Three Through Type and Horizontal Style Save Energy Boiler

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

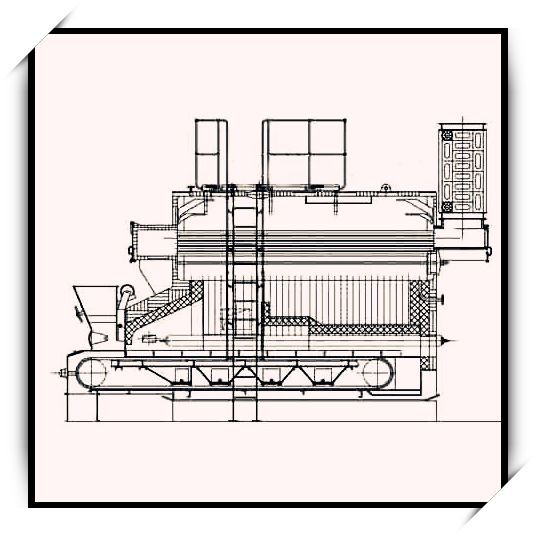

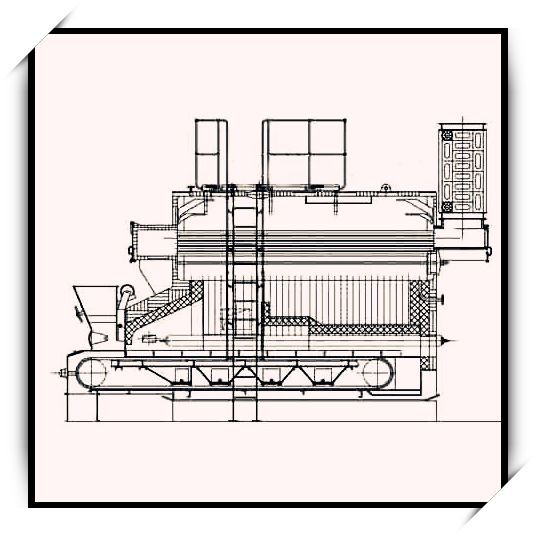

Three Through Type and Horizontal Style Save Energy Boiler DZL steam boiler General features of the DZL series steam boiler: Low pressure, horizontal, industrial, coal fired, fire tube, automatic chain grate steam boiler. The rated evaporation is 1 ton/hr , 2 ton/h, 4 ton/h, 6 ton/h, 10 ton/h, 15 ton/h, 20 ton/h.  Product advantage: 1. Spirally corrugated tube Function: (1) Heat transfer enhancement; (2) Improve the suppleness to avoid the tube plate cracking; (3) Clean groove itself. 2. Arched tube plate Function: (1) reduce the thermal stress of weld; (2) improve the tube plate suppleness; (3) simplify the structure and save the boiler room space. 3. Complete protection device Function: deal with the situation of overpressure, over-temperature, water shortage and flameout. 4. Up-tube layout Function: (1) Avoid the bulging on boiler drum; (2) Promote the water cycle (3)clean the sediment in the boiler bottom. 5. Airfoil flue Function: Lower the high temperature of tube plate flue gas. And then reduce the thermal load of the boiler bottom.

Product advantage: 1. Spirally corrugated tube Function: (1) Heat transfer enhancement; (2) Improve the suppleness to avoid the tube plate cracking; (3) Clean groove itself. 2. Arched tube plate Function: (1) reduce the thermal stress of weld; (2) improve the tube plate suppleness; (3) simplify the structure and save the boiler room space. 3. Complete protection device Function: deal with the situation of overpressure, over-temperature, water shortage and flameout. 4. Up-tube layout Function: (1) Avoid the bulging on boiler drum; (2) Promote the water cycle (3)clean the sediment in the boiler bottom. 5. Airfoil flue Function: Lower the high temperature of tube plate flue gas. And then reduce the thermal load of the boiler bottom.  Product feature 1. Low coal consumption and High thermal efficiency; 2. Reasonable water cycling, large water capacity and spacious steam volume; 3. Equipped with light chain belt assembly grate, blowing machine and draught fan. 4. High automation, mechanical adjustment of water supply, high and low water level alarm; 5. Low water and blowers interlocking protection; 6. Mechanical operation of boiler coaling, slag discharging; 7. Simple operation and quick installation. Technical parameters

