Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

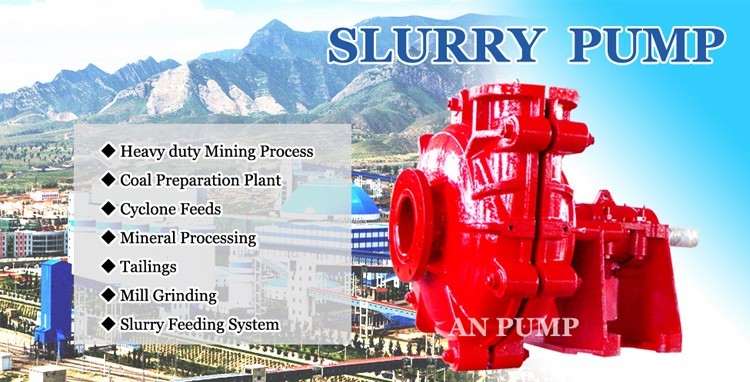

Battle Max Lime for Mining Solid Slurries Mining Slurry Pump  Product Description Detailed Description- Battle Max Lime for Mining Solid Slurries Mining Slurry Pump 1) Cantilevered, horizontal, centrifugal, one stage, single casing gravel (sand) pump 2) High head, large capacity, high efficiency. 3) Good NPSH performance. 4) Widely application: They are designed for handling more abrasive with solids slurries in the river dredging, Sand reclamation, explosive sludge in metal melting, dredging in dredger and course of river and other fields. 5) Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 6) Wear resistant wet parts: The wet parts are made of Ni hard and high chromium abrasion resistance alloys. (more than 26% Chrome alloy). 7) The frame plate for type AM pumps have replaceable wear-resistant metal liners or rubber liners. The impellers are made of wear-resistant metal or rubber. 8) Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 9) Centrifugal seal, mechanical seal and packing seal are available. 10) The shaft seals for type AM pumps may be adoptable of gland seal or expeller seal 11) The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications.

Product Description Detailed Description- Battle Max Lime for Mining Solid Slurries Mining Slurry Pump 1) Cantilevered, horizontal, centrifugal, one stage, single casing gravel (sand) pump 2) High head, large capacity, high efficiency. 3) Good NPSH performance. 4) Widely application: They are designed for handling more abrasive with solids slurries in the river dredging, Sand reclamation, explosive sludge in metal melting, dredging in dredger and course of river and other fields. 5) Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 6) Wear resistant wet parts: The wet parts are made of Ni hard and high chromium abrasion resistance alloys. (more than 26% Chrome alloy). 7) The frame plate for type AM pumps have replaceable wear-resistant metal liners or rubber liners. The impellers are made of wear-resistant metal or rubber. 8) Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 9) Centrifugal seal, mechanical seal and packing seal are available. 10) The shaft seals for type AM pumps may be adoptable of gland seal or expeller seal 11) The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications.  Battle Max Lime for Mining Solid Slurries Mining Slurry Pump On Site

