2ton travelling grate stoker steam boiler for plywood industry

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

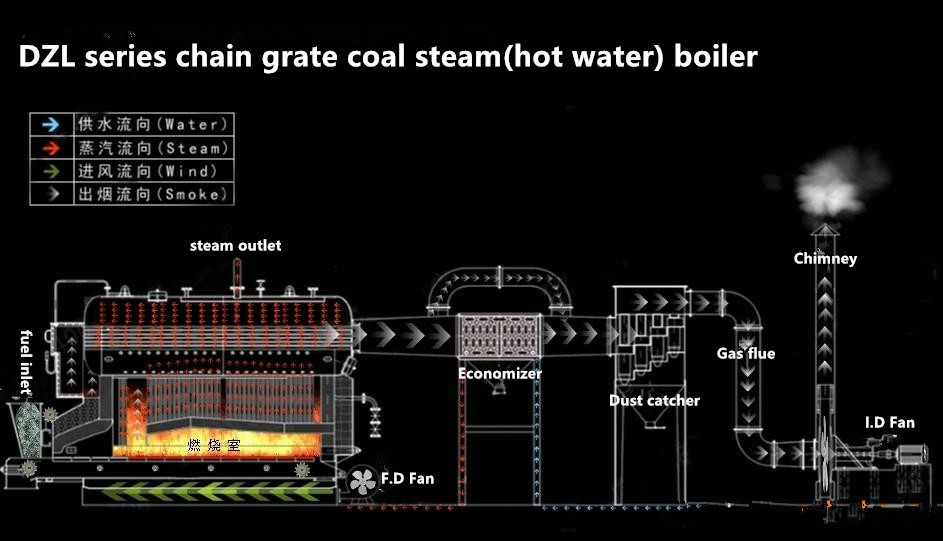

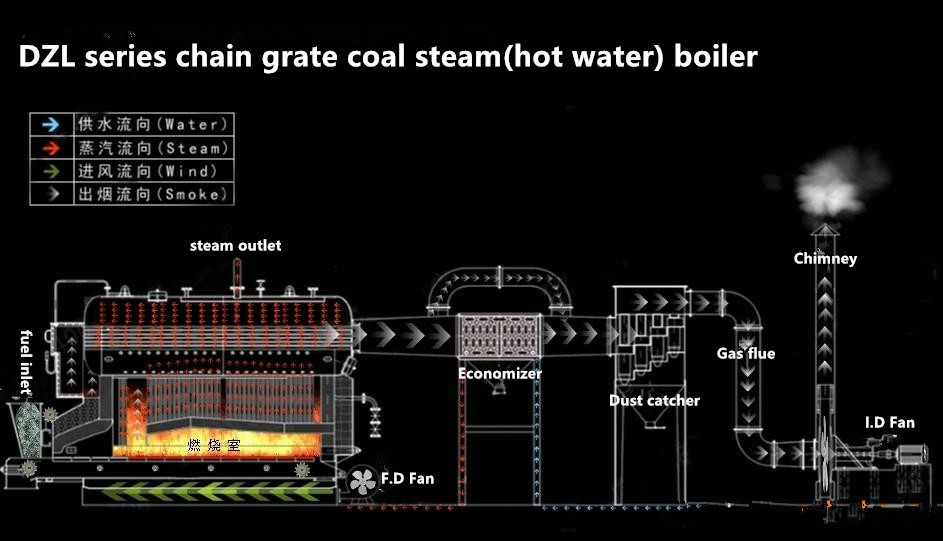

2ton travelling grate stoker steam boiler for plywood industry Product descpription DZL steam boiler General features of the coal fired horizontal steam boiler : Low pressure, horizontal, industrial, coal fired, fire tube, automatic chain grate steam boiler. The rated evaporation is between 1ton/hr to 20 ton/hr.  Product advantage: 1. Spirally corrugated tube Function: (1) Heat transfer enhancement; (2) Improve the suppleness to avoid the tube plate cracking; (3) Clean groove itself. 2. Arched tube plate Function: (1) reduce the thermal stress of weld; (2) improve the tube plate suppleness; (3) simplify the structure and save the boiler room space. 3. Complete protection device Function: deal with the situation of overpressure, over-temperature, water shortage and flameout. 4. Up-tube layout Function: (1) Avoid the bulging on boiler drum; (2) Promote the water cycle (3)clean the sediment in the boiler bottom. 5. Airfoil flue Function: Lower the high temperature of tube plate flue gas. And then reduce the thermal load of the boiler bottom.

