Vertical submersible sludge pump/sewage effluent pump

- Delivery Time:

- 10 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Vertical submersible sewage pump sludge pump effluent pump  Product Description

Product Description  1.Introduction of submersible sewage pump sludge pump effluent pump ASW non-clog stainless steel submersible sewage pump is one of our main product of An Pump. It is not only popular with customers at home, but also in abroad. The full moulds of this pump is opened by ourselves. This product is casted by the stainless steel material integrally and the pump shell and impeller are precision casted by stainless steel material as well. The enough thicknessensure the pump has an excellent effect on corrosion resistance, acids and alkali resistance. So ASW stainless steel stainless steel centrifugal pump meet the occasion of corrosive medium like transporting the medium in the chemical plants, sewage treatment plants, factories sewage discharges and so on.

1.Introduction of submersible sewage pump sludge pump effluent pump ASW non-clog stainless steel submersible sewage pump is one of our main product of An Pump. It is not only popular with customers at home, but also in abroad. The full moulds of this pump is opened by ourselves. This product is casted by the stainless steel material integrally and the pump shell and impeller are precision casted by stainless steel material as well. The enough thicknessensure the pump has an excellent effect on corrosion resistance, acids and alkali resistance. So ASW stainless steel stainless steel centrifugal pump meet the occasion of corrosive medium like transporting the medium in the chemical plants, sewage treatment plants, factories sewage discharges and so on.

Stainless steel submersible sewage pump is really a high-performance and high quality type due to its attractive appearance, compact structure and superior performance. 2.Parameter of submersible sewage pump sludge pump effluent pump

3.Structure of submersible sewage pump sludge pump effluent pump

Bearing:

Imported SKF of NTN bearing, which, with a reasonable configuration, can oxtend the duration of the pump.

Cooling:

The buit-in cooling system can have the pump normally work whether the motor is on or under the liquid surface. A part of the liquid is extracted to bring out the beat produced by the motor from the pump circulation to the cooling barrel and to the pump casing and, when external cooling is required, the cooling sleeve may be separated from the pump casing and individually connected to the cooling system.

Motor:

Of F class insulation, max. working temperatures 155 C, and of a protective grade IPX8 with the effective seal.

Mechanical seal:

Use high quality mechanic seal , two ways of the seal are in series with each other and individually work to separate the motor from the pump seal to provide the motor with a dual protection.

Oil chamber:

Oil can lubricate and cool the mechanical seal and realize the attached function of safety by preventing liquid from penetrating into the motor.

Impeller:

With the optimized design, the impeller wil not be blocked up when to transport liquid with its optimum flow and rate and the maximum efficiency. There are suitable impellers at choice for every point of working condition.

Pump casing:

Use the know-how of CAD/CAM to make it of max. efficiency and min wearability

Shaft:

The pump is coaxial with the motor and the sealing device on the end of the shaft preven ts against contacting with the medium to protect is from corrosion. Pump Application: 4. Application of submersible sewage pump sludge pump effluent pump

4. Application of submersible sewage pump sludge pump effluent pump

1.vertical submersible sewage pump for waste water

2.ASW series pump is a kind of submersible sewage motor pump,and the pump and the motor are coaxial.

3.ASW series submersible sewage motor pump mainly used in municipal engineering, industry, hospital,hotel,etc.

4. It is used for pumping sludge , sewage and city life sewage with solids and long fiber (including erosive matters )

5.Our submersible sewage motor pumps have following advantages: hi-efficiency, circumvolution proof,non-block,auto-coupling, hi-reliability and auto-control,etc.

6.The unique cable airproof is adopted, avoiding leakage of cable.

7.Rated Voltage: 380V(660V), Frequency: 50Hz, 3-phase AC. Temperature of medium under 40°C. PH of medium: 4~10. Volume ratio of solid in medium below 2%. .Density of medium should be lower than 1.2*10³kg/m³.

8..Heat protector in stator assures operating life of the motor.

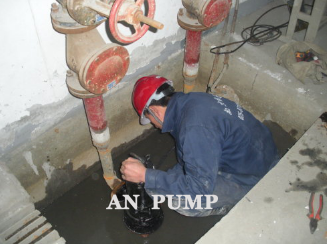

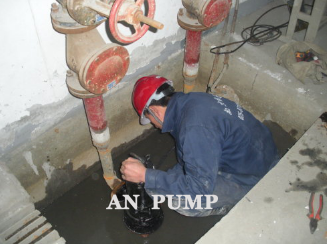

9.Adopt perfect mechanical seal and the sealing material adopt tungsten carbide, silicon carbide and hard metal alloy, so it can prevent the water from entering in the motor, and keep the operating reliable and safety. 1)Building discharge sewage water 2)River or sea used large flow submersible sewage pump

2)River or sea used large flow submersible sewage pump  3)Water-collecting wells used submersible sewage pump

3)Water-collecting wells used submersible sewage pump  Packaging & Shipping

Packaging & Shipping  5. Packing and shipping of submersible sewage pump sludge pump effluent pump

