Multistage boiler feed water pump for industrial

- Delivery Time:

- 10 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Multistage boiler feed water pump for industrial  Product Description Multistage boiler feed water pump for industrial details Specifications Centrifugal Multistage Boiler Water Feed Pump 1. Dischage:1''-18''

Product Description Multistage boiler feed water pump for industrial details Specifications Centrifugal Multistage Boiler Water Feed Pump 1. Dischage:1''-18''

2. Head: 2500 M

3.Capacity: 11000m3/h

4.Up to 12 stage 5.Low NPSH Multistage boiler feed water pump for industrial introduction This serial pump is multi-stage section centrifugal pump, the excellent hydraulic models are high-efficiency, energy-saving, and have wide performance range, operating safety & steady, low noise, long life and installing & repairing is very convenient etc. It can deliver heat water, oil, corrosive or wearalbe medium by changing the material, seal or adding cooling system.

1. The multi stage pump can deliver the neuter mineral water which solid particles percent≤ 1.5%(solid Dia, < 0.5mm) and other similar sewage, 2. Temperature of the liquid is ≤ 80° C. It is suitable for steel works, mines, cities projects etc.

This kind pump can deliver the corrosive liquid without solid particle, which temperature is from -20° C-150° C

The multi stage pump deliver oil or oil products without solid grain, viscosity ≤ 120ct, range of temperature is from -20 ° C to 150 ° C Multistage boiler feed water pump for industrial specification

Multistage boiler feed water pump for industrial technical data ♦ D multi impeller and centrifugal multistage pump ♦ Working Principle: Centrifugal ♦ Main applications: Water ♦ Driver: Electric Motor or Diesel Engine ♦ Max Liquid Temperature: 150°C ♦ Type of connection: Flange ♦ Casing Material: cast steel, stainless steel ♦ Impeller Material: cast steel, stainless steel ♦ Seal: mechanical seal/packing seal ♦ Flow Range: 120~1100m3/h ♦ Head: 967~2500m Multistage boiler feed water pump for industrial structure

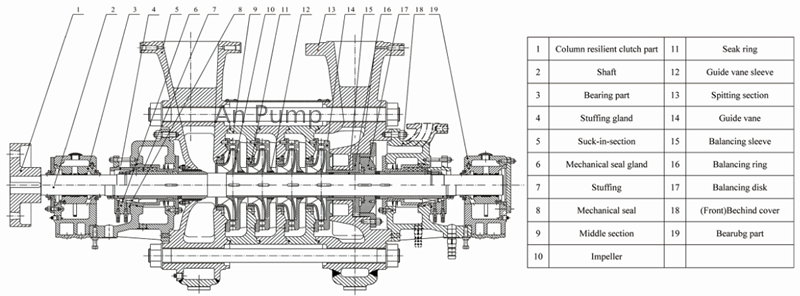

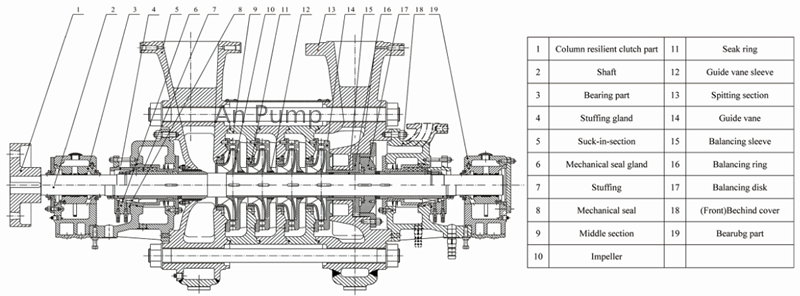

The multi stage pump is consist of stator, rotator, bearing, shaft seal:

1. Stator: The main parts are suction casing, stage casing, discharge casing and diffuser. They are screw up by poles, to become a working house. It is horizontal, the discharge direction is upward; The discharge and suction direction of them are both upwards, and the suction direction is horizontal usually, also they can be made upward according to user's requirement.

2. Rotor: It is consist of shaft, impellers, balance dic and shaft sleeve etc. Shaft supplied power to impellers; The axial force is balanced by balance disc; The sleeve mounted on shaft to protect shaft.

3. Bearing parts: It is consist of bearing body, bearing and bearing cover etc. The bearing of type 85-67, 155-67, 600-60 pump is sliding bearing, lubricated by diluted oil, the other pump bearing is rolling bearing, lubricated by grease.

