Large Capacity Centrifugal Split Casing Sea Water Pump

- Delivery Time:

- 4 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

Large Capacity Centrifugal Split Casing Sea Water Pump Application

Large Capacity Centrifugal Split Casing Sea Water Pump Application Industry | Plumbing Applications |

General water supply | Circulation of HVAC building systems , water booster service , |

Agriculture / Food / Beverage | Irrigation , water supply , food processing , beverage processing |

Manufacturing | Pulp and paper fans , plastic & rubber , metal & steel , |

Fire / Disaster Relief | Fire pumps , fire protection , flood control , disaster relief , |

Utilities : Water / Wastewater | Power Generation stations , dewatering , desalination , |

Chemical / Mining | Chemical plants , refineries , petroleum distribution , coal sites , ethylene glycol pumping . |

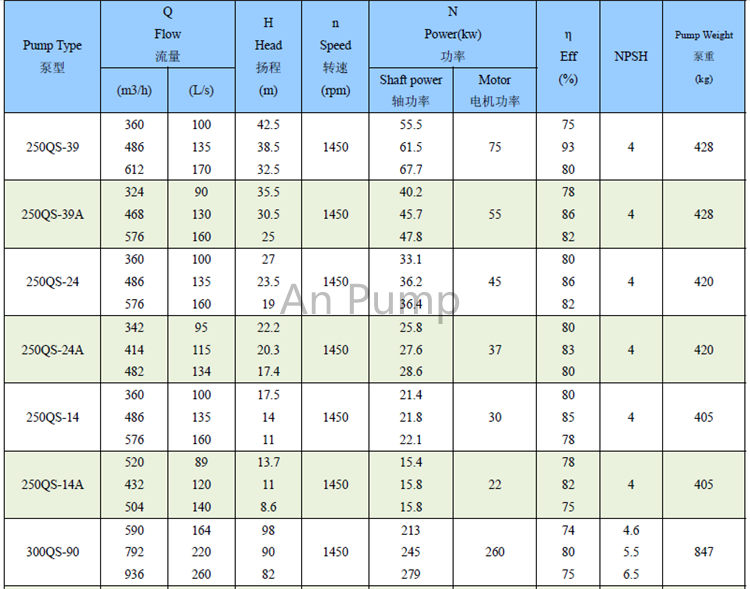

Max Q:14400m3/h Max H:140m

Max Temperature:80 Centigrade

CE/ISO Drive:Diesel engine or Motor both are ok. Material: Stainless steel, High Cr Alloy, Cast iron, Ductile cast iron, cast steel, Carbon steel, bronze QSH, QS Single-stage double suction centrifugal pumps for distribution of water and chemical substances with characteristicssimilar to that of liquid water. A medium temperature of 120 ° C. Ability to Change the seal ring, bushings and the impeller if the material contains sediment as in the case of “muddy” water. Pump seals most commonly used are soft filler seal. However, in cases of special requirements can be modified to mechanical seals, from the point of view of the electrical pump. Large Capacity Centrifugal Split Casing Sea Water Pump parameter

