Coal fired steam boiler

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

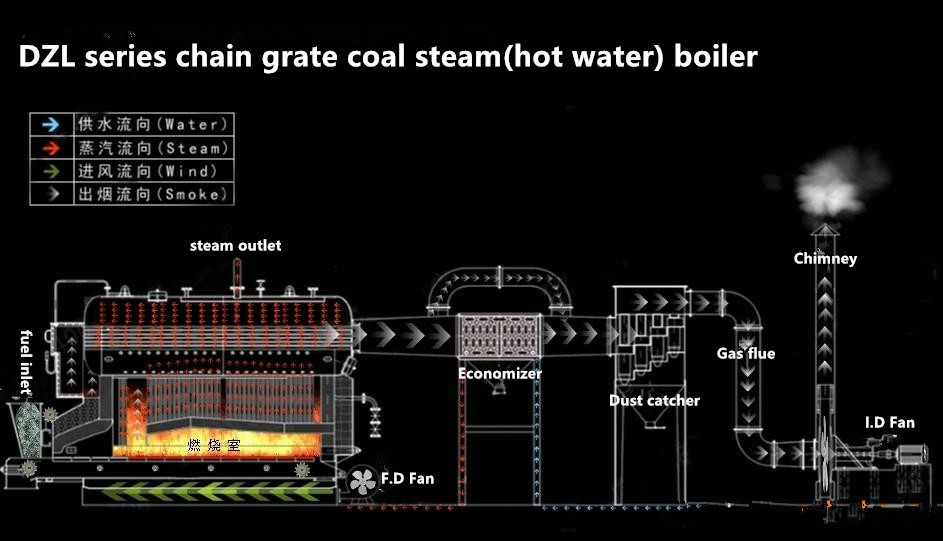

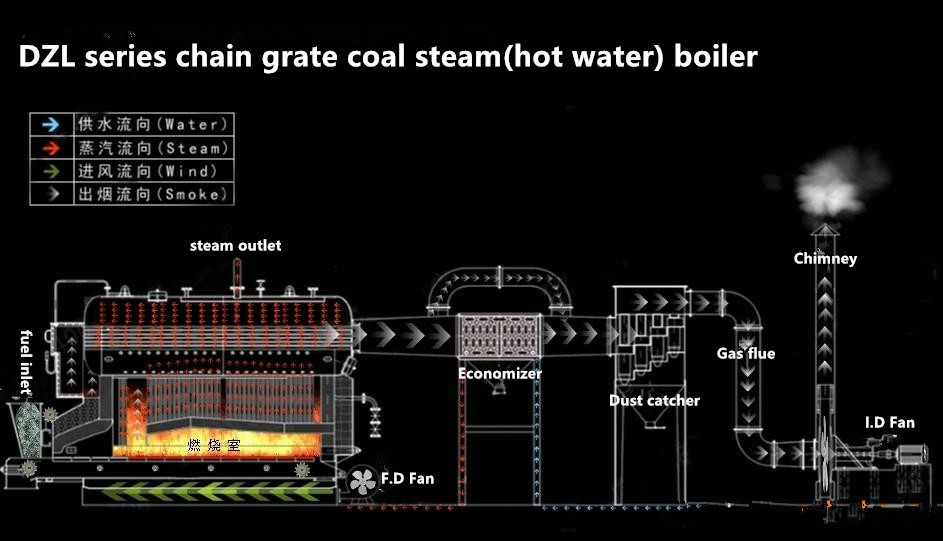

Coal fired steam boiler Product descpription Main feature of coal steam boiler Boiler Capacity: 1-20t/h. Rated working pressure: 1.25-1.6Mpa or higher pressure. Can be adjusted according to customer’s demand. Fuel: Coal & Wood. Thermal Efficiency: ≥90%. Power Supply: Three phase 380V±10%, 50Hz±2%. Saturated steam temperature:194-204°c.  Performance Feature of the coal boiler 1. The structure DZL/DZH boiler horizontal fast-assembling fire tube boilers and natural circulation. 2. Advanced design: The main heating tube of the boiler uses 20# low and medium pressure boiler seamless pipe and the boiler drum uses the special steel. 3. The front arch of the boiler use refractory brick. The back arch is low and long, so it has good combustion. Both blank flue and side wall use refractory bricks. Front wall and back wall of the boiler use common refractory bricks. 4. Reasonable air distribution in the grate, large combustion chamber, widely types of coal. The DZL boiler could use bituminous, anthracite or mixed coal. Because of high temperature flue gas enters the settling chamber firstly, and then from both sides of the flue into the wings, front smoke box, so it has good dust abatement.

