3 ton biomass steam boiler for garment industry

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

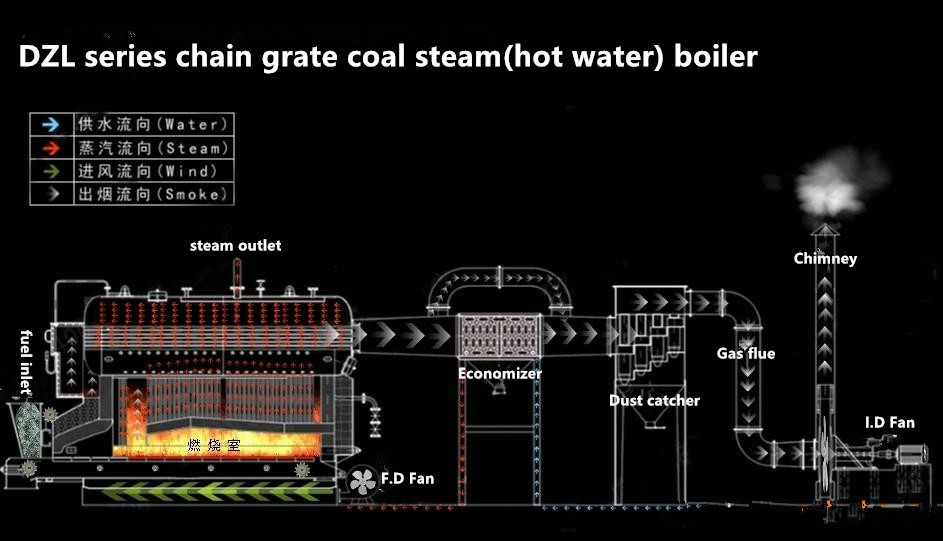

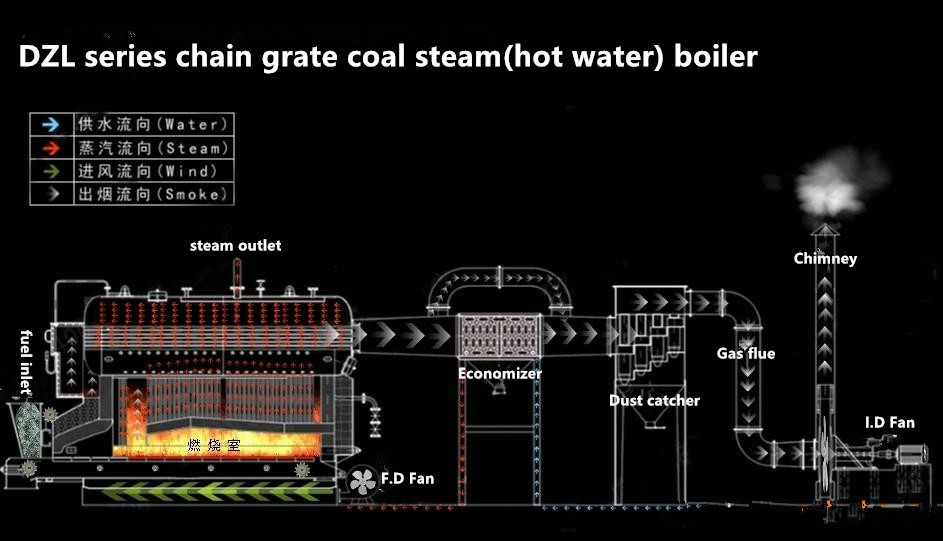

1ton 2ton 3 ton 4 ton 5 ton 6 ton 8 ton 10 ton coal steam boiler for garment industry Product descpription 3 ton Biomass steam boiler for garment industry which is a Horizontal type with a single drum belongs to the traveling grate boiler. It is a high efficient and environment-friendly product that can easily burn shaped biomass fuel or both pure and mixed coal with its economizer in the rear. Fuel: Biomass fuel forming; Bituminous coal; Bituminous coal and biomass blends  6000kg Biomass husk steam boiler generator electricity steam boiler for power application: Widely used in hospitals, universities, hotels, supermarkets, garment factories, canteens, paper mill, food processing factories, etc. 6000kg Biomass husk steam boiler generator electricity steam boiler for power structure: Furnace ,(gas solid separation equipment) separator ,solid material recycling equipment (feeder back), superheater, reheater ,economizer ,air preheater