4. Shaft seal: It is usually adopted soft packing seal, consist of sealing house on suction casing, packing, blocking water ring, the sealing hose have some pressure water, to cool, lubricate and seal pump. The pumps usually adopt mechanical seal.

5. Drive: The pump is driven directly by motor through elastic coumpling, the rotation of pump is clockwise looking from motor to pump.

Our company also can design according to your requirement Product Show

Product Show  Packaging & Shipping Multistage boiler feed water pump for industrial packing and shipping

Packaging & Shipping Multistage boiler feed water pump for industrial packing and shipping

Our Services Our Services 1. Offer Large capacity pump solutions

Our Services Our Services 1. Offer Large capacity pump solutions

2. Selection

3. OEM available

4. ODM available

5. Design

6. Installation

7. Maintenance Company Information

Company Information  Our Main Products

Our Main Products  Some clients visit our factory

Some clients visit our factory  Contact Us

Contact Us  Learn more , please contact us directly.

Learn more , please contact us directly.

Product Description Multistage boiler feed water pump for industrial details Specifications Centrifugal Multistage Boiler Water Feed Pump 1. Dischage:1''-18''

Product Description Multistage boiler feed water pump for industrial details Specifications Centrifugal Multistage Boiler Water Feed Pump 1. Dischage:1''-18'' 2. Head: 2500 M

3.Capacity: 11000m3/h

4.Up to 12 stage 5.Low NPSH Multistage boiler feed water pump for industrial introduction This serial pump is multi-stage section centrifugal pump, the excellent hydraulic models are high-efficiency, energy-saving, and have wide performance range, operating safety & steady, low noise, long life and installing & repairing is very convenient etc. It can deliver heat water, oil, corrosive or wearalbe medium by changing the material, seal or adding cooling system.

1. The multi stage pump can deliver the neuter mineral water which solid particles percent≤ 1.5%(solid Dia, < 0.5mm) and other similar sewage, 2. Temperature of the liquid is ≤ 80° C. It is suitable for steel works, mines, cities projects etc.

This kind pump can deliver the corrosive liquid without solid particle, which temperature is from -20° C-150° C

The multi stage pump deliver oil or oil products without solid grain, viscosity ≤ 120ct, range of temperature is from -20 ° C to 150 ° C Multistage boiler feed water pump for industrial specification

Type | QD(G) |

Capacity (m3/h) | 120-11000 |

Head (m) | 967-2500 |

Speed (r/min) | 2980-5410 |

Eff.(%) | 86-96 |

NPSHr (m) | 4.5-23.5 |

Power (kw) | 710-8000 |

The multi stage pump is consist of stator, rotator, bearing, shaft seal:

1. Stator: The main parts are suction casing, stage casing, discharge casing and diffuser. They are screw up by poles, to become a working house. It is horizontal, the discharge direction is upward; The discharge and suction direction of them are both upwards, and the suction direction is horizontal usually, also they can be made upward according to user's requirement.

2. Rotor: It is consist of shaft, impellers, balance dic and shaft sleeve etc. Shaft supplied power to impellers; The axial force is balanced by balance disc; The sleeve mounted on shaft to protect shaft.

3. Bearing parts: It is consist of bearing body, bearing and bearing cover etc. The bearing of type 85-67, 155-67, 600-60 pump is sliding bearing, lubricated by diluted oil, the other pump bearing is rolling bearing, lubricated by grease.

4. Shaft seal: It is usually adopted soft packing seal, consist of sealing house on suction casing, packing, blocking water ring, the sealing hose have some pressure water, to cool, lubricate and seal pump. The pumps usually adopt mechanical seal.

5. Drive: The pump is driven directly by motor through elastic coumpling, the rotation of pump is clockwise looking from motor to pump.

Our company also can design according to your requirement

Product Show

Product Show  Packaging & Shipping Multistage boiler feed water pump for industrial packing and shipping

Packaging & Shipping Multistage boiler feed water pump for industrial packing and shipping

Our Services Our Services 1. Offer Large capacity pump solutions

Our Services Our Services 1. Offer Large capacity pump solutions2. Selection

3. OEM available

4. ODM available

5. Design

6. Installation

7. Maintenance

Company Information

Company Information  Our Main Products

Our Main Products  Some clients visit our factory

Some clients visit our factory  Contact Us

Contact Us  Learn more , please contact us directly.

Learn more , please contact us directly. Related Keywords

Related Keywords