Product feature 1. Low coal consumption and High thermal efficiency; 2. Reasonable water cycling, large water capacity and spacious steam volume; 3. Equipped with light chain belt assembly grate, blowing machine and draught fan. 4. High automation, mechanical adjustment of water supply, high and low water level alarm; 5. Low water and blowers interlocking protection; 6. Mechanical operation of boiler coaling, slag discharging; 7. Simple operation and quick installation. Technical parameters

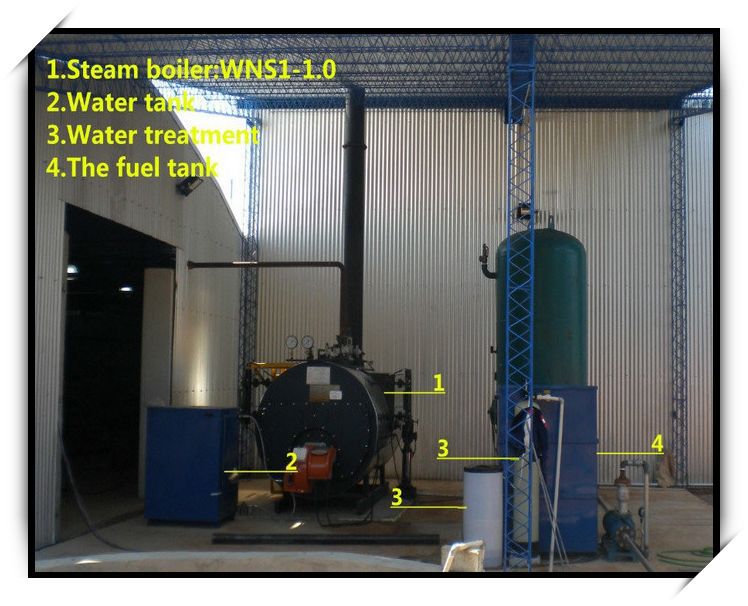

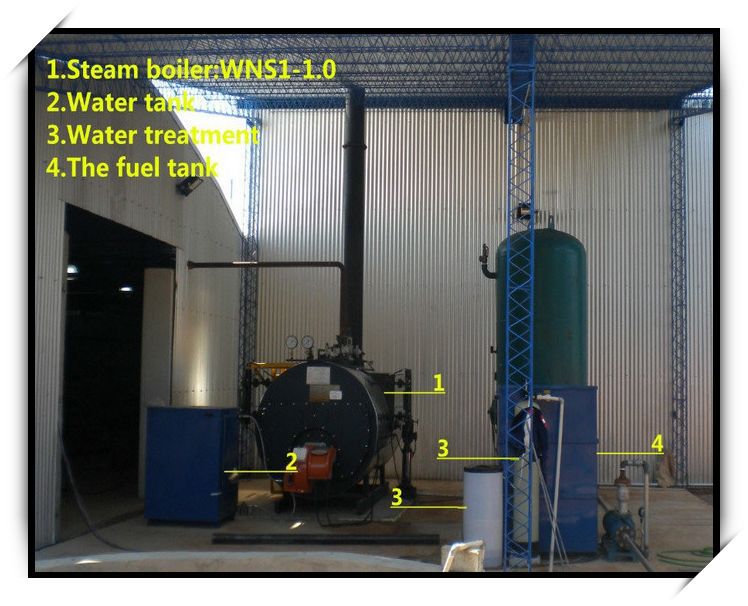

WNS steam boiler

WNS steam boiler  General features of WNS series steam boiler: 1. horizontal , gas & oil fired , water tube, industrial and low pressure; 2. wetback and three-backhaulstructure design; 3. With high efficiency economizer, the thermal efficiency can reach more than 90%. 4. The spring-loaded type explosion door ensures the boiler safety 5. The removable smoke boxfacilitates the maintenance 6. Internal micro positive pressure combustionreduces the low temperature corrosion. 7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.