6000kg Biomass husk steam boiler generator electricity steam boiler for power application: Widely used in hospitals, universities, hotels, supermarkets, garment factories, canteens, paper mill, food processing factories, etc. 6000kg Biomass husk steam boiler generator electricity steam boiler for power structure: Furnace ,(gas solid separation equipment) separator ,solid material recycling equipment (feeder back), superheater, reheater ,economizer ,air preheater  6000kg Biomass husk steam boiler generator electricity steam boiler for power Advantages: 1.With the novel furnace structure, the boiler can tackle the deformation of bulge caused by directly heating the bottom of the drum. 2. The boiler can avoid the crackles happening in the plates. 3. the drum adopt single pass threaded pipe, so it can not only strengthen the heat transfer effect but also has the function of self-cleaning gray at the same time 4.Novel arch design makes coal combustion and coal adaptability strong. 5. Grate side sealing structure avoids the shortcomings of uneven ventilation and burning out side sealing. 6 .Separate adjustable wind chamber under the fire grate is equipped and wind is fed from two sides. It adopts new type crack screw wind adjustment structure so that the wind adjustment and ventilation cross section proportion is 100%. Thus, it is easy to adjust and the wind is distributed symmetrically.

6000kg Biomass husk steam boiler generator electricity steam boiler for power Advantages: 1.With the novel furnace structure, the boiler can tackle the deformation of bulge caused by directly heating the bottom of the drum. 2. The boiler can avoid the crackles happening in the plates. 3. the drum adopt single pass threaded pipe, so it can not only strengthen the heat transfer effect but also has the function of self-cleaning gray at the same time 4.Novel arch design makes coal combustion and coal adaptability strong. 5. Grate side sealing structure avoids the shortcomings of uneven ventilation and burning out side sealing. 6 .Separate adjustable wind chamber under the fire grate is equipped and wind is fed from two sides. It adopts new type crack screw wind adjustment structure so that the wind adjustment and ventilation cross section proportion is 100%. Thus, it is easy to adjust and the wind is distributed symmetrically.  6000kg Biomass husk steam boiler generator electricity steam boiler for power Technical Parameters:

6000kg Biomass husk steam boiler generator electricity steam boiler for power Technical Parameters:

The fuels---biomass pellets:

Accessories

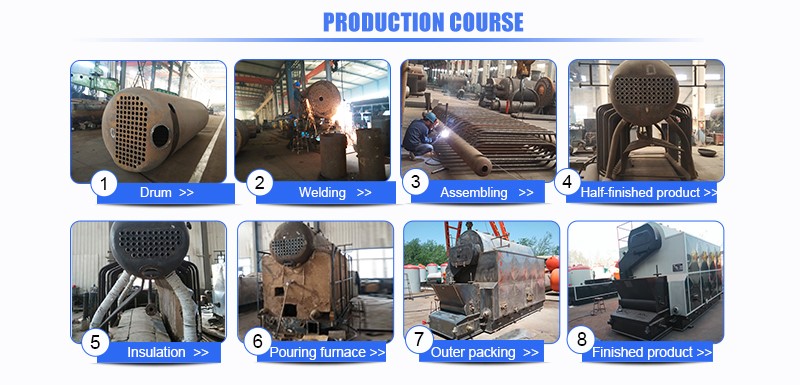

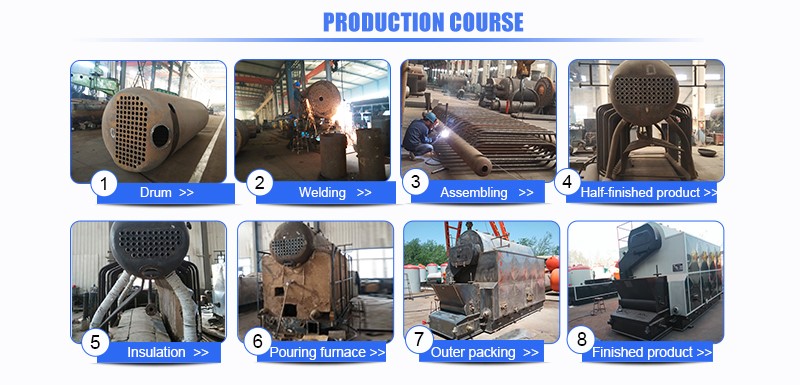

Accessories  production courses

production courses  Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Our Services Pre-sale service:

Our Services Pre-sale service:

1.According to the customer needs to recommend relative models machine.

2. According to the customer's special requirements to customize equipments.

3. Our engineers will supply the site and equipment drawing. After-sale service:

1. According to the purchase contract, our company can send engineers to help installation.

2. The quality guarantee is 1 year, not including the wearing parts.

3. Collecting customer feedback, solve the real problems faced by customers.

4. Our company supply spare parts all the year round. Besides, in the manufacturing process, clients are quite welcome to our factory to examine the actual quality and to carry out the follow-up inspection. customers Exhibition Customers: Factory Visiting Customers

Factory Visiting Customers  Certifications

Certifications  If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel: +86-13730106760 Email: linda at bangziboiler.com

If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel: +86-13730106760 Email: linda at bangziboiler.com