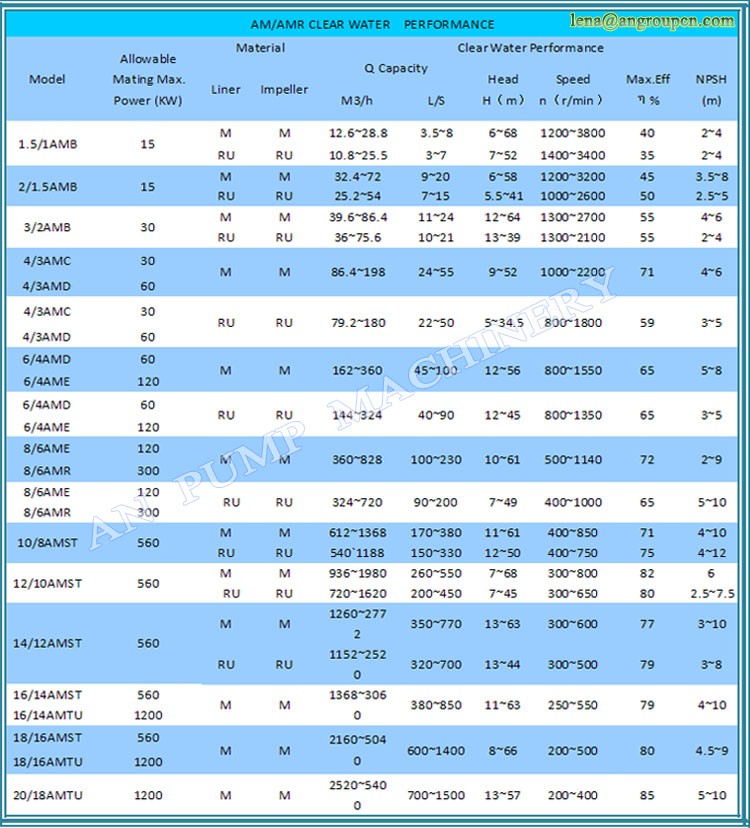

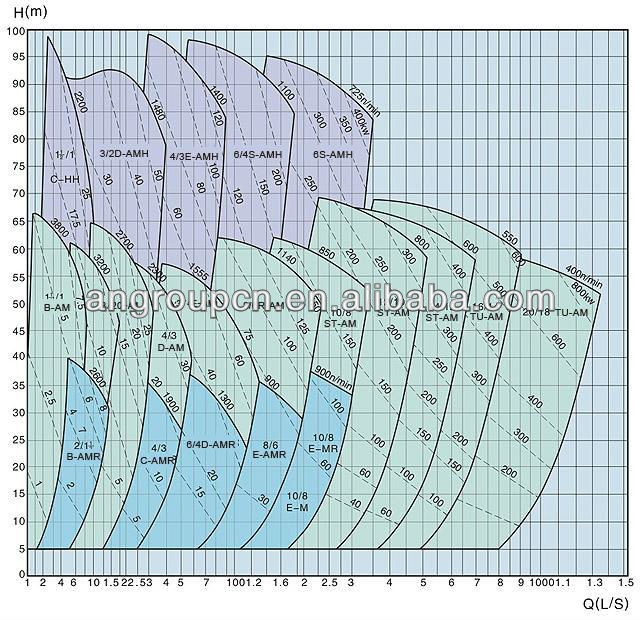

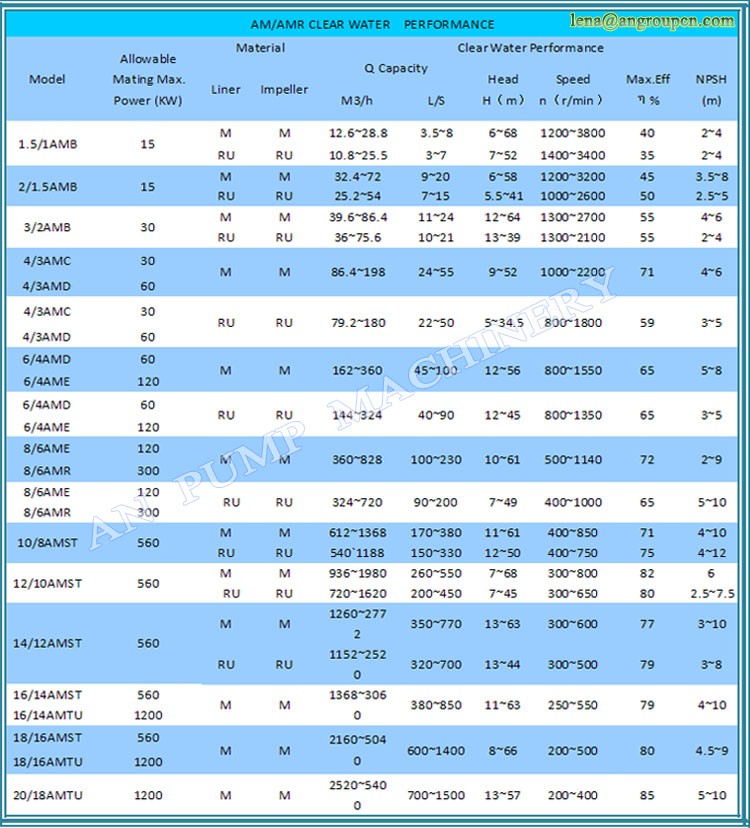

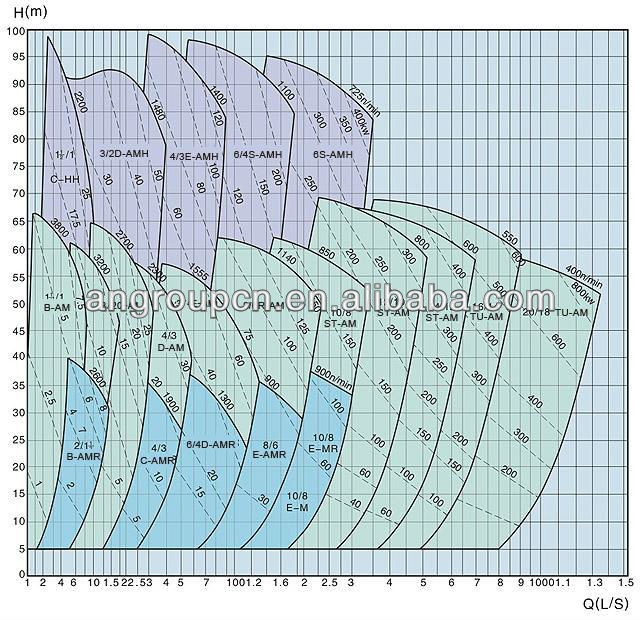

Battle Max Lime for Mining Solid Slurries Mining Slurry Pump On Site  Pump Performance Chart - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

Pump Performance Chart - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump  Pump Performance Chart - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