5. Packing and shipping of submersible sewage pump sludge pump effluent pump

Our Services Our Services 1. Offer Large capacity pump solutions

Our Services Our Services 1. Offer Large capacity pump solutions

2. Selection

3. OEM available

4. ODM available

5. Design

6. Installation

7. Maintenance Company Information

Company Information

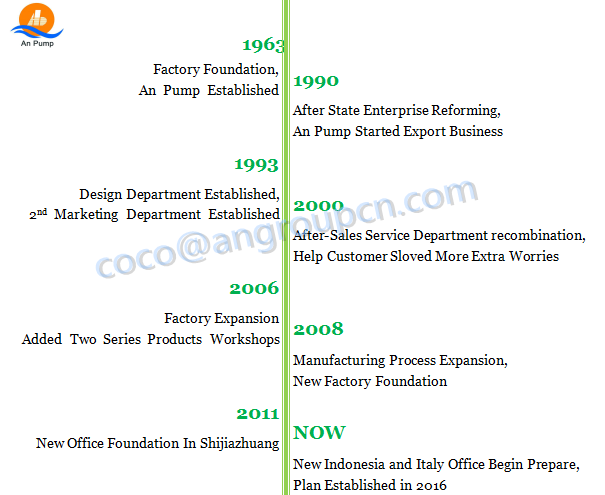

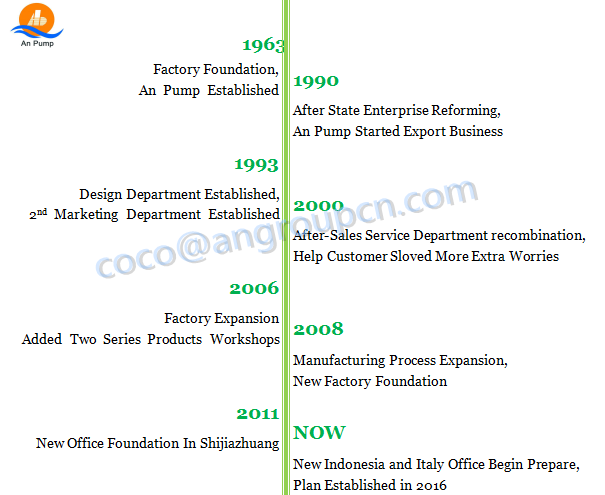

Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps type design, use and maintenance program.

Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps type design, use and maintenance program.  Contact Us

Contact Us  Learn more , please contact us directly. Mandy Wang

Learn more , please contact us directly. Mandy Wang

International Dept. Shijiazhuang An pump Machinery Co.,Ltd Web:www.angroupcn.com Email:coco(@)angroupcn.com Tel:86-311-89940549 Fax:86-311-86271170 WhatsApp:0086-137-3107-1183 Skype:mandy.anpump

Product Description

Product Description  1.Introduction of submersible sewage pump sludge pump effluent pump ASW non-clog stainless steel submersible sewage pump is one of our main product of An Pump. It is not only popular with customers at home, but also in abroad. The full moulds of this pump is opened by ourselves. This product is casted by the stainless steel material integrally and the pump shell and impeller are precision casted by stainless steel material as well. The enough thicknessensure the pump has an excellent effect on corrosion resistance, acids and alkali resistance. So ASW stainless steel stainless steel centrifugal pump meet the occasion of corrosive medium like transporting the medium in the chemical plants, sewage treatment plants, factories sewage discharges and so on.

1.Introduction of submersible sewage pump sludge pump effluent pump ASW non-clog stainless steel submersible sewage pump is one of our main product of An Pump. It is not only popular with customers at home, but also in abroad. The full moulds of this pump is opened by ourselves. This product is casted by the stainless steel material integrally and the pump shell and impeller are precision casted by stainless steel material as well. The enough thicknessensure the pump has an excellent effect on corrosion resistance, acids and alkali resistance. So ASW stainless steel stainless steel centrifugal pump meet the occasion of corrosive medium like transporting the medium in the chemical plants, sewage treatment plants, factories sewage discharges and so on. Stainless steel submersible sewage pump is really a high-performance and high quality type due to its attractive appearance, compact structure and superior performance. 2.Parameter of submersible sewage pump sludge pump effluent pump

Stainless Steel Submersible Sewage Pump Performance | |||||

Type | Flow (m3/h) | Head (m) | Speed (r/min) | Motor Power (KW) | Efficiency (%) |