6000kg Biomass husk steam boiler generator electricity steam boiler for power application: Widely used in hospitals, universities, hotels, supermarkets, garment factories, canteens, paper mill, food processing factories, etc. 6000kg Biomass husk steam boiler generator electricity steam boiler for power structure: Furnace ,(gas solid separation equipment) separator ,solid material recycling equipment (feeder back), superheater, reheater ,economizer ,air preheater

6000kg Biomass husk steam boiler generator electricity steam boiler for power application: Widely used in hospitals, universities, hotels, supermarkets, garment factories, canteens, paper mill, food processing factories, etc. 6000kg Biomass husk steam boiler generator electricity steam boiler for power structure: Furnace ,(gas solid separation equipment) separator ,solid material recycling equipment (feeder back), superheater, reheater ,economizer ,air preheater  6000kg Biomass husk steam boiler generator electricity steam boiler for power Advantages: 1.With the novel furnace structure, the boiler can tackle the deformation of bulge caused by directly heating the bottom of the drum. 2. The boiler can avoid the crackles happening in the plates. 3. the drum adopt single pass threaded pipe, so it can not only strengthen the heat transfer effect but also has the function of self-cleaning gray at the same time 4.Novel arch design makes coal combustion and coal adaptability strong. 5. Grate side sealing structure avoids the shortcomings of uneven ventilation and burning out side sealing. 6 .Separate adjustable wind chamber under the fire grate is equipped and wind is fed from two sides. It adopts new type crack screw wind adjustment structure so that the wind adjustment and ventilation cross section proportion is 100%. Thus, it is easy to adjust and the wind is distributed symmetrically.

6000kg Biomass husk steam boiler generator electricity steam boiler for power Advantages: 1.With the novel furnace structure, the boiler can tackle the deformation of bulge caused by directly heating the bottom of the drum. 2. The boiler can avoid the crackles happening in the plates. 3. the drum adopt single pass threaded pipe, so it can not only strengthen the heat transfer effect but also has the function of self-cleaning gray at the same time 4.Novel arch design makes coal combustion and coal adaptability strong. 5. Grate side sealing structure avoids the shortcomings of uneven ventilation and burning out side sealing. 6 .Separate adjustable wind chamber under the fire grate is equipped and wind is fed from two sides. It adopts new type crack screw wind adjustment structure so that the wind adjustment and ventilation cross section proportion is 100%. Thus, it is easy to adjust and the wind is distributed symmetrically.  6000kg Biomass husk steam boiler generator electricity steam boiler for power Technical Parameters:

6000kg Biomass husk steam boiler generator electricity steam boiler for power Technical Parameters: | Project | Unit | Dzl1-0.7 | Dzl2-1.0 | Dzl-4-1.25 | Dzl6-1.25 | Dzl10-1.25 | Dzl15-1.25 |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 |

| rated steam pressure | MPa | 0.7 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| nominal steam temperature | ℃ | 170 | 183 | 194 | 194 | 194 | 194 |

| Rated inlet water temperature | ℃ | 20 | 20 | 20 | 20 | 20 | 60 |

| heating area | m² | 30.5 | 64.2 | 128 | 190.4 | 364.6 | 594.9 |

| Active grate area | m² | 2 | 3.6 | 5.29 | 7.37 | 12.67 | 16.11 |

| fuel | coal, biomass, pellets, biomass pellets, wood pellets, wood chips, sawdust, rice husk, solid fuel, dual fuel, multi fuel...etc | ||||||

| coal consumption | kg/h | 191.5 | 388 | 780 | 1155 | 1890 | 2250 |

| Exhaust gas temperature | ℃ | 158 | 167.5 | 165.5 | 166 | 156.7 | 153.5 |

| Design efficiency | % | 78.9 | 78.1 | 78 | 79 | 79.8 | 80.4 |

| Max transportation weight | t | 15 | 19.5 | 30.5 | 37.5 | 72 | 61 |

Accessories

Accessories  production courses

production courses  Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Our Services Pre-sale service:

Our Services Pre-sale service:1.According to the customer needs to recommend relative models machine.

2. According to the customer's special requirements to customize equipments.

3. Our engineers will supply the site and equipment drawing. After-sale service:

1. According to the purchase contract, our company can send engineers to help installation.

2. The quality guarantee is 1 year, not including the wearing parts.

3. Collecting customer feedback, solve the real problems faced by customers.

4. Our company supply spare parts all the year round. Besides, in the manufacturing process, clients are quite welcome to our factory to examine the actual quality and to carry out the follow-up inspection. customers Exhibition Customers:

Factory Visiting Customers

Factory Visiting Customers  Certifications

Certifications  If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel: +86-13730106760 Email: linda at bangziboiler.com

If any interest in our products, just please contact with me directly: Name: Linda Xu Skype: xuwenjuan86 Tel: +86-13730106760 Email: linda at bangziboiler.com You May Also Like

You May Also Like