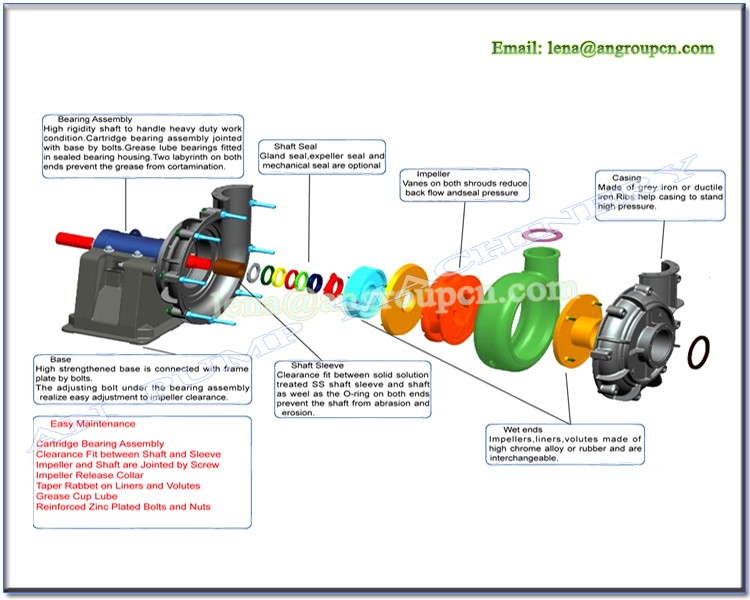

Pump Performance Chart - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump  Pump Parts - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

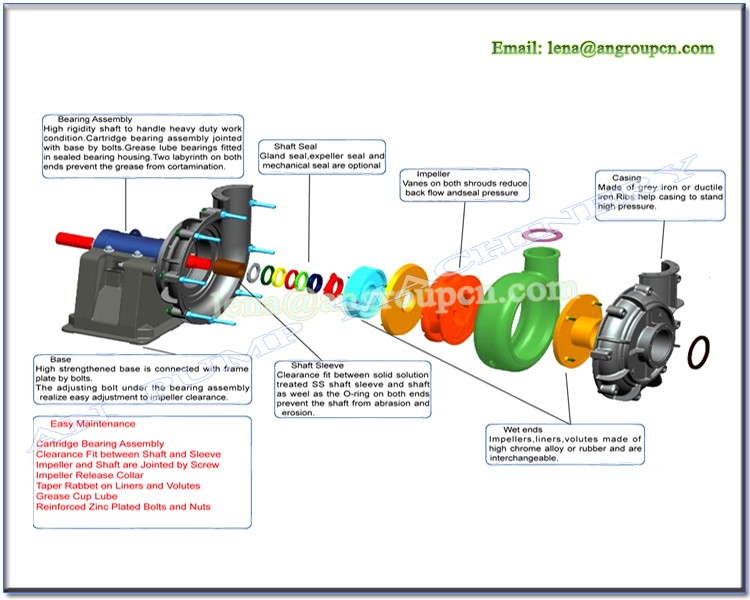

Pump Parts - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. 5. All of the rubber parts have superior erosion resisting performance which can be used for a long life. 6. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 7. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 8. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 9. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. Spare parts: Structure- Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