General features of WNS series steam boiler: 1. horizontal , gas & oil fired , water tube, industrial and low pressure; 2. wetback and three-backhaulstructure design; 3. With high efficiency economizer, the thermal efficiency can reach more than 90%. 4. The spring-loaded type explosion door ensures the boiler safety 5. The removable smoke boxfacilitates the maintenance 6. Internal micro positive pressure combustionreduces the low temperature corrosion. 7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.  The product advantage: 1. Subulate furnace and corrugated furnace combination Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction 2. Smooth tube and spirally corrugated tube combination The smooth tube Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ; The spirally corrugated tube Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself. 3. The furnace sits in line with the combustion Function: (1) Make the structure more compact; (2) prolong its service life; Mark: The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving.

The product advantage: 1. Subulate furnace and corrugated furnace combination Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction 2. Smooth tube and spirally corrugated tube combination The smooth tube Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ; The spirally corrugated tube Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself. 3. The furnace sits in line with the combustion Function: (1) Make the structure more compact; (2) prolong its service life; Mark: The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving.

The measures of quality assurance as follow: 1. Strength calculation report with applied materials information; 2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; 3. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler; 4. Hydraulic test report: ensure the standard working pressure and safety;

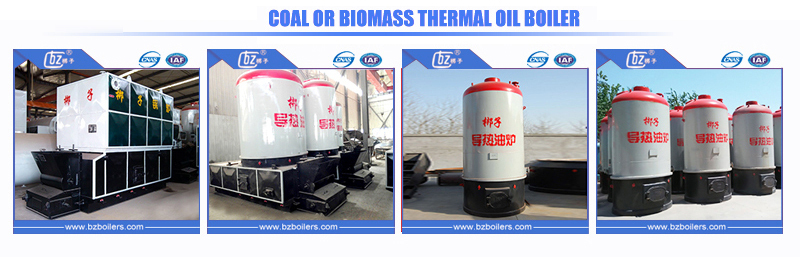

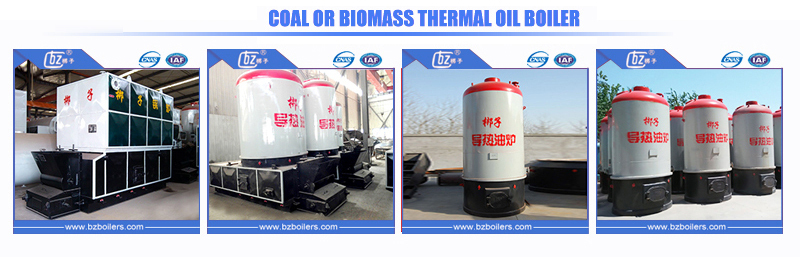

YGL biomass boiler Introduction of Coal Fired Thermal Oil Heater This boiler is custom’s first choose as for an equipment of low pressure with high temperature. It is fired with coal, oil or gas and used heat conduction oil as heat carrier. The boiler supplies the heating with a close cycle. It carries the hot oil to the heat-transfer equipment then back to the boiler through forced circulation of hot oil pump. It has a widespread use on various fields.  Key technologies: Heat Transfer Oil Boiler had obtained an international patented. 1. There are three to four layers of coil at the inner parts of the boiler with highly fume utilization rates.

Key technologies: Heat Transfer Oil Boiler had obtained an international patented. 1. There are three to four layers of coil at the inner parts of the boiler with highly fume utilization rates.

2. The thermal insulating layer is adopted by refractory cement pouring integrated with good isolation and high heating efficiency.

3. Outermost insulation is using the steel specialize in boiler with the good isolation. Characteristics about our products: 1. Rational construction with small size. It is easier to install the boiler with a low investment.