Product advantage: 1. Spirally corrugated tube Function: (1) Heat transfer enhancement; (2) Improve the suppleness to avoid the tube plate cracking; (3) Clean groove itself. 2. Arched tube plate Function: (1) reduce the thermal stress of weld; (2) improve the tube plate suppleness; (3) simplify the structure and save the boiler room space. 3. Complete protection device Function: deal with the situation of overpressure, over-temperature, water shortage and flameout. 4. Up-tube layout Function: (1) Avoid the bulging on boiler drum; (2) Promote the water cycle (3)clean the sediment in the boiler bottom. 5. Airfoil flue Function: Lower the high temperature of tube plate flue gas. And then reduce the thermal load of the boiler bottom.  Product feature 1. Low coal consumption and High thermal efficiency; 2. Reasonable water cycling, large water capacity and spacious steam volume; 3. Equipped with light chain belt assembly grate, blowing machine and draught fan. 4. High automation, mechanical adjustment of water supply, high and low water level alarm; 5. Low water and blowers interlocking protection; 6. Mechanical operation of boiler coaling, slag discharging; 7. Simple operation and quick installation.

Product feature 1. Low coal consumption and High thermal efficiency; 2. Reasonable water cycling, large water capacity and spacious steam volume; 3. Equipped with light chain belt assembly grate, blowing machine and draught fan. 4. High automation, mechanical adjustment of water supply, high and low water level alarm; 5. Low water and blowers interlocking protection; 6. Mechanical operation of boiler coaling, slag discharging; 7. Simple operation and quick installation.  Technical parameters

Technical parameters

The fuels---biomass pellets:

Accessories

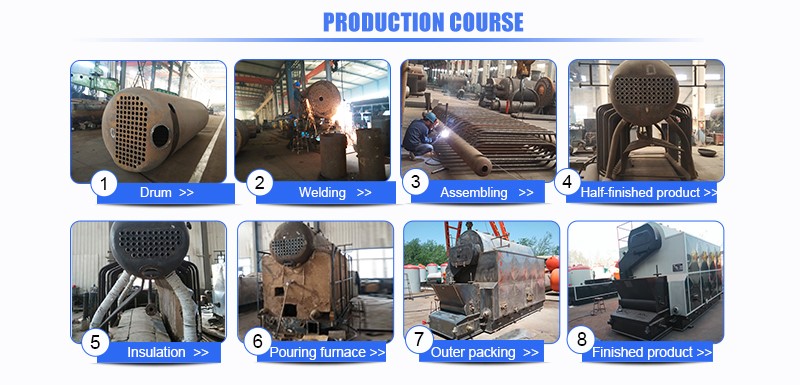

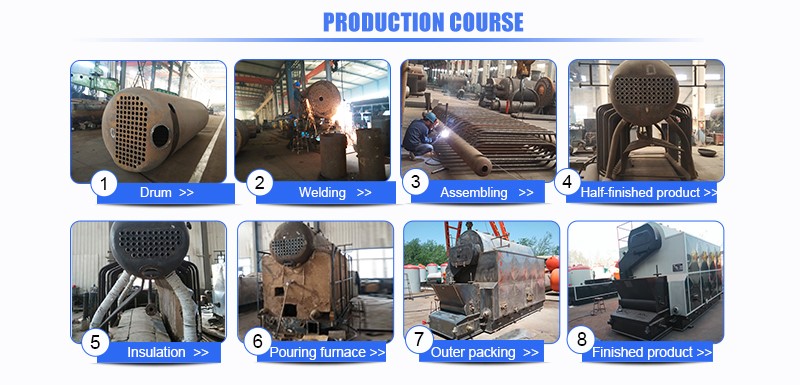

Accessories  production courses

production courses  Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Our Services Pre-sale service:

Our Services Pre-sale service:

1.According to the customer needs to recommend relative models machine.

2. According to the customer's special requirements to customize equipments.

3. Our engineers will supply the site and equipment drawing. After-sale service:

1. According to the purchase contract, our company can send engineers to help installation.

2. The quality guarantee is 1 year, not including the wearing parts.

3. Collecting customer feedback, solve the real problems faced by customers.

4. Our company supply spare parts all the year round. Besides, in the manufacturing process, clients are quite welcome to our factory to examine the actual quality and to carry out the follow-up inspection. customers Exhibition Customers: Factory Visiting Customers

Factory Visiting Customers  Certifications

Certifications  If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel: +86-18630196461 Email: linda at bangziboiler.com

If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel: +86-18630196461 Email: linda at bangziboiler.com