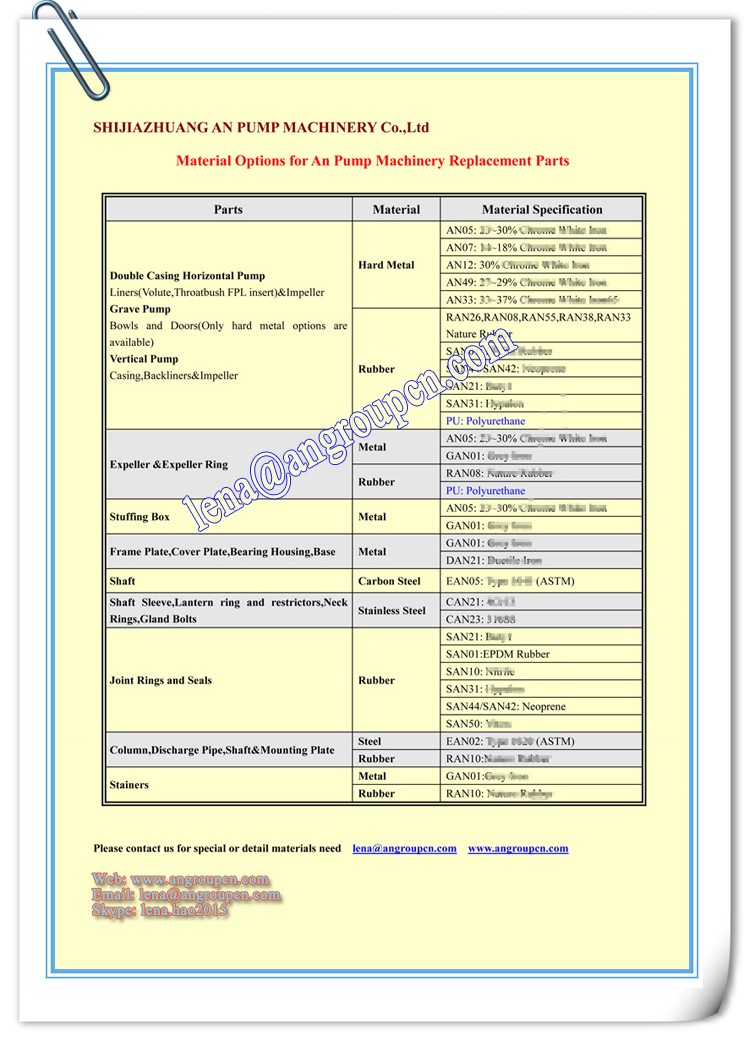

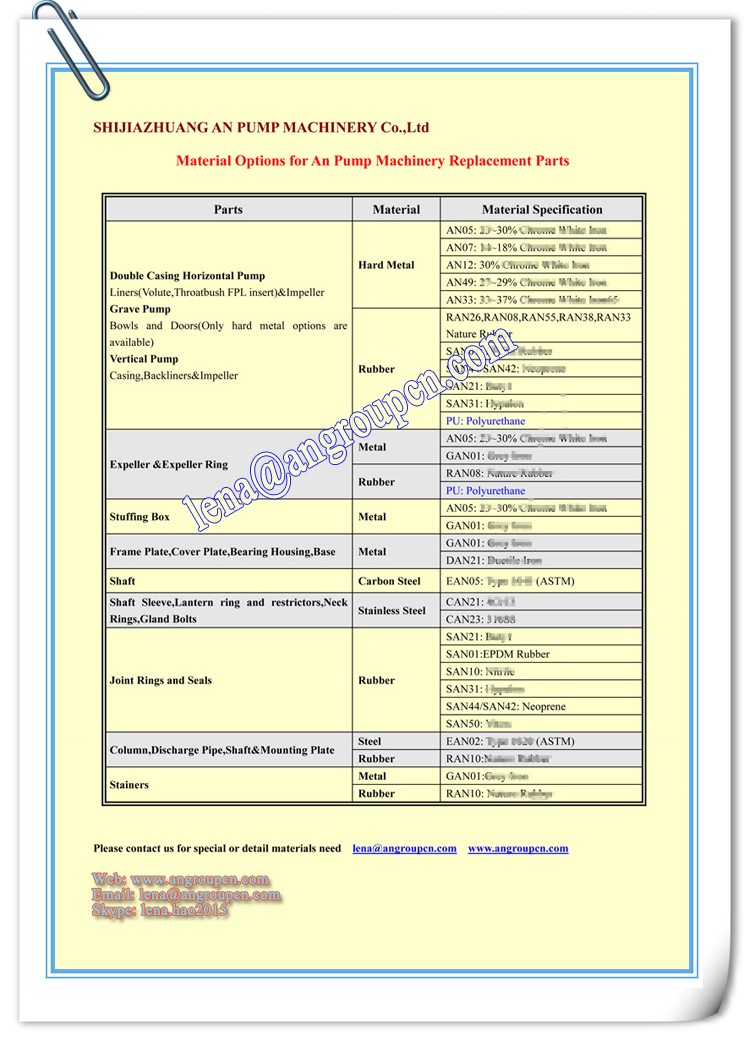

Structure- Battle Max Lime for Mining Solid Slurries Mining Slurry Pump  Materials - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

Materials - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump  Company Information