2. It can get a higher working temperature under normal pressure.

3. Heating transport with Liquid-phase. The pressure of saturated vapour is 70-80 times lower than water when the temperature is below 300. And the heat conduction oil seldom freezing in cold area.

4. It is a good substitution of water. It can be used in the places where is lack of water resource.

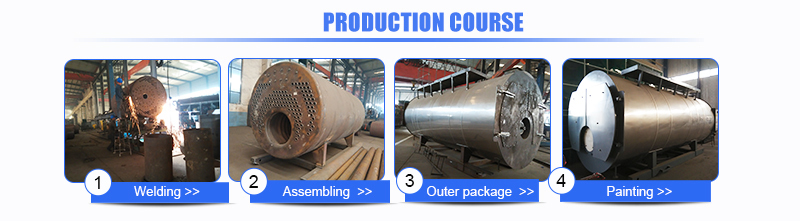

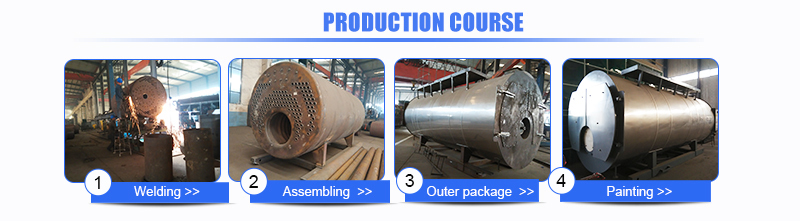

production courses 1 YLW

Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.

Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.  Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.

Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.  Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.

Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.  Contact Leeson Zhou Tel/Fax: +86 311 83893700 Cell/Whatsapp/Wechat: +86 13833185003 Website: www.bzboilers.com

Contact Leeson Zhou Tel/Fax: +86 311 83893700 Cell/Whatsapp/Wechat: +86 13833185003 Website: www.bzboilers.com

Product advantage: 1. Spirally corrugated tube Function: (1) Heat transfer enhancement; (2) Improve the suppleness to avoid the tube plate cracking; (3) Clean groove itself. 2. Arched tube plate Function: (1) reduce the thermal stress of weld; (2) improve the tube plate suppleness; (3) simplify the structure and save the boiler room space. 3. Complete protection device Function: deal with the situation of overpressure, over-temperature, water shortage and flameout. 4. Up-tube layout Function: (1) Avoid the bulging on boiler drum; (2) Promote the water cycle (3)clean the sediment in the boiler bottom. 5. Airfoil flue Function: Lower the high temperature of tube plate flue gas. And then reduce the thermal load of the boiler bottom.

Product advantage: 1. Spirally corrugated tube Function: (1) Heat transfer enhancement; (2) Improve the suppleness to avoid the tube plate cracking; (3) Clean groove itself. 2. Arched tube plate Function: (1) reduce the thermal stress of weld; (2) improve the tube plate suppleness; (3) simplify the structure and save the boiler room space. 3. Complete protection device Function: deal with the situation of overpressure, over-temperature, water shortage and flameout. 4. Up-tube layout Function: (1) Avoid the bulging on boiler drum; (2) Promote the water cycle (3)clean the sediment in the boiler bottom. 5. Airfoil flue Function: Lower the high temperature of tube plate flue gas. And then reduce the thermal load of the boiler bottom.  Product feature 1. Low coal consumption and High thermal efficiency; 2. Reasonable water cycling, large water capacity and spacious steam volume; 3. Equipped with light chain belt assembly grate, blowing machine and draught fan. 4. High automation, mechanical adjustment of water supply, high and low water level alarm; 5. Low water and blowers interlocking protection; 6. Mechanical operation of boiler coaling, slag discharging; 7. Simple operation and quick installation. Technical parameters

