Syrup dispenser pump

- Delivery Time:

- 8 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Syrup dispenser pump

Product Description Syrup dispenser pump advantages 1. High efficiency, Energy saving: operation efficiency is 3-10% higher than ordinary pulp pump, energy saving to 15-30%

Product Description Syrup dispenser pump advantages 1. High efficiency, Energy saving: operation efficiency is 3-10% higher than ordinary pulp pump, energy saving to 15-30%

2. Good NPSH, Long service: actual using life is twice-third time than ordinary pulp pump.

3. High concentrations, Non-clogging: transfer pulp concentration max to 6%.

4. Reasonable structure, Easy maintenance: Pump head is front, rear casing structure, when maintenance there is no need to remove pipe line, only remove the electric motor backwards, then could disassemble and repair the pump. Syrup dispenser pump introduction AJY high efficient energy saving pulp pump, with advantage from broad and domestic, we take advanced design theory to develop new type pump, hydraulic design with theory “relative suction, relative obstruction”. The pump wet parts hydraulic performance is compliance with pump flow law, then reduce the erosion and wear of wet parts by liquid. Greatly improve the pump efficiency and service life. Syrup dispenser pump Model Meaning AJY50-6FY

AJY: Pulp pump

50: Flow rate(capacity) m3/hr

6: Head(pressure) m

F: Material: stainless steel

Y: Shaft seal type: expeller dynamic seal

Pump Material: Ductile Iron(Q), Cast Steel(G), Resistant steel(N), Stainless Steel(F), Duplex Stainless Steel 316(X)

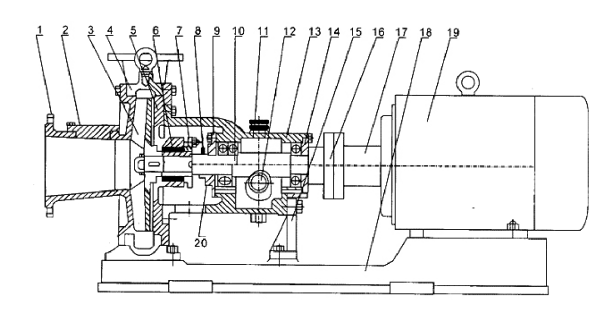

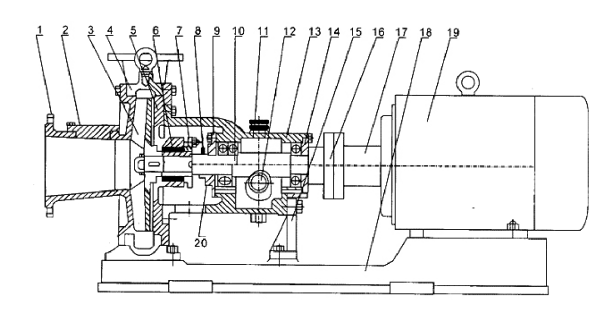

Pump Seal Type: expeller dynamic seal(Y), Single Mechanical Seal(S), Double Mechanical Seal(D) Stainless steel paper pulp pump structure A.B.C.D.E.F.G.H.M.K.N.P.R.Q.S.T.U.V.W category pulp pump main structure Grease, oil lubrication structural parts 1.Front pump cover 3.Impeller 4. Pump casing 5. Pump cover 6. Shaft cover 7. Packing gland 8. Slinger ring 9. Front bearing cover 10. Shaft 11. Breathable cover 12. Oil flag 13. Bearing frame 14. Back bearing cover 15. Support base 16. Coupling on pump end 17. Coupling for motor end 18.Base plate 19. Electric motor 20. Couplingguard Pump Application: Syrup dispenser pump particularly applicable industry

Grease, oil lubrication structural parts 1.Front pump cover 3.Impeller 4. Pump casing 5. Pump cover 6. Shaft cover 7. Packing gland 8. Slinger ring 9. Front bearing cover 10. Shaft 11. Breathable cover 12. Oil flag 13. Bearing frame 14. Back bearing cover 15. Support base 16. Coupling on pump end 17. Coupling for motor end 18.Base plate 19. Electric motor 20. Couplingguard Pump Application: Syrup dispenser pump particularly applicable industry

1. Paper Industry: Suitable for transfer paper pulp concentration max to 6%, and liquid cycle transmission during base recovery processing, for lifting and pressing.