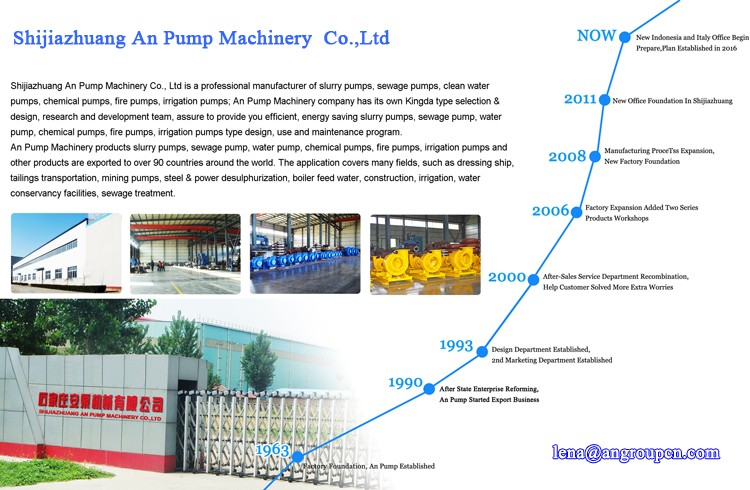

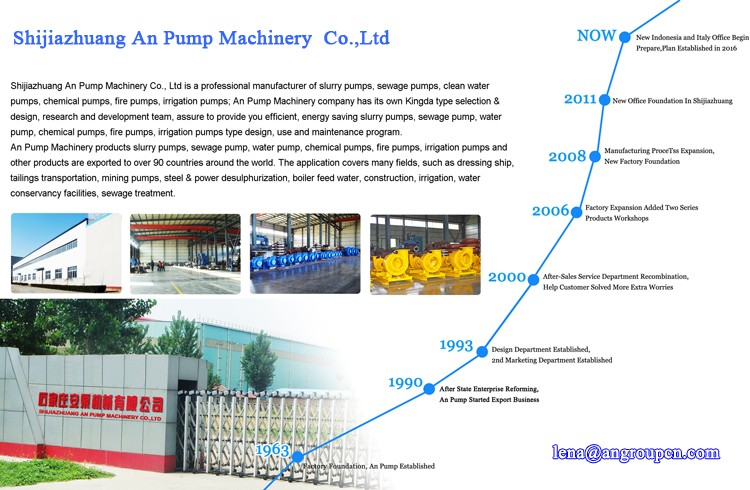

Company Information

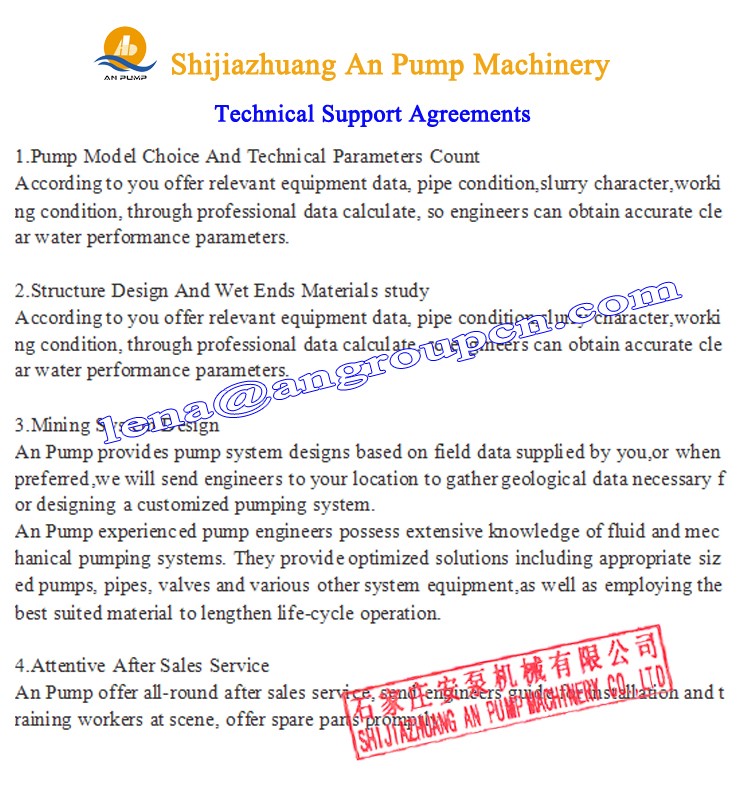

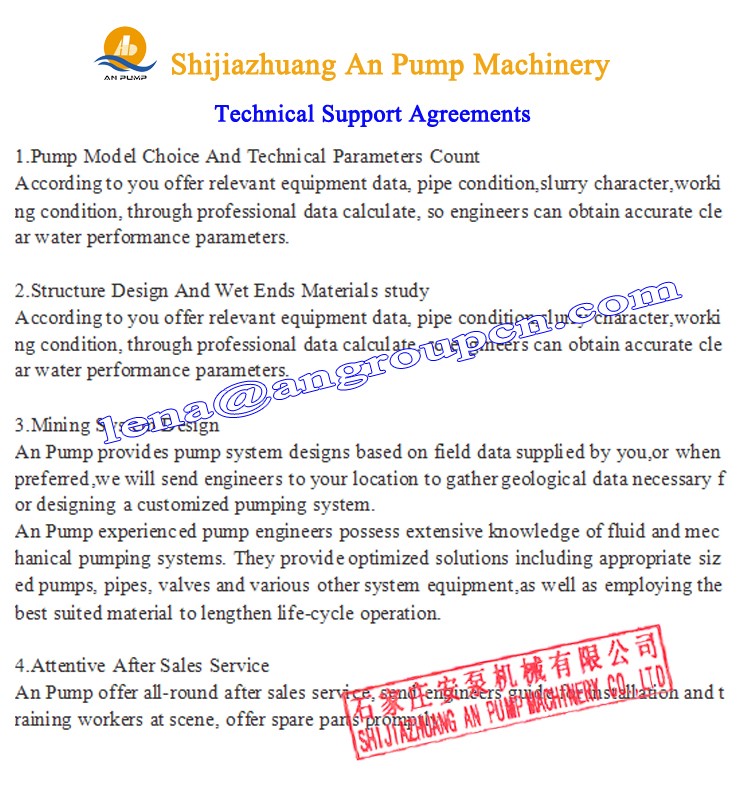

Our Services

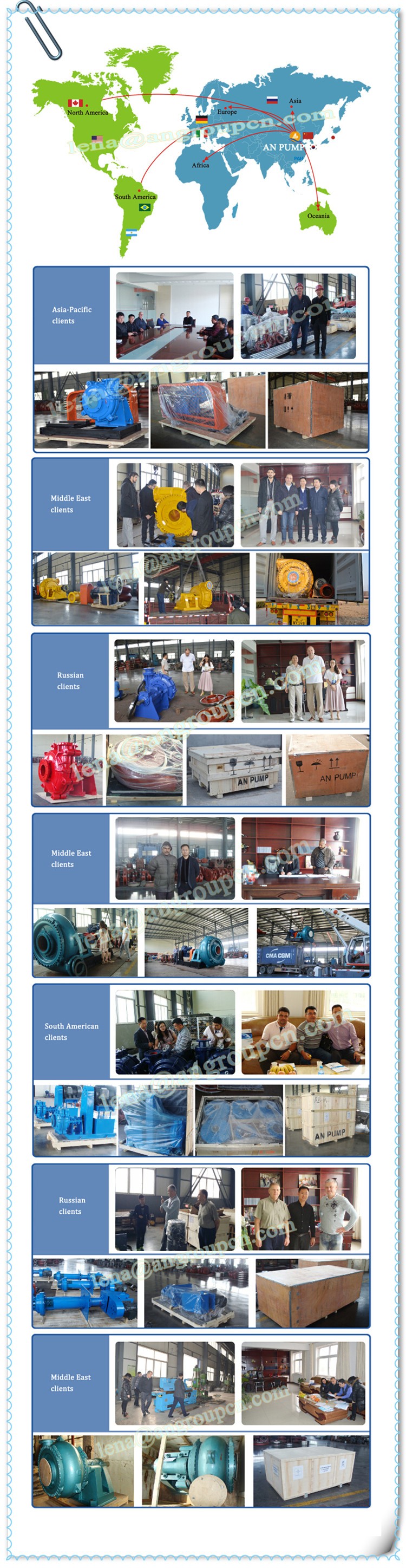

Our Services  Our Advantages You will obtain products and service advantages *About 30 years Design, produce and service experience. *Price is suitable. We are directly factory, own finished foundry model, cost only including original materials fee, machinery fee, worker fee. *Quality, our materials used high chrome, reached above 27%, 28%, wear resistant and corrosion resistant , pump use life longer. High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate *After sale service, we can offer 2 years quality guarantee, also have a very strong technical support department and special after sale service department. When you have any need future, we can sent you professional technical man to Russian help you. We also have one of group high quality technicians who can help you solve any question during the process *When received your order, we have very professional manufacture process and supervision process. For you, i also will to plant supervise manufacture and take photo for you per day in person. So can keep you do not worry. *After finish manufacture, we will test each pump. take a video and make a testing report for you. If available, you also can to our factory to supervise testing in person. *Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon *Rich export Experience. we had export USA, Germany,Canada , Australian and so on developed country and South Africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high reputation at home and abroad. Certificate, your reliable