Product feature 1. Low coal consumption and High thermal efficiency; 2. Reasonable water cycling, large water capacity and spacious steam volume; 3. Equipped with light chain belt assembly grate, blowing machine and draught fan. 4. High automation, mechanical adjustment of water supply, high and low water level alarm; 5. Low water and blowers interlocking protection; 6. Mechanical operation of boiler coaling, slag discharging; 7. Simple operation and quick installation. Technical parameters | Project | Unit | Dzl1-0.7 | Dzl2-1.0 | Dzl-4-1.25 | Dzl6-1.25 | Dzl10-1.25 | Dzl15-1.25 |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 |

| rated steam pressure | MPa | 0.7 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| nominal steam temperature | ℃ | 170 | 183 | 194 | 194 | 194 | 194 |

| Rated inlet water temperature | ℃ | 20 | 20 | 20 | 20 | 20 | 60 |

| heating area | m² | 30.5 | 64.2 | 128 | 190.4 | 364.6 | 594.9 |

| Active grate area | m² | 2 | 3.6 | 5.29 | 7.37 | 12.67 | 16.11 |

| fuel | coal, biomass, pellets, biomass pellets, wood pellets, wood chips, sawdust, rice husk, solid fuel, dual fuel, multi fuel...etc | ||||||

| coal consumption | kg/h | 191.5 | 388 | 780 | 1155 | 1890 | 2250 |

| Exhaust gas temperature | ℃ | 158 | 167.5 | 165.5 | 166 | 156.7 | 153.5 |

| Design efficiency | % | 78.9 | 78.1 | 78 | 79 | 79.8 | 80.4 |

| Max transportation weight | t | 15 | 19.5 | 30.5 | 37.5 | 72 | 61 |

WNS steam boiler

WNS steam boiler  General features of WNS series steam boiler: 1. horizontal , gas & oil fired , water tube, industrial and low pressure; 2. wetback and three-backhaulstructure design; 3. With high efficiency economizer, the thermal efficiency can reach more than 90%. 4. The spring-loaded type explosion door ensures the boiler safety 5. The removable smoke boxfacilitates the maintenance 6. Internal micro positive pressure combustionreduces the low temperature corrosion. 7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.

General features of WNS series steam boiler: 1. horizontal , gas & oil fired , water tube, industrial and low pressure; 2. wetback and three-backhaulstructure design; 3. With high efficiency economizer, the thermal efficiency can reach more than 90%. 4. The spring-loaded type explosion door ensures the boiler safety 5. The removable smoke boxfacilitates the maintenance 6. Internal micro positive pressure combustionreduces the low temperature corrosion. 7. Equipped with protection devicesfor overheating, overpressure, lacking water, leak detection, flameout, etc. This ensures the boiler to operate safely and efficiently.  The product advantage: 1. Subulate furnace and corrugated furnace combination Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction 2. Smooth tube and spirally corrugated tube combination The smooth tube Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ; The spirally corrugated tube Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself. 3. The furnace sits in line with the combustion Function: (1) Make the structure more compact; (2) prolong its service life; Mark: The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving.

The product advantage: 1. Subulate furnace and corrugated furnace combination Function: (1) Make the structure more compact; (2) improve the thermal efficiency; (3) relieve the expansion and contraction 2. Smooth tube and spirally corrugated tube combination The smooth tube Function: Prevent the exhaust from condensing inside the boiler to prolong its service life ; The spirally corrugated tube Function: (1) relieve the expansion and contraction; (2) Heat transfer enhancement;; (3) clean groove by itself. 3. The furnace sits in line with the combustion Function: (1) Make the structure more compact; (2) prolong its service life; Mark: The combination of our gas fired boiler, imported burner and economizer are the perfect match, which is high-efficient, environment-friendly and energy-saving. The measures of quality assurance as follow: 1. Strength calculation report with applied materials information; 2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod; 3. 100% X-ray inspection report (welding seam): to ensure the quality of the entire boiler; 4. Hydraulic test report: ensure the standard working pressure and safety;

| Projects | unit | WNS1 | WNS2 | WNS4 | WNS6 | WNS10 | WNS15 | WNS20 | |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 | 20 | |

| Nominal steam pressure | Mpa | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Nominal steam temperature | °c | 194 | |||||||