2. Sugar Industry: Suitable for transfer syrup max to 4%, and viscosity max 150 mm2/S.

3. Urban Sewage Treatment, Suitable for transfer sewage, waste water, for lifting and pressing Pump pictures Syrup dispenser pump pictures Our Services Our Services 1. Offer Large capacity pump solutions

Our Services Our Services 1. Offer Large capacity pump solutions

2. Selection

3. OEM available

4. ODM available

5. Design

6. Installation

7. Maintenance Company Information Shijiazhuang An Pump Machinery Co.,Ltd is a manufacturer and trading enterprise, which is mainly engaged in pump designing, manufacturing, selling and service. We develop the international trading business of mining equipment, slurry pumps, and water pumps according the wide customer resource, comprehensive technology and reasonable staffing.

Company Information Shijiazhuang An Pump Machinery Co.,Ltd is a manufacturer and trading enterprise, which is mainly engaged in pump designing, manufacturing, selling and service. We develop the international trading business of mining equipment, slurry pumps, and water pumps according the wide customer resource, comprehensive technology and reasonable staffing.  An pump machinery’s main products includes: slurry pump, desulfurization pump, gravel pump, mud pump, sewage pump, submersible pump, submersible sewage pump, impurity pump, large capacity split casing pump, high head multistage water pump,end suction pump, self priming pump, pump parts and ancillary equipment. which can satisfy different kinds of demands. Contact An Pump 24x7 service for your Syrup dispenser pump:

An pump machinery’s main products includes: slurry pump, desulfurization pump, gravel pump, mud pump, sewage pump, submersible pump, submersible sewage pump, impurity pump, large capacity split casing pump, high head multistage water pump,end suction pump, self priming pump, pump parts and ancillary equipment. which can satisfy different kinds of demands. Contact An Pump 24x7 service for your Syrup dispenser pump:  Roger Chen P: +86 311 899 40549 F: +86 311 862 71170 Office C: +86 150 3285 7866 Personal C: +86 137 805 12387 Wechat /whatsapp: +86 137 805 12387 Skype: chenroger1215 Web: www.angroupcn.com Email: roger at angroupcn.com Email: pump at angroupcn.com (Please put "@" to "at" when you send the email) Related Water Pump

Roger Chen P: +86 311 899 40549 F: +86 311 862 71170 Office C: +86 150 3285 7866 Personal C: +86 137 805 12387 Wechat /whatsapp: +86 137 805 12387 Skype: chenroger1215 Web: www.angroupcn.com Email: roger at angroupcn.com Email: pump at angroupcn.com (Please put "@" to "at" when you send the email) Related Water Pump

Product Description Syrup dispenser pump advantages 1. High efficiency, Energy saving: operation efficiency is 3-10% higher than ordinary pulp pump, energy saving to 15-30%

Product Description Syrup dispenser pump advantages 1. High efficiency, Energy saving: operation efficiency is 3-10% higher than ordinary pulp pump, energy saving to 15-30%2. Good NPSH, Long service: actual using life is twice-third time than ordinary pulp pump.

3. High concentrations, Non-clogging: transfer pulp concentration max to 6%.

4. Reasonable structure, Easy maintenance: Pump head is front, rear casing structure, when maintenance there is no need to remove pipe line, only remove the electric motor backwards, then could disassemble and repair the pump. Syrup dispenser pump introduction AJY high efficient energy saving pulp pump, with advantage from broad and domestic, we take advanced design theory to develop new type pump, hydraulic design with theory “relative suction, relative obstruction”. The pump wet parts hydraulic performance is compliance with pump flow law, then reduce the erosion and wear of wet parts by liquid. Greatly improve the pump efficiency and service life. Syrup dispenser pump Model Meaning AJY50-6FY

AJY: Pulp pump

50: Flow rate(capacity) m3/hr

6: Head(pressure) m

F: Material: stainless steel

Y: Shaft seal type: expeller dynamic seal

Pump Material: Ductile Iron(Q), Cast Steel(G), Resistant steel(N), Stainless Steel(F), Duplex Stainless Steel 316(X)