Product advantage: 1. Spirally corrugated tube Function: (1) Heat transfer enhancement; (2) Improve the suppleness to avoid the tube plate cracking; (3) Clean groove itself. 2. Arched tube plate Function: (1) reduce the thermal stress of weld; (2) improve the tube plate suppleness; (3) simplify the structure and save the boiler room space. 3. Complete protection device Function: deal with the situation of overpressure, over-temperature, water shortage and flameout. 4. Up-tube layout Function: (1) Avoid the bulging on boiler drum; (2) Promote the water cycle (3)clean the sediment in the boiler bottom. 5. Airfoil flue Function: Lower the high temperature of tube plate flue gas. And then reduce the thermal load of the boiler bottom.

Product advantage: 1. Spirally corrugated tube Function: (1) Heat transfer enhancement; (2) Improve the suppleness to avoid the tube plate cracking; (3) Clean groove itself. 2. Arched tube plate Function: (1) reduce the thermal stress of weld; (2) improve the tube plate suppleness; (3) simplify the structure and save the boiler room space. 3. Complete protection device Function: deal with the situation of overpressure, over-temperature, water shortage and flameout. 4. Up-tube layout Function: (1) Avoid the bulging on boiler drum; (2) Promote the water cycle (3)clean the sediment in the boiler bottom. 5. Airfoil flue Function: Lower the high temperature of tube plate flue gas. And then reduce the thermal load of the boiler bottom.  Product feature 1. Low coal consumption and High thermal efficiency; 2. Reasonable water cycling, large water capacity and spacious steam volume; 3. Equipped with light chain belt assembly grate, blowing machine and draught fan. 4. High automation, mechanical adjustment of water supply, high and low water level alarm; 5. Low water and blowers interlocking protection; 6. Mechanical operation of boiler coaling, slag discharging; 7. Simple operation and quick installation.

Product feature 1. Low coal consumption and High thermal efficiency; 2. Reasonable water cycling, large water capacity and spacious steam volume; 3. Equipped with light chain belt assembly grate, blowing machine and draught fan. 4. High automation, mechanical adjustment of water supply, high and low water level alarm; 5. Low water and blowers interlocking protection; 6. Mechanical operation of boiler coaling, slag discharging; 7. Simple operation and quick installation.  Technical parameters

Technical parameters | Project | Unit | Dzl1-0.7 | Dzl2-1.0 | Dzl-4-1.25 | Dzl6-1.25 | Dzl10-1.25 | Dzl15-1.25 |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 |

| rated steam pressure | MPa | 0.7 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| nominal steam temperature | ℃ | 170 | 183 | 194 | 194 | 194 | 194 |

| Rated inlet water temperature | ℃ | 20 | 20 | 20 | 20 | 20 | 60 |

| heating area | m² | 30.5 | 64.2 | 128 | 190.4 | 364.6 | 594.9 |

| Active grate area | m² | 2 | 3.6 | 5.29 | 7.37 | 12.67 | 16.11 |

| fuel | coal, biomass, pellets, biomass pellets, wood pellets, wood chips, sawdust, rice husk, solid fuel, dual fuel, multi fuel...etc | ||||||

| coal consumption | kg/h | 191.5 | 388 | 780 | 1155 | 1890 | 2250 |

| Exhaust gas temperature | ℃ | 158 | 167.5 | 165.5 | 166 | 156.7 | 153.5 |

| Design efficiency | % | 78.9 | 78.1 | 78 | 79 | 79.8 | 80.4 |

| Max transportation weight | t | 15 | 19.5 | 30.5 | 37.5 | 72 | 61 |

Accessories

Accessories  production courses

production courses  Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Our Services Pre-sale service:

Our Services Pre-sale service:1.According to the customer needs to recommend relative models machine.

2. According to the customer's special requirements to customize equipments.

3. Our engineers will supply the site and equipment drawing. After-sale service:

1. According to the purchase contract, our company can send engineers to help installation.

2. The quality guarantee is 1 year, not including the wearing parts.

3. Collecting customer feedback, solve the real problems faced by customers.

4. Our company supply spare parts all the year round. Besides, in the manufacturing process, clients are quite welcome to our factory to examine the actual quality and to carry out the follow-up inspection. customers Exhibition Customers:

Factory Visiting Customers

Factory Visiting Customers  Certifications

Certifications  If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel: +86-18630196461 Email: linda at bangziboiler.com

If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel: +86-18630196461 Email: linda at bangziboiler.com You May Also Like

You May Also Like