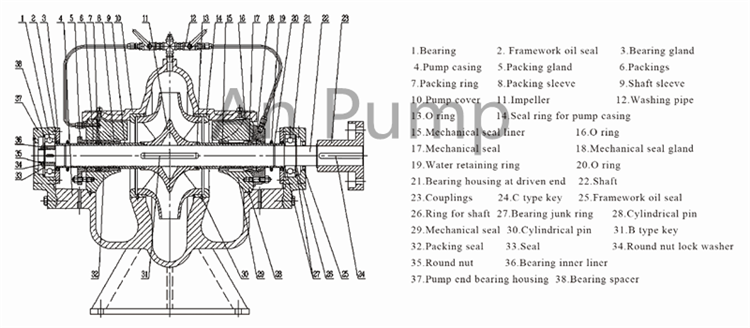

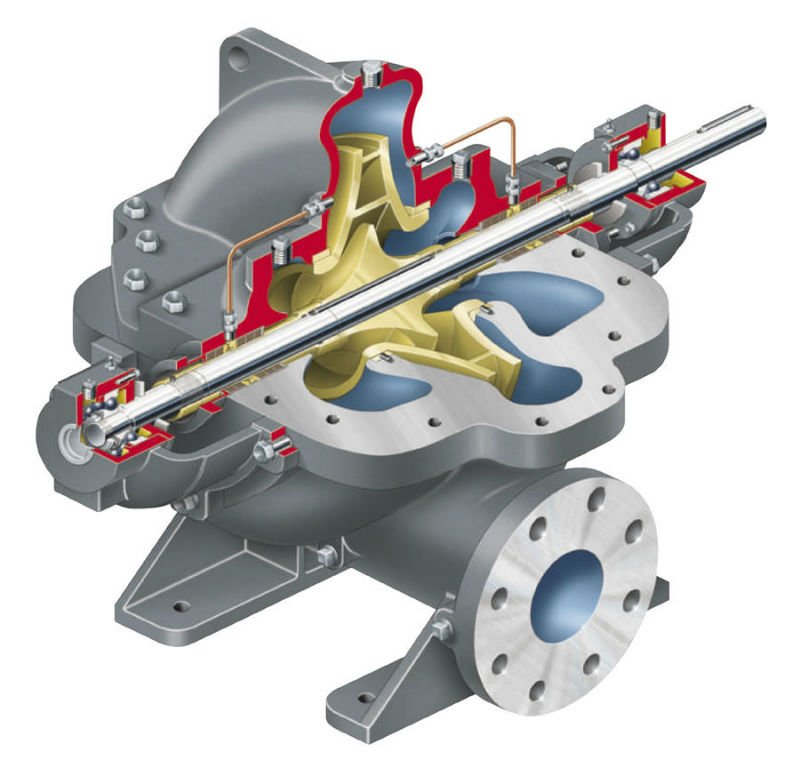

Large Capacity Centrifugal Split Casing Sea Water Pump Constructure

Large Capacity Centrifugal Split Casing Sea Water Pump Constructure

Large Capacity Centrifugal Split Casing Sea Water Pump Material 1. Pump Casing and Cover : Cast Iron GG25 ; Ductile Cast Iron GGG40 ; Cast Steel ; SS304 316 316L ; Duplex SS CD4-MCu ; Bronze 2. Pump Impeller : Cast Iron GG25 ; Ductile Cast Iron GGG40 ; Cast Steel ; SS304 316 316L ; Duplex SS CD4-MCu ; Bronze 3. Shaft : Carbon steel AISI1045 ; Chrome Steel 40Cr ; SS AISI420 ; SS AISI4140 ; SS316Ti ; SS DIN1.4571 ; Duplex SS UNS S32205 4. Seal Type : Mechanical seal , gland packing. 5. Bearing Type : Ball Rolling 6. Shaft Sleeve : Cast Steel ; SS304 316 316L ; Duplex SS CD4-MCu 7. Wearing Ring: Cast Steel ; SS304 316 316L ; Duplex SS CD4-MCu Packaging & Shipping Large Capacity Centrifugal Split Casing Sea Water Pump Packing

Large Capacity Centrifugal Split Casing Sea Water Pump Material 1. Pump Casing and Cover : Cast Iron GG25 ; Ductile Cast Iron GGG40 ; Cast Steel ; SS304 316 316L ; Duplex SS CD4-MCu ; Bronze 2. Pump Impeller : Cast Iron GG25 ; Ductile Cast Iron GGG40 ; Cast Steel ; SS304 316 316L ; Duplex SS CD4-MCu ; Bronze 3. Shaft : Carbon steel AISI1045 ; Chrome Steel 40Cr ; SS AISI420 ; SS AISI4140 ; SS316Ti ; SS DIN1.4571 ; Duplex SS UNS S32205 4. Seal Type : Mechanical seal , gland packing. 5. Bearing Type : Ball Rolling 6. Shaft Sleeve : Cast Steel ; SS304 316 316L ; Duplex SS CD4-MCu 7. Wearing Ring: Cast Steel ; SS304 316 316L ; Duplex SS CD4-MCu Packaging & Shipping Large Capacity Centrifugal Split Casing Sea Water Pump Packing

Company Information Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps type design, use and maintenance program.

Company Information Shijiazhuang An Pump Machinery Co., Ltd is a professional manufacturer of slurry pumps, sewage pumps, clean water pumps, chemical pumps, fire pumps, irrigation pumps; An Pump Machinery company has its own Kingda type selection & design, research and development team, assure to provide you efficient, energy saving slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps type design, use and maintenance program.  Strong , experienced technical personnel is the powerful guarantee for quality products of slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps. An Pump Machinery technical team set up five R & D teams: hydraulic engineering, water pump structure, new materials research and development, casting, molding etc. Except the commonly used CAD and other design software, the technical teams also use CAPP computer-aided industrial design and CFD hydraulic design software. They combine years of experience in the practical application of the products, repeated use of water conservancy GIS, MIS software and simulation analysis system software demonstrated, calculations, the theoretical calculations product of slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps are accurate and consistent with the actual performance. It allowing users to meet the needs while significantly reducing the investment costs, improves An Pump Machinery Company's strong core competitiveness. Our Services Our Services 1. Offer Large capacity sea water pump solutions

Strong , experienced technical personnel is the powerful guarantee for quality products of slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps. An Pump Machinery technical team set up five R & D teams: hydraulic engineering, water pump structure, new materials research and development, casting, molding etc. Except the commonly used CAD and other design software, the technical teams also use CAPP computer-aided industrial design and CFD hydraulic design software. They combine years of experience in the practical application of the products, repeated use of water conservancy GIS, MIS software and simulation analysis system software demonstrated, calculations, the theoretical calculations product of slurry pumps, sewage pump, water pump, chemical pumps, fire pumps, irrigation pumps are accurate and consistent with the actual performance. It allowing users to meet the needs while significantly reducing the investment costs, improves An Pump Machinery Company's strong core competitiveness. Our Services Our Services 1. Offer Large capacity sea water pump solutions2. Selection

3. OEM available

4. ODM available

5. Design

6. Installation

7. Maintenance

Contact Us Learn more , please contact us directly. Mandy Wang

Contact Us Learn more , please contact us directly. Mandy WangInternational Dept. Shijiazhuang An pump Machinery Co.,Ltd Web:www.angroupcn.com Email:coco(@)angroupcn.com Tel:86-311-89940549 Fax:86-311-86271170 WhatsApp:0086-137-3107-1183 Skype:mandy.anpump

Related Keywords