Pump Seal Type: expeller dynamic seal(Y), Single Mechanical Seal(S), Double Mechanical Seal(D) Stainless steel paper pulp pump structure A.B.C.D.E.F.G.H.M.K.N.P.R.Q.S.T.U.V.W category pulp pump main structure

Grease, oil lubrication structural parts 1.Front pump cover 3.Impeller 4. Pump casing 5. Pump cover 6. Shaft cover 7. Packing gland 8. Slinger ring 9. Front bearing cover 10. Shaft 11. Breathable cover 12. Oil flag 13. Bearing frame 14. Back bearing cover 15. Support base 16. Coupling on pump end 17. Coupling for motor end 18.Base plate 19. Electric motor 20. Couplingguard Pump Application: Syrup dispenser pump particularly applicable industry

Grease, oil lubrication structural parts 1.Front pump cover 3.Impeller 4. Pump casing 5. Pump cover 6. Shaft cover 7. Packing gland 8. Slinger ring 9. Front bearing cover 10. Shaft 11. Breathable cover 12. Oil flag 13. Bearing frame 14. Back bearing cover 15. Support base 16. Coupling on pump end 17. Coupling for motor end 18.Base plate 19. Electric motor 20. Couplingguard Pump Application: Syrup dispenser pump particularly applicable industry 1. Paper Industry: Suitable for transfer paper pulp concentration max to 6%, and liquid cycle transmission during base recovery processing, for lifting and pressing.

2. Sugar Industry: Suitable for transfer syrup max to 4%, and viscosity max 150 mm2/S.

3. Urban Sewage Treatment, Suitable for transfer sewage, waste water, for lifting and pressing Pump pictures Syrup dispenser pump pictures

Our Services Our Services 1. Offer Large capacity pump solutions

Our Services Our Services 1. Offer Large capacity pump solutions2. Selection

3. OEM available

4. ODM available

5. Design

6. Installation

7. Maintenance

Company Information Shijiazhuang An Pump Machinery Co.,Ltd is a manufacturer and trading enterprise, which is mainly engaged in pump designing, manufacturing, selling and service. We develop the international trading business of mining equipment, slurry pumps, and water pumps according the wide customer resource, comprehensive technology and reasonable staffing.

Company Information Shijiazhuang An Pump Machinery Co.,Ltd is a manufacturer and trading enterprise, which is mainly engaged in pump designing, manufacturing, selling and service. We develop the international trading business of mining equipment, slurry pumps, and water pumps according the wide customer resource, comprehensive technology and reasonable staffing.  An pump machinery’s main products includes: slurry pump, desulfurization pump, gravel pump, mud pump, sewage pump, submersible pump, submersible sewage pump, impurity pump, large capacity split casing pump, high head multistage water pump,end suction pump, self priming pump, pump parts and ancillary equipment. which can satisfy different kinds of demands. Contact An Pump 24x7 service for your Syrup dispenser pump:

An pump machinery’s main products includes: slurry pump, desulfurization pump, gravel pump, mud pump, sewage pump, submersible pump, submersible sewage pump, impurity pump, large capacity split casing pump, high head multistage water pump,end suction pump, self priming pump, pump parts and ancillary equipment. which can satisfy different kinds of demands. Contact An Pump 24x7 service for your Syrup dispenser pump:  Roger Chen P: +86 311 899 40549 F: +86 311 862 71170 Office C: +86 150 3285 7866 Personal C: +86 137 805 12387 Wechat /whatsapp: +86 137 805 12387 Skype: chenroger1215 Web: www.angroupcn.com Email: roger at angroupcn.com Email: pump at angroupcn.com (Please put "@" to "at" when you send the email) Related Water Pump

Roger Chen P: +86 311 899 40549 F: +86 311 862 71170 Office C: +86 150 3285 7866 Personal C: +86 137 805 12387 Wechat /whatsapp: +86 137 805 12387 Skype: chenroger1215 Web: www.angroupcn.com Email: roger at angroupcn.com Email: pump at angroupcn.com (Please put "@" to "at" when you send the email) Related Water Pump | End suction pump | Split casing pump | Multistage pump |

|  |  |

Related Keywords

Related Keywords