| Rated inlet water temperature | °c | 20 | |||||||

| body heating surface | m² | 25.5 | 60 | 111 | 160 | 260 | 380 | 482 | |

| Economizer heating surface | m² | 5 | 10 | 16 | 25 | 30 | 46 | 62 | |

| Design thermal efficiency | % | 91.8 | |||||||

| Design environment temprature | °c | 20 | |||||||

| Design blowdown rate | % | 4 | |||||||

| Net weight of boiler | t | 6.5 | 9.8 | 14.8 | 20.7 | 30.4 | 43.3 | 50.4 | |

| operational water volume | t | 3 | 5 | 7.5 | 10.7 | 16.7 | 25 | 31.5 | |

| full water volume | t | 4 | 6.8 | 10 | 14.6 | 22.3 | 31.1 | 36.6 | |

| Fuel consumption | Natural gas | Nm3/h | 75.4 | 149 | 298 | 447 | 743.6 | 1084.4 | 1444.3 |

| Diesel | kg/h | 64 | 132 | 265 | 382 | 636 | 951 | 1267.6 | |

Key technologies: Heat Transfer Oil Boiler had obtained an international patented. 1. There are three to four layers of coil at the inner parts of the boiler with highly fume utilization rates.

Key technologies: Heat Transfer Oil Boiler had obtained an international patented. 1. There are three to four layers of coil at the inner parts of the boiler with highly fume utilization rates.2. The thermal insulating layer is adopted by refractory cement pouring integrated with good isolation and high heating efficiency.

3. Outermost insulation is using the steel specialize in boiler with the good isolation. Characteristics about our products: 1. Rational construction with small size. It is easier to install the boiler with a low investment.

2. It can get a higher working temperature under normal pressure.

3. Heating transport with Liquid-phase. The pressure of saturated vapour is 70-80 times lower than water when the temperature is below 300. And the heat conduction oil seldom freezing in cold area.

4. It is a good substitution of water. It can be used in the places where is lack of water resource.

| Projects | Unit | YGL-240S | YGL-350s | YGL-470s | YGL-700s | YGL-1000s | YGL-1400S |

| rated thermal power | kw | 240 | 350 | 470 | 700 | 1000 | 1400 |

| Max working pressure | Mpa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| max temperature of medium | °c | 300 | 300 | 300 | 300 | 300 | 300 |

| medium capacity of boiler | m3 | 0.14 | 0.2 | 0.3 | 0.6 | 0.8 | 1.05 |

| Pipe diameter | mm | 65 | 80 | 80 | 80 | 125 | 125 |

| thermal efficiency | % | 84.53 | 84.1 | 82.8 | 82.3 | 82.35 | 82.37 |

| Outer size | mm | Φ1350 *2655 | Φ1555 *2769 | Φ 1558 *3262 | Φ1758 *3660 | Φ1808 *4053 | Φ2250 *3942 |

| Circular flow of medium | m3/h | 18 | 30 | 40 | 60 | 60 | 80 |

| weight | kg | 2560 | 3480 | 3870 | 5340 | 7420 | 10000 |

production courses 1 YLW

Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.

Workshop We have totally five workshops which covers an area of nearly 3600 square meters and employ 600 person including more than 100 engineers and technicians. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received ISO9001 certification.  Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.

Customers Our products have been exported to many countries all over the world, including Russia, Southeast Asia, South America, North America, Africa, Mid-East, Romania, Mengolia, Vietnam, Indonesia, etc. The quality of products and our after-sale services have won us good reputation in the oversea market. So we warmly welcome cusotmers to pay a visit to our factory so that they will have a better idea about us and our products.  Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.

Certificates We have the ISO9001 certificate and the National Grade-A boiler certificate, also with the Green product certificate and many Patent for invention certificates, etc.  Contact Leeson Zhou Tel/Fax: +86 311 83893700 Cell/Whatsapp/Wechat: +86 13833185003 Website: www.bzboilers.com

Contact Leeson Zhou Tel/Fax: +86 311 83893700 Cell/Whatsapp/Wechat: +86 13833185003 Website: www.bzboilers.com You May Also Like

You May Also Like