High pressure horizontal multistage centrifugal pump for boiler water feeding

- Delivery Time:

- 9 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

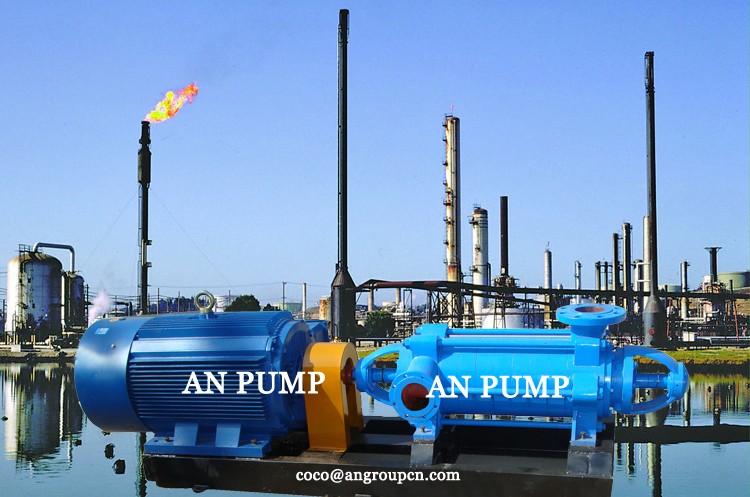

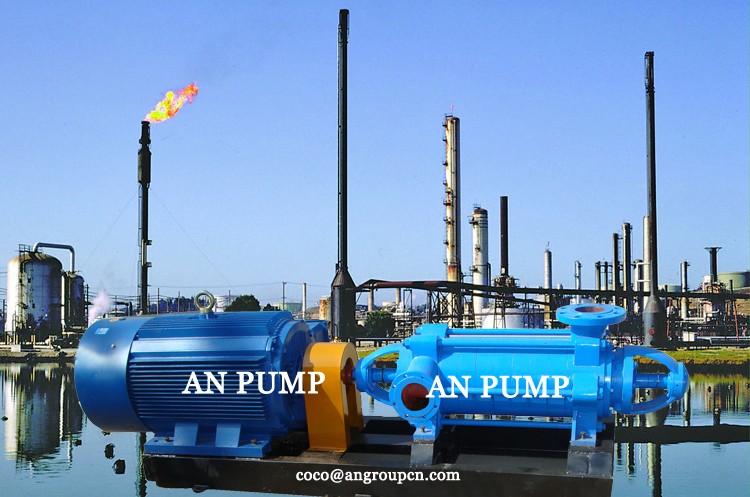

High pressure horizontal multistage centrifugal pump for boiler water feeding  Product Description General of High pressure horizontal multistage centrifugal pump for boiler water feeding Model QD multi stages is a horizontal multistage centrifugal water feed boiler pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar with those of pure water. QD model middle and low pressure boiler water supply multistage pump is applicable to transport medium with temperature of not higher than 105℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. QDG model is used to transport medium with temperature of not higher than 160℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. Specification Size: 25 - 450 mm

Product Description General of High pressure horizontal multistage centrifugal pump for boiler water feeding Model QD multi stages is a horizontal multistage centrifugal water feed boiler pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar with those of pure water. QD model middle and low pressure boiler water supply multistage pump is applicable to transport medium with temperature of not higher than 105℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. QDG model is used to transport medium with temperature of not higher than 160℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. Specification Size: 25 - 450 mm