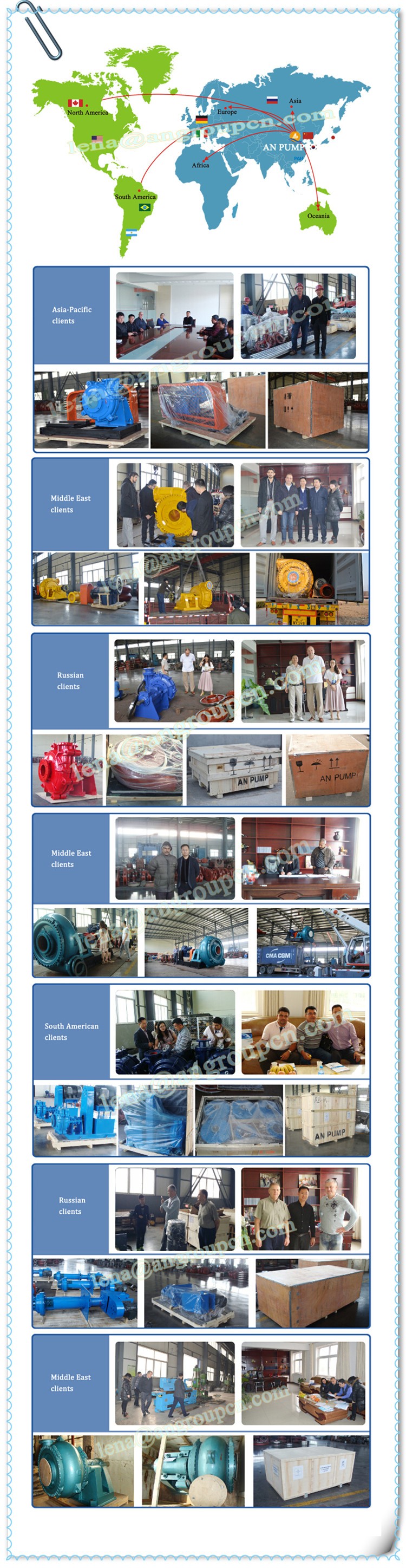

Our Advantages You will obtain products and service advantages *About 30 years Design, produce and service experience. *Price is suitable. We are directly factory, own finished foundry model, cost only including original materials fee, machinery fee, worker fee. *Quality, our materials used high chrome, reached above 27%, 28%, wear resistant and corrosion resistant , pump use life longer. High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate *After sale service, we can offer 2 years quality guarantee, also have a very strong technical support department and special after sale service department. When you have any need future, we can sent you professional technical man to Russian help you. We also have one of group high quality technicians who can help you solve any question during the process *When received your order, we have very professional manufacture process and supervision process. For you, i also will to plant supervise manufacture and take photo for you per day in person. So can keep you do not worry. *After finish manufacture, we will test each pump. take a video and make a testing report for you. If available, you also can to our factory to supervise testing in person. *Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon *Rich export Experience. we had export USA, Germany,Canada , Australian and so on developed country and South Africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high reputation at home and abroad. Certificate, your reliable  Reliable Experience Pumping word

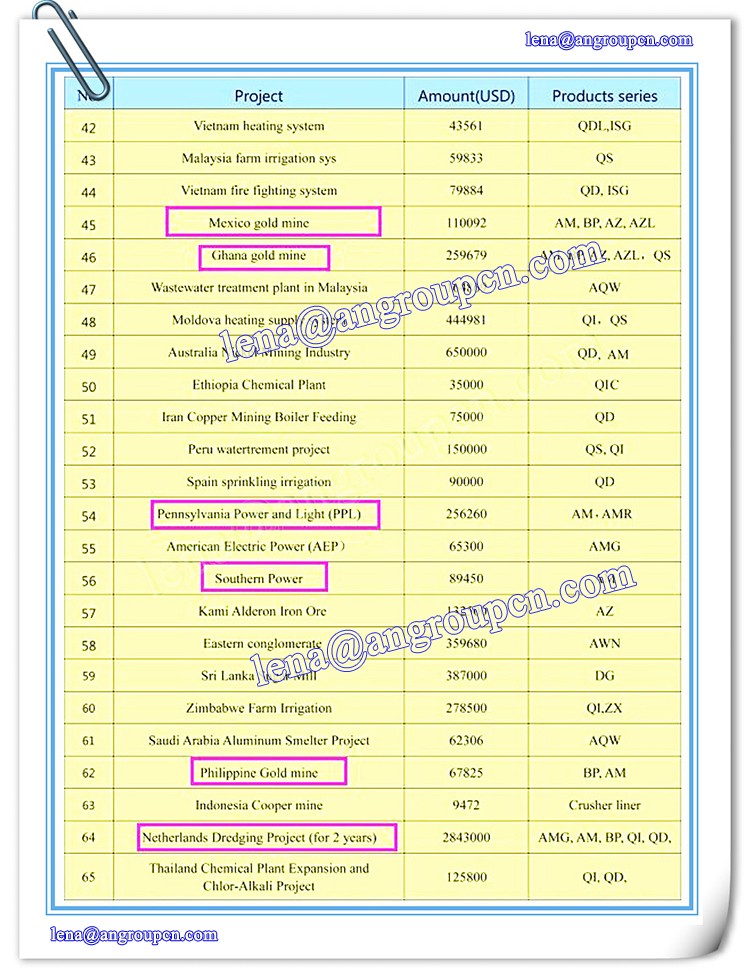

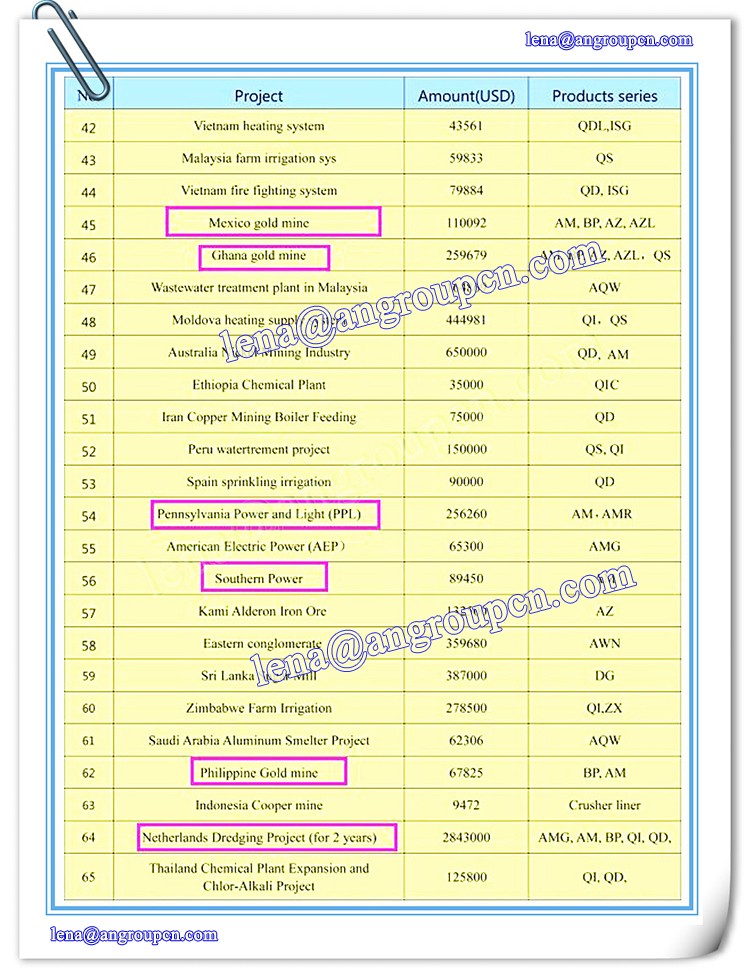

Reliable Experience Pumping word  Project contract

Project contract  Our Team

Our Team  Welcome Contact Us Lena Hao

Welcome Contact Us Lena Hao

Internation Trade Manager WhasApp:+8618732129616

Skype:anpump-lena

Email:lena(at)angroupcn.com

Web:www.angroupcn.com

Product Description Detailed Description- Battle Max Lime for Mining Solid Slurries Mining Slurry Pump 1) Cantilevered, horizontal, centrifugal, one stage, single casing gravel (sand) pump 2) High head, large capacity, high efficiency. 3) Good NPSH performance. 4) Widely application: They are designed for handling more abrasive with solids slurries in the river dredging, Sand reclamation, explosive sludge in metal melting, dredging in dredger and course of river and other fields. 5) Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 6) Wear resistant wet parts: The wet parts are made of Ni hard and high chromium abrasion resistance alloys. (more than 26% Chrome alloy). 7) The frame plate for type AM pumps have replaceable wear-resistant metal liners or rubber liners. The impellers are made of wear-resistant metal or rubber. 8) Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 9) Centrifugal seal, mechanical seal and packing seal are available. 10) The shaft seals for type AM pumps may be adoptable of gland seal or expeller seal 11) The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications.

Product Description Detailed Description- Battle Max Lime for Mining Solid Slurries Mining Slurry Pump 1) Cantilevered, horizontal, centrifugal, one stage, single casing gravel (sand) pump 2) High head, large capacity, high efficiency. 3) Good NPSH performance. 4) Widely application: They are designed for handling more abrasive with solids slurries in the river dredging, Sand reclamation, explosive sludge in metal melting, dredging in dredger and course of river and other fields. 5) Long bearing life: The bearing assembly is with large diameter shaft and short overhang. 6) Wear resistant wet parts: The wet parts are made of Ni hard and high chromium abrasion resistance alloys. (more than 26% Chrome alloy). 7) The frame plate for type AM pumps have replaceable wear-resistant metal liners or rubber liners. The impellers are made of wear-resistant metal or rubber. 8) Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing. 9) Centrifugal seal, mechanical seal and packing seal are available. 10) The shaft seals for type AM pumps may be adoptable of gland seal or expeller seal 11) The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications.  Battle Max Lime for Mining Solid Slurries Mining Slurry Pump On Site

Battle Max Lime for Mining Solid Slurries Mining Slurry Pump On Site  Pump Performance Chart - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

Pump Performance Chart - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump  Pump Performance Chart - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

Pump Performance Chart - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump  Pump Parts - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

Pump Parts - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump 1. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 2. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 3. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 4. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. 5. All of the rubber parts have superior erosion resisting performance which can be used for a long life. 6. All of the metal wet parts can are made of high chromium alloy which has superior wear and erosion resistance or grey iron which has a high rigidity. 7. As the expeller ring is assembled together with the expeller, much pressure can be reduced effectively for the impeller. Meanwhile, it can still maintain a reliable sealing performance. 8. The parts such as labyrinth, labyrinth locknut, end cover and shaft sleeve are used for bearing assembly; these parts can be changed easily and have high accuracy and longer service life. 9. Some fastening parts such as studs and bolts can be used for fixing the other parts securely. All the fastening parts can be attached easily, ensuring the safety. Spare parts:

Structure- Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

Structure- Battle Max Lime for Mining Solid Slurries Mining Slurry Pump  Materials - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump

Materials - Battle Max Lime for Mining Solid Slurries Mining Slurry Pump  Company Information

Company Information

Our Services

Our Services  Our Advantages You will obtain products and service advantages *About 30 years Design, produce and service experience. *Price is suitable. We are directly factory, own finished foundry model, cost only including original materials fee, machinery fee, worker fee. *Quality, our materials used high chrome, reached above 27%, 28%, wear resistant and corrosion resistant , pump use life longer. High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate *After sale service, we can offer 2 years quality guarantee, also have a very strong technical support department and special after sale service department. When you have any need future, we can sent you professional technical man to Russian help you. We also have one of group high quality technicians who can help you solve any question during the process *When received your order, we have very professional manufacture process and supervision process. For you, i also will to plant supervise manufacture and take photo for you per day in person. So can keep you do not worry. *After finish manufacture, we will test each pump. take a video and make a testing report for you. If available, you also can to our factory to supervise testing in person. *Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon *Rich export Experience. we had export USA, Germany,Canada , Australian and so on developed country and South Africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high reputation at home and abroad. Certificate, your reliable

Our Advantages You will obtain products and service advantages *About 30 years Design, produce and service experience. *Price is suitable. We are directly factory, own finished foundry model, cost only including original materials fee, machinery fee, worker fee. *Quality, our materials used high chrome, reached above 27%, 28%, wear resistant and corrosion resistant , pump use life longer. High products quality, All our pump material is wear-resistant high Chrome alloy or nature rubber. All our products Pass ISO9001:2008 and CE certificate *After sale service, we can offer 2 years quality guarantee, also have a very strong technical support department and special after sale service department. When you have any need future, we can sent you professional technical man to Russian help you. We also have one of group high quality technicians who can help you solve any question during the process *When received your order, we have very professional manufacture process and supervision process. For you, i also will to plant supervise manufacture and take photo for you per day in person. So can keep you do not worry. *After finish manufacture, we will test each pump. take a video and make a testing report for you. If available, you also can to our factory to supervise testing in person. *Fast Delivery: For pump standard parts, we have large stock, so we can arrange delivery very soon *Rich export Experience. we had export USA, Germany,Canada , Australian and so on developed country and South Africa, Southeast Asia,south America, North America, Russia and so on many country. our products get high reputation at home and abroad. Certificate, your reliable  Reliable Experience Pumping word

Reliable Experience Pumping word  Project contract

Project contract  Our Team

Our Team  Welcome Contact Us Lena Hao

Welcome Contact Us Lena HaoInternation Trade Manager WhasApp:+8618732129616

Skype:anpump-lena

Email:lena(at)angroupcn.com

Web:www.angroupcn.com

Related Keywords

Related Keywords