15.78-618 | 22-110 |

QM(G) 46-30 | 30-55 | 81-340 | 22-75 |

QM(G) 46-50 | 30-55 | 138-666 | 37-132 |

QM(G) 85-45 | 55-100 | 78-459 | 37-160 |

QM(G) 85-67 | 55-100 | 183-666 | 90-250 |

QM(G) 155-67 | 100-185 | 177-684 | 132-400 |

QM(G) 280-43 | 185-335 | 114-423 | 160-450 |

QM(G)280-65 | 185-355 | 372-680 | 500-800 |

QM(G)450-60 | 335-684 | 171-650 | 360-3400 |

FAQ FAQ 1. Q: Are you a trading company or manufacture? A: An Pump Machinery Co., Ltd is a real large professional manufacturer more than 32 years, in China, produce with our own factory. 2. Q: what's your factory workshops ? A: My factory produce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc. Warmly welcome to visit & test my factory any time. 3. Q: How about your multistage pump price? A: We are sure our price is factory price, and insist hig quality for our long term cooperation.

FAQ FAQ 1. Q: Are you a trading company or manufacture? A: An Pump Machinery Co., Ltd is a real large professional manufacturer more than 32 years, in China, produce with our own factory. 2. Q: what's your factory workshops ? A: My factory produce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc. Warmly welcome to visit & test my factory any time. 3. Q: How about your multistage pump price? A: We are sure our price is factory price, and insist hig quality for our long term cooperation. 4. Q: What is your QD series multistage pump material ?

A: QD series multistage boiler feed water pump, we could produce cast iron, cast steel, stainless steel, bronze etc. Produce as your requirements is ok.

5.Q: What kind of liquid can your QD multistage pump transfer?

A: Liquid range: water, hot water, sewage, chemical liquid, waster water etc. 6. Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has 15~30 QC.

7. Q: Is it easy for customers to change the parts by myselves ?

A: yes, the structure is simple ,customers can change it very easliy. We will also supply you maintenance tools for free.

8. Q: How to do if the pump or parts have operatation problem within your warranty?

A: Tell me details timely, and show me pictures, we will send you solution at once without any hesistation.

9. Q: Can you install the motor or diesel engine driven with the pump for us ?

A: yes, we can, it's no problem, we are experienced in this . 10: Q: .we don't know which pump model we need ,can you help us ?

A: yes, please tell me your detail requirements, include liquid, flow rate, head etc, my engineers team wiil calculate & select most suitable pump model for you, offer pump solution for you.

11. Q:How long can you reply us if we send an inquiry ?

A: Generall within 2 hours, we will send you official quotation sheet, with price, technology data, performance curve, dimension etc. 12. Q: How can i contact you ? A: Contact detail onformation Sherry Lee (Ms) Email: sherry@angroupcn dot com Online Skype ID: pump_sales_sherry Whatsapp No: 008615233116920 Anything thing need help, please call me any time, i will try best to help you. Factory Factory of An Pump Machinery

Packaging & Shipping Package for multistage boiler feed water pump

Packaging & Shipping Package for multistage boiler feed water pump  Shipping for multistage pump

Shipping for multistage pump  Company Information Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving products. An Pump Machinery Co., Ltd to our Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock.

Company Information Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving products. An Pump Machinery Co., Ltd to our Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock.