Top Quality High Efficiency For Irrigation Seawater irrigation water pump

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description Description - High Efficiency For Irrigation Seawater irrigation water pump |

Working Principle: | Double suction, Split case |

Main applications: | Water |

Driver: | Electric motor, Diesel Engine |

Power Specs: | 220/380/400/415V/6KV/10KV, etc 3phase;50hz/60hz |

Max.permissible fluid temperature: | 80°C(176°F) |

Type of connection: | Flange |

Installation position: | Horizontal |

Casing parts material: | Cast iron, Stainless Steel |

Shaft seal type: | Mechanical seal ,Gland packing |

Free passage: | 1mm |

Maximum drive rating: | 1600KW(2150HP) |

Maximum caliber: | 800mm(32inch) |

Maximum head: | 125m(410ft) |

Maximum discharge-side pressure: | 1.25MPa(12.5bar) |

Flow rate range: | 133-12000m3/h(585.2-24200US.GPM) |

Application - High Efficiency For Irrigation Seawater irrigation water pump |

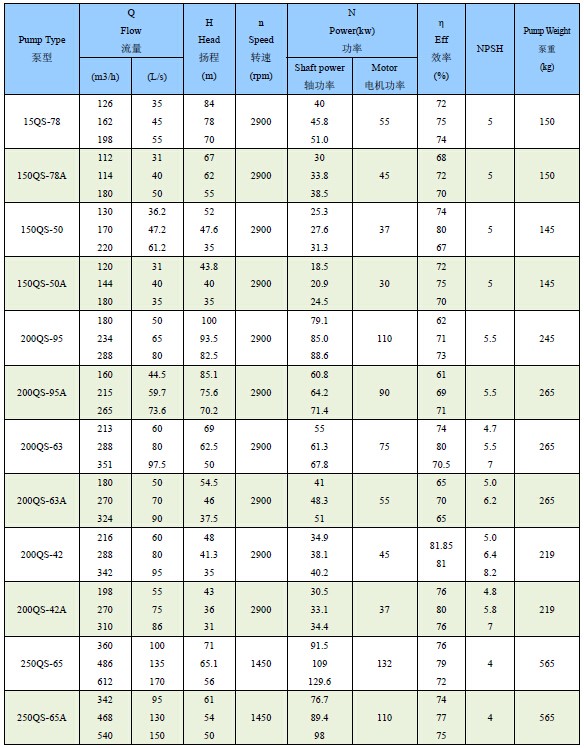

Performance Chart- High Efficiency For Irrigation Seawater irrigation water pump |

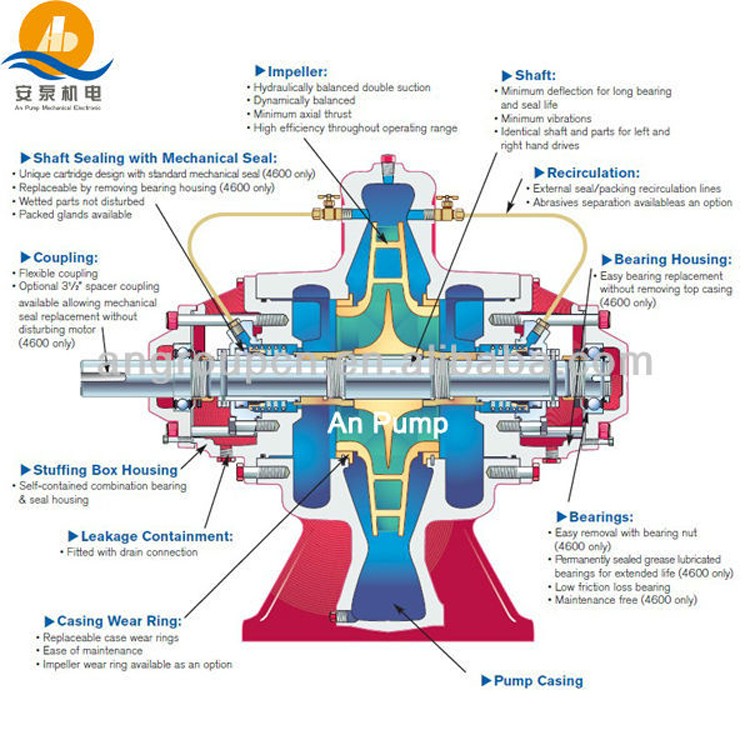

Structure Show- High Efficiency For Irrigation Seawater irrigation water pump |

1. Both inlet and outlet of this pump are placed under the axial line, horizontally and vertical to the axial line, the

1. Both inlet and outlet of this pump are placed under the axial line, horizontally and vertical to the axial line, thepump casing is opened in the middle so it is unneccessary to remove the water inlet and outlet

pipelines and motor(or other prime movers). The pump moves CW viewing from the clutch to it. The pump

moving CCW can also be made, but it should be specially noted at order.

2. The main parts of the pump are: pump casing, pump cover , impeller , shaft, dual-suction seal ring, muff,

bearing etc. and all of them, except the axle which is made of quality carbon steel, are made of cast iron. The

material may be replaced with others upon different media.

3. The volute casing is split on the horizontal centerline with the suction and discharge nozzle cast integral with

the pump casing. The upper casing is accurately located on the lower half by the use of dowel pins. The upper

casing can be removed to inspect the interior of the pump without disturbing the pipe connections or pump

alignment. The suction and discharge flanges contain tapped holes for vacuum and pressure gauge. At the

bottom of the flanges, there are tapped plugs for water drainage.

4. The impeller is static-balance calibrated, fixed with the muff and the muff nuts in both sides and its axial position

can be adjusted via the nuts and axial force gets balanced by means of the symmetrical arrangement of its blades,

there may be residual axial force which is borne by the bearing at the axle end.

5. The pump shaft is supported by two single-column centripetal ball bearings, which are mounted inside of the

bearing body on both ends of the pump and lubricated with grease. The dual-suction seal ring is used to reduce

the leak at the impeller. 6. The flexible couplings connect the pump with the motor directly. For pumps driven by belt, there must be an

intermediate bracket fitted for supporting the belt pulley.

8. The close running fit between the wearing rings and the impeller minimizes the leakage of water back into the

suction part. The rings protect the casing from wearing and can be promptly replaced with the spare parts when

they have been worn out.

9.The shaft seal is soft packing. The stuffing ring is fit between the packing in order to prevent air from leaking

into the pump and to cool and lubricate sealing case, and while the pump is working, a small amount of

high-pressured water flows into the packing case through the concave notch on the pump cover to function as

water seal. 10. The appropriate leakage from the packing case is at 10 to 20 drops per minute. Company Information

Company Long Profile |

slurry pump,

gravel pump,

desulfurization pump,

sewage pump, pulp pump,

Single stage single suction centrifugal water pump

Multistage centrifugal water pump

Split casing centrifugal water pump

Irrigation pump

Fire fighting pump

submeisible sewage pump

pipeline pump

In order to handel the the heavy duty works and satisfy different condition, we have developed our material: increased the chrome percentage from basis of 27% Cr, and added some rare metals after tested; Natural rubber develope tosynthetic rubber, polyurethane; and stainless steel to duplex stainless steel.

We are always insisting on high quality and perfect after-sale service. Our slurry pump have max three-year warranty with lifelong after-sale service. "An Pump is becoming one symbol of quality and reliability in industrial pump area."

We will keep running to satisfy more customers' requirements. Customer satisfaction is our eternal pursuit of goals, look forward to working with you to create the brilliancy together!

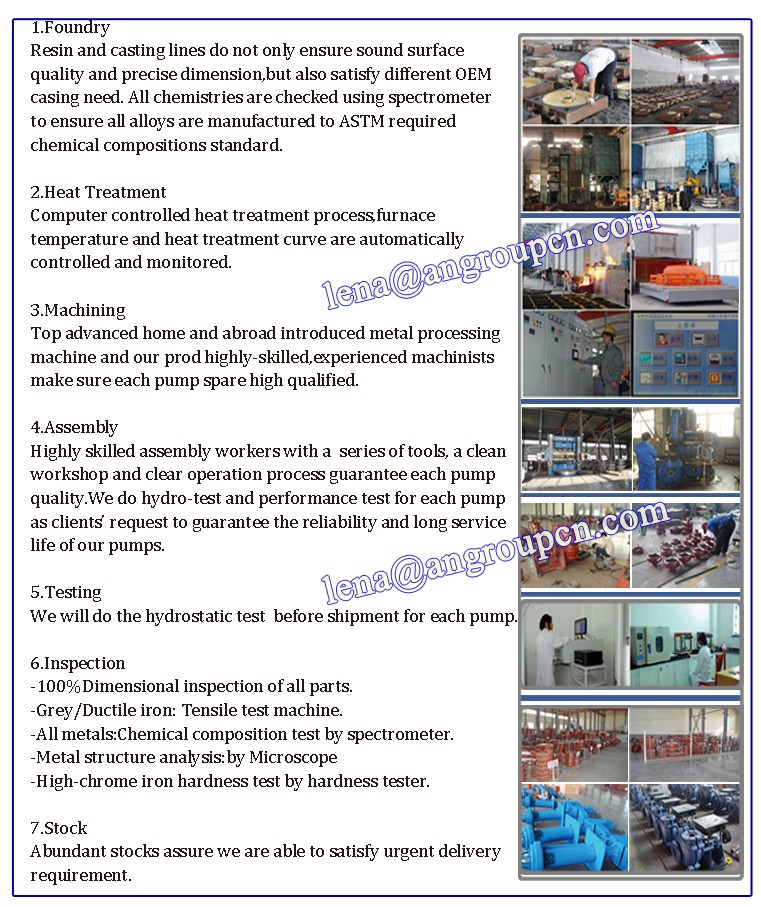

Factory Show |

Our Advantages

Our Advantages You Will Obtain High Technical Support |

You Will Obtain Products And Service Advantages |

Certificate, Your Reliable |

Reliable Experience

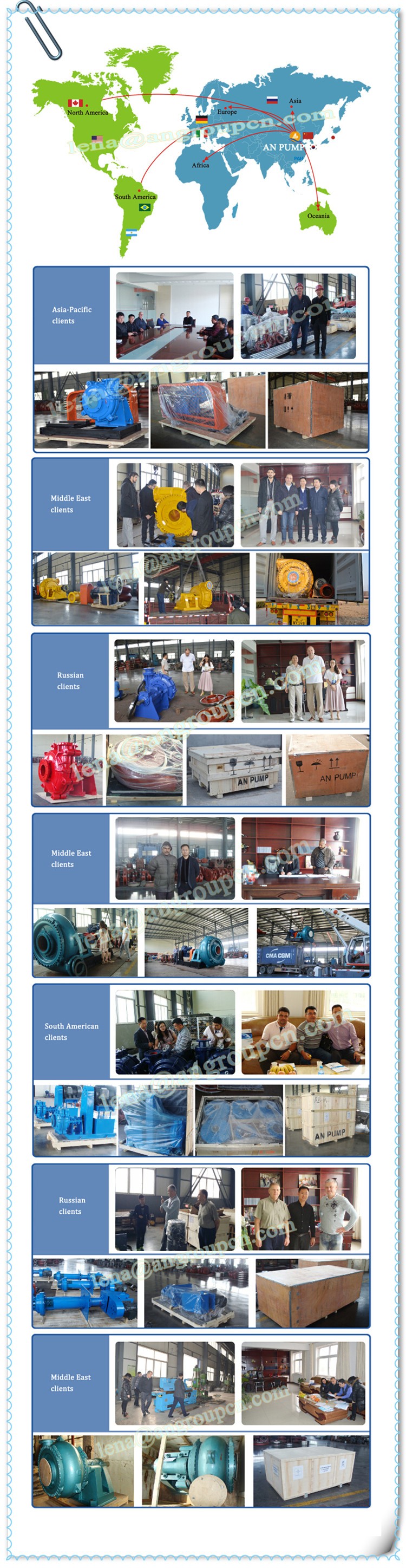

Reliable Experience Pumping Word |

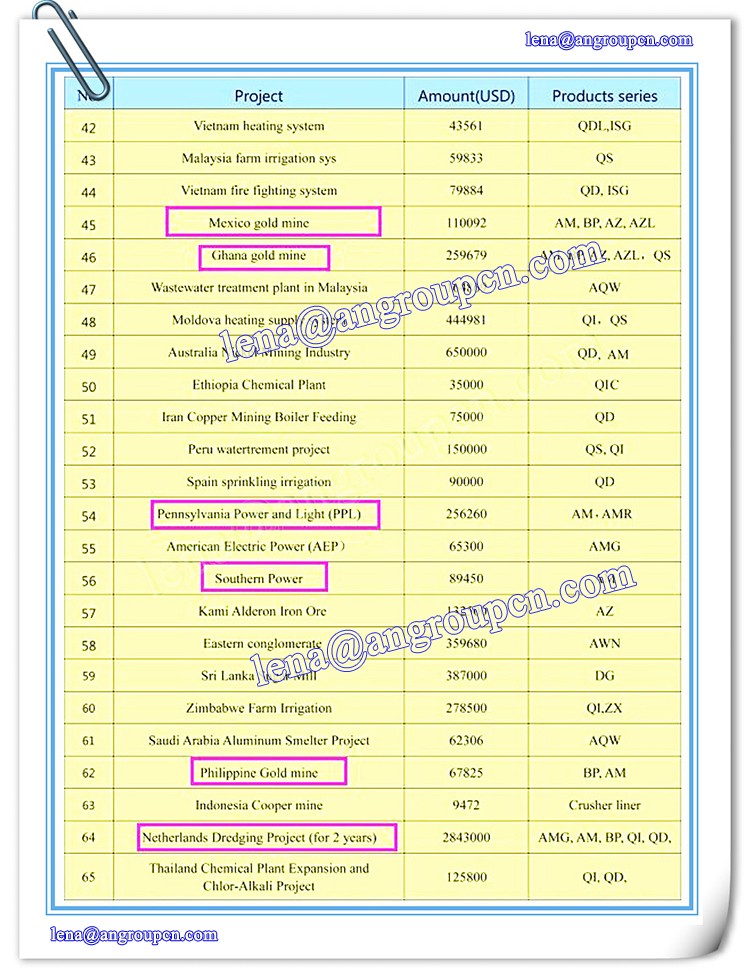

Project Contract |

Our Team

Welcome Contact Us

Welcome Contact Us  SHIJIAZHUANG AN PUMP MACHINERY CO.,LTD

SHIJIAZHUANG AN PUMP MACHINERY CO.,LTDLena Hao (CEO For International Trade)

Email: lena(@)angroupcn.com

Skype: lena.hao2015

web: www.angroupcn.com /www.waterpumpcn.com

Related Keywords