Flow: 3 - 684 m3/hr

Head: 15 - 680 m

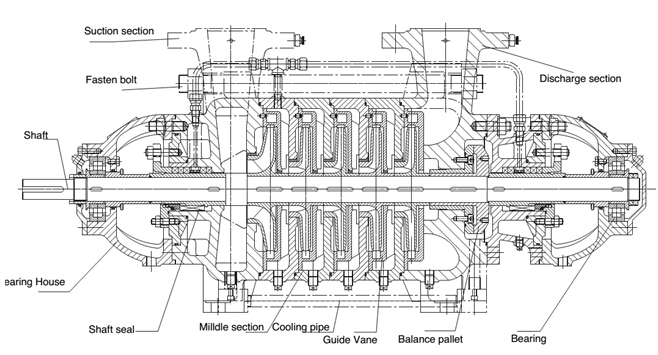

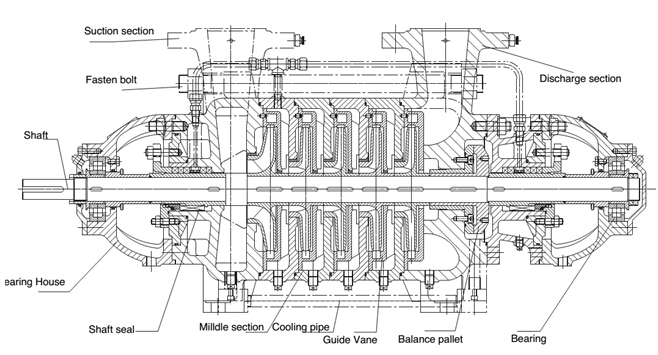

Speed: 1450 - 2900 rpm structure of High pressure horizontal multistage centrifugal pump for boiler water feeding

1. The QD series multi stages pump are sectional casing,multistage centrifugal pumps. The suction casing, stage casing and discharge casings are rigidly held together by tie bolts. The joints between these casings are primarily sealed by means of metal-metal contact. Simultaneously,O-rings are used as auxiliary seals. 2. The shafts of these pumps are sealed by soft-packing and cooling water. Mechanical seal can be used according to the client's requirement. 3. The rotating assembly is supported by sliding bearings on both ends of the pump shaft. Bearings of pump are forced-lubricated. The oil system is equipped for type QD(G) pump The axial thrust of rotor is balanced by balance disc. And the thrust bearing is also provided which is sed to bear residual axial force caused by the change of working conditions. The assembly quality of the boiler pump will result in a notable affection to the performance and the running stability of it and can not be guaranteed unless the technical requirements in the drawings are strictly followed in the assembly, such as on the alignment between the centers of the impeller’s outlet and the guide vane's inlet. the uniform values of the sealing intervals of both rotor and stator portions etc. Covering angle and central line posit ion adjustment. check the equipments at least in the fol lowing three periods and take adjustment: The first time, both the multi stages pump and foundation are secured while the motor is not. The second time, both pump and motor are secured while the bolts on the suck-in and spitting pipeline flanges are not. The third time is in 24 hours after the pump starts running,then secure both pump and motor Pump Application: High pressure horizontal multistage centrifugal pump for boiler water feeding application Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar

Pump Application: High pressure horizontal multistage centrifugal pump for boiler water feeding application Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar

those of pure water.

QD (G) model middle and low pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 105℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. Packaging & Shipping Standard wooden cases package, if special requirements, should be inform in advance

Packaging & Shipping Standard wooden cases package, if special requirements, should be inform in advance

Shipping by sea, by air, by train and truck all available

Delivery date: vary from 5-30days according to different model and quantity. Our Services 1 year guarantee of whole machine set, except the flow parts 24hours *7 days service is available Calling or door to door service User manual and maintenance instruction is available Company Information

Our Services 1 year guarantee of whole machine set, except the flow parts 24hours *7 days service is available Calling or door to door service User manual and maintenance instruction is available Company Information  Our Main Products

Our Main Products  Some clients visit our factory

Some clients visit our factory  Contact Us

Contact Us  Learn more , please contact us directly. Mandy Wang

Learn more , please contact us directly. Mandy Wang

International Dept. Shijiazhuang An pump Machinery Co.,Ltd Web:www.angroupcn.com Email:coco(@)angroupcn.com Tel:86-311-89940549 Fax:86-311-86271170 International calls:86 15032857866 WhatsApp:008613731071183 Skype:mandy.anpump

