QDG Horizontal Multistage Boiler Feed Water Pump

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Pump Application Diesel engine multistage high pressure high head water pump

Pump Application Diesel engine multistage high pressure high head water pump  1.Irrigation 2.High-rise buildings water supply and drainage, and for fire working

1.Irrigation 2.High-rise buildings water supply and drainage, and for fire working3.Factory and mining for distance water supply and drainage

4.Circulation water supply for production process

5.Cooling systems of air-conditioning in hotels

6.Domestic water supply Pump Performance Diesel engine multistage high pressure high head water pump

QD(G) Series multistage pump data | |||

Pump Type | Flow | Head | Power |

(m3/h) | (m) | (KW) | |

QD(G) 6-25 | 3-7.5 | 73.5-306 | 4-11 |

QD(G) 12-25 | 7.5-15 | 69-338.4 | 5.5-22 |

QD(G) 12-50 | 7.5-15 | 139.5-648 | 18.5-75 |

QD(G) 25-30 | 15-30 | 82.5-340 | 15-45 |

QD(G) 25-50 | 15-30 | 15.78-618 | 22-110 |

QD(G) 46-30 | 30-55 | 81-340 | 22-75 |

QD(G) 46-50 | 30-55 | 138-666 | 37-132 |

QD(G) 85-45 | 55-100 | 78-459 | 37-160 |

QD(G) 85-67 | 55-100 | 183-666 | 90-250 |

QD(G) 155-67 | 100-185 | 177-684 | 132-400 |

QD(G) 280-43 | 185-335 | 114-423 | 160-450 |

QD(G)280-65 | 185-355 | 372-680 | 500-800 |

QD(G)450-60 | 335-684 | 171-650 | 360-3400 |

Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar to those of pure water.

Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar to those of pure water.QD (G) model middle and low pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 120℃, and is also applicable for small boiler water supply or transporting medium similar to hotwater.

QDG model hypo-high-pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 180℃, and is also applicable for small boiler water supply or transporting medium similar to hot water.

Performance range of mode QD (G) series

Flow: 3-684m3/h Corollary power: 4-3400kW

Head: 15.78-684m Inlet diameter: 25-450mm Pump Structure

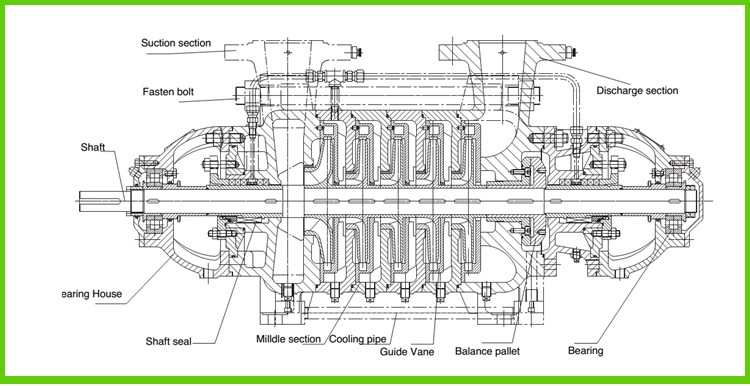

Structure For this series horizontal multistage centrifugal pump, both ends of it are supported, the casing portion is in a sectional form. it is connected to and actuated by a motor via a resilient clutch and the rotating direction of it. viewing from the actuating end. is clockwise. Refer to Fig. I for the structure of it. Stator portion

Structure For this series horizontal multistage centrifugal pump, both ends of it are supported, the casing portion is in a sectional form. it is connected to and actuated by a motor via a resilient clutch and the rotating direction of it. viewing from the actuating end. is clockwise. Refer to Fig. I for the structure of it. Stator portionConsists of suck-in section. middle-section, spitting section, guide vane, packing etc., which are linked together with a take-up bolt. with both suck-in and spitting mouths vertically upward. Rotor portion

Consists of a shaft, impeller, balancing disk, muff etc. Parts. Bearing portion

The whole rotor is supported by the roller bearings or

sliding bearings on both ends of the shaft and the bearings are lubricated with grease or 20# engin oil. Cooling and seal of pump

The joint-part between suction section, intermediate section and discharge section with be coated with molybdenum disulfide lubricating grease as seal. Rotor and fixed parts will be sealed by seal ring, guide-vane jacket and packing. The packing tensile degree of shaft seal should be proper and seep should be feasible dip by dip Unload run should be forbid. The seal ring and guide vane jacket should be replaced if they are too worn to be used any more and even do harm to pump work. There is spare shaft sleeve near shaft seal to protect shaft of pump. Our Team

Client Visit

Client Visit

Contact Us

Contact Us

Related Keywords

Related Keywords