40ASW | 8.4-14.4 | 14-16 | 2900 | 1.5 | 42-70 |

50ASW | 7-50.4 | 8-36 | 1450-2900 | 0.75-7.5 | 46-62 |

65ASW | 17.5-44.4 | 11-30.2 | 2900 | 2.2-4 | 39-72 |

80ASW | 20.3-72 | 5.7-27.5 | 2900 | 2.2-7.5 | 51-75 |

100ASW | 35-120 | 5.6-38.5 | 1450 | 4-15 | 46-80 |

150ASW | 49-300 | 5.5-44.5 | 1450 | 5.5-37 | 58-82 |

200ASW | 110-480 | 5.7-44.5 | 1450 | 11-75 | 63-83 |

250ASW | 420-840 | 7-35 | 980-1450 | 30-90 | 63-84.5 |

300ASW | 280-1140 | 6.7-27 | 980-1450 | 45-110 | 68-84.5 |

350ASW | 700-1800 | 8-40 | 980 | 45-160 | 68-85 |

400ASW | 1050-2640 | 12-33 | 980 | 132-160 | 71-85 |

500ASW | 1400-3600 | 9-22.5 | 980 | 110-200 | 72-85 |

Bearing:

Imported SKF of NTN bearing, which, with a reasonable configuration, can oxtend the duration of the pump.

Cooling:

The buit-in cooling system can have the pump normally work whether the motor is on or under the liquid surface. A part of the liquid is extracted to bring out the beat produced by the motor from the pump circulation to the cooling barrel and to the pump casing and, when external cooling is required, the cooling sleeve may be separated from the pump casing and individually connected to the cooling system.

Motor:

Of F class insulation, max. working temperatures 155 C, and of a protective grade IPX8 with the effective seal.

Mechanical seal:

Use high quality mechanic seal , two ways of the seal are in series with each other and individually work to separate the motor from the pump seal to provide the motor with a dual protection.

Oil chamber:

Oil can lubricate and cool the mechanical seal and realize the attached function of safety by preventing liquid from penetrating into the motor.

Impeller:

With the optimized design, the impeller wil not be blocked up when to transport liquid with its optimum flow and rate and the maximum efficiency. There are suitable impellers at choice for every point of working condition.

Pump casing:

Use the know-how of CAD/CAM to make it of max. efficiency and min wearability

Shaft:

The pump is coaxial with the motor and the sealing device on the end of the shaft preven ts against contacting with the medium to protect is from corrosion. Pump Application:

4. Application of submersible sewage pump sludge pump effluent pump

4. Application of submersible sewage pump sludge pump effluent pump 1.vertical submersible sewage pump for waste water

2.ASW series pump is a kind of submersible sewage motor pump,and the pump and the motor are coaxial.

3.ASW series submersible sewage motor pump mainly used in municipal engineering, industry, hospital,hotel,etc.

4. It is used for pumping sludge , sewage and city life sewage with solids and long fiber (including erosive matters )

5.Our submersible sewage motor pumps have following advantages: hi-efficiency, circumvolution proof,non-block,auto-coupling, hi-reliability and auto-control,etc.

6.The unique cable airproof is adopted, avoiding leakage of cable.

7.Rated Voltage: 380V(660V), Frequency: 50Hz, 3-phase AC. Temperature of medium under 40°C. PH of medium: 4~10. Volume ratio of solid in medium below 2%. .Density of medium should be lower than 1.2*10³kg/m³.

8..Heat protector in stator assures operating life of the motor.

9.Adopt perfect mechanical seal and the sealing material adopt tungsten carbide, silicon carbide and hard metal alloy, so it can prevent the water from entering in the motor, and keep the operating reliable and safety. 1)Building discharge sewage water

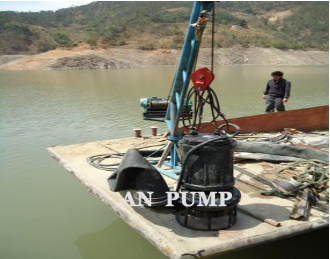

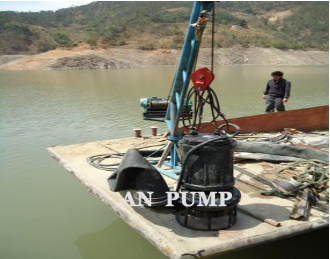

2)River or sea used large flow submersible sewage pump

2)River or sea used large flow submersible sewage pump  3)Water-collecting wells used submersible sewage pump

3)Water-collecting wells used submersible sewage pump  Packaging & Shipping

Packaging & Shipping  5. Packing and shipping of submersible sewage pump sludge pump effluent pump

5. Packing and shipping of submersible sewage pump sludge pump effluent pump

Our Services Our Services 1. Offer Large capacity pump solutions

Our Services Our Services 1. Offer Large capacity pump solutions2. Selection

3. OEM available

4. ODM available

5. Design

6. Installation

7. Maintenance

Company Information

Company Information

Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps type design, use and maintenance program.

Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps type design, use and maintenance program.  Contact Us

Contact Us  Learn more , please contact us directly. Mandy Wang

Learn more , please contact us directly. Mandy WangInternational Dept. Shijiazhuang An pump Machinery Co.,Ltd Web:www.angroupcn.com Email:coco(@)angroupcn.com Tel:86-311-89940549 Fax:86-311-86271170 WhatsApp:0086-137-3107-1183 Skype:mandy.anpump

Related Keywords

Related Keywords