Product Description General of High pressure horizontal multistage centrifugal pump for boiler water feeding Model QD multi stages is a horizontal multistage centrifugal water feed boiler pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar with those of pure water. QD model middle and low pressure boiler water supply multistage pump is applicable to transport medium with temperature of not higher than 105℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. QDG model is used to transport medium with temperature of not higher than 160℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. Specification Size: 25 - 450 mm

Product Description General of High pressure horizontal multistage centrifugal pump for boiler water feeding Model QD multi stages is a horizontal multistage centrifugal water feed boiler pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar with those of pure water. QD model middle and low pressure boiler water supply multistage pump is applicable to transport medium with temperature of not higher than 105℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. QDG model is used to transport medium with temperature of not higher than 160℃, and is also applicable for small boiler water supply or transporting medium similar to hot water. Specification Size: 25 - 450 mmFlow: 3 - 684 m3/hr

Head: 15 - 680 m

Speed: 1450 - 2900 rpm structure of High pressure horizontal multistage centrifugal pump for boiler water feeding

1. The QD series multi stages pump are sectional casing,multistage centrifugal pumps. The suction casing, stage casing and discharge casings are rigidly held together by tie bolts. The joints between these casings are primarily sealed by means of metal-metal contact. Simultaneously,O-rings are used as auxiliary seals. 2. The shafts of these pumps are sealed by soft-packing and cooling water. Mechanical seal can be used according to the client's requirement. 3. The rotating assembly is supported by sliding bearings on both ends of the pump shaft. Bearings of pump are forced-lubricated. The oil system is equipped for type QD(G) pump The axial thrust of rotor is balanced by balance disc. And the thrust bearing is also provided which is sed to bear residual axial force caused by the change of working conditions. The assembly quality of the boiler pump will result in a notable affection to the performance and the running stability of it and can not be guaranteed unless the technical requirements in the drawings are strictly followed in the assembly, such as on the alignment between the centers of the impeller’s outlet and the guide vane's inlet. the uniform values of the sealing intervals of both rotor and stator portions etc. Covering angle and central line posit ion adjustment. check the equipments at least in the fol lowing three periods and take adjustment: The first time, both the multi stages pump and foundation are secured while the motor is not. The second time, both pump and motor are secured while the bolts on the suck-in and spitting pipeline flanges are not. The third time is in 24 hours after the pump starts running,then secure both pump and motor

Pump Application: High pressure horizontal multistage centrifugal pump for boiler water feeding application Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar

Pump Application: High pressure horizontal multistage centrifugal pump for boiler water feeding application Model QD (G) pump is a horizontal multi-stage centrifugal pump and suitable for transporting pure water (with the contained foreign matters' content less than l % and graininess less than 0. 1mm) and other liquids of both physical and chemical natures similar those of pure water.

QD (G) model middle and low pressure boiler water supply pump is applicable to transport medium with temperature of not higher than 105℃, and is also applicable for small boiler water supply or transporting medium similar to hot water.

Packaging & Shipping Standard wooden cases package, if special requirements, should be inform in advance

Packaging & Shipping Standard wooden cases package, if special requirements, should be inform in advanceShipping by sea, by air, by train and truck all available

Delivery date: vary from 5-30days according to different model and quantity.

Our Services 1 year guarantee of whole machine set, except the flow parts 24hours *7 days service is available Calling or door to door service User manual and maintenance instruction is available Company Information

Our Services 1 year guarantee of whole machine set, except the flow parts 24hours *7 days service is available Calling or door to door service User manual and maintenance instruction is available Company Information  Our Main Products

Our Main Products  Some clients visit our factory

Some clients visit our factory  Contact Us

Contact Us  Learn more , please contact us directly. Mandy Wang

Learn more , please contact us directly. Mandy WangInternational Dept. Shijiazhuang An pump Machinery Co.,Ltd Web:www.angroupcn.com Email:coco(@)angroupcn.com Tel:86-311-89940549 Fax:86-311-86271170 International calls:86 15032857866 WhatsApp:008613731071183 Skype:mandy.anpump

Related Keywords

Related Keywords