Performance Feature of the coal boiler 1. The structure DZL/DZH boiler horizontal fast-assembling fire tube boilers and natural circulation. 2. Advanced design: The main heating tube of the boiler uses 20# low and medium pressure boiler seamless pipe and the boiler drum uses the special steel. 3. The front arch of the boiler use refractory brick. The back arch is low and long, so it has good combustion. Both blank flue and side wall use refractory bricks. Front wall and back wall of the boiler use common refractory bricks. 4. Reasonable air distribution in the grate, large combustion chamber, widely types of coal. The DZL boiler could use bituminous, anthracite or mixed coal. Because of high temperature flue gas enters the settling chamber firstly, and then from both sides of the flue into the wings, front smoke box, so it has good dust abatement.

Technical parameters of industrial coal fired steam boiler

Technical parameters of industrial coal fired steam boiler

Application The steam boiler can be used for producing desired hot water for product manufacturing process in the weave factory, printing and dying, papermaking, and rubber, plastic chemical, pharmaceutical, etc. And for heating room, bath, air conditional, and daily life water in the factories, departments, hotels, schools, restaurants, services industries etc.  Accessories All auxiliaries

Accessories All auxiliaries

production courses

production courses  Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Company Introduction 1, Spirit: Supply Reliable & High Efficient Heating System. 2, Produce Capacity: More Than 1000 Sets Of Boilers (5000 T/H) Can Be Produced By us Per Year. Class A Boiler Manufacturer. Class A1, D2 Pressure Vessel Manufacturer. 3, Certification:All products have passed ISO9001:2008 & ASME International Quality Management System Certification, also can provide CE, AS, GOST certification. 4, Business Promise:Each Boiler System Parts Is From First Class Brand All Over The World or China. 5, Quality Strict monitor. From The Material, Welding, To Finished Boiler Shipment; From Project Establishment, Drawing Design, To Final Audit. Advanced automatic welding with 100% passed penetrate X-Ray inspection. 6, User: We Are The Stable And Long Term Supplier Of Many Top 500 Groups All Over The World. Such As PetroChina, Sinopec, Nestle, Mercedes-Benz, Coca Cola, Etc,. We are looking for long terms cooperation boilerusers,distributors, importers, agents worldwide! Certifications

Company Introduction 1, Spirit: Supply Reliable & High Efficient Heating System. 2, Produce Capacity: More Than 1000 Sets Of Boilers (5000 T/H) Can Be Produced By us Per Year. Class A Boiler Manufacturer. Class A1, D2 Pressure Vessel Manufacturer. 3, Certification:All products have passed ISO9001:2008 & ASME International Quality Management System Certification, also can provide CE, AS, GOST certification. 4, Business Promise:Each Boiler System Parts Is From First Class Brand All Over The World or China. 5, Quality Strict monitor. From The Material, Welding, To Finished Boiler Shipment; From Project Establishment, Drawing Design, To Final Audit. Advanced automatic welding with 100% passed penetrate X-Ray inspection. 6, User: We Are The Stable And Long Term Supplier Of Many Top 500 Groups All Over The World. Such As PetroChina, Sinopec, Nestle, Mercedes-Benz, Coca Cola, Etc,. We are looking for long terms cooperation boilerusers,distributors, importers, agents worldwide! Certifications  customers Exhibition Customers:

customers Exhibition Customers:  Factory Visiting Customers

Factory Visiting Customers  FAQ Q1: How to install a boiler? A1: Bangzi Boiler provides completed installation drawing and manual, or send engineer abroad for installation guidance Q2:How many years is the boiler’s life span A2: The boiler is designed for 10years life span, but under good maintenance, usually the boiler can use at least 16years, Bangzi Boiler provide full life after-sales service to each sold boiler Q3: How to choose a boiler model? A3: Confirm the type (steam or hot water), capacity, working pressure (or output temperature) and fuel(coal, biomass, gas or oil or other fuel) of the boiler, BangziBoiler will suggest a suitable model based on your usage. Q4: How is the warranty term? A4: If any problems caused for quality during the warranty period, the Seller will repair or replace the broken parts for free, if the problem caused from the client’s side, the Seller will help supply the spare part at lowest cost. Contact us

FAQ Q1: How to install a boiler? A1: Bangzi Boiler provides completed installation drawing and manual, or send engineer abroad for installation guidance Q2:How many years is the boiler’s life span A2: The boiler is designed for 10years life span, but under good maintenance, usually the boiler can use at least 16years, Bangzi Boiler provide full life after-sales service to each sold boiler Q3: How to choose a boiler model? A3: Confirm the type (steam or hot water), capacity, working pressure (or output temperature) and fuel(coal, biomass, gas or oil or other fuel) of the boiler, BangziBoiler will suggest a suitable model based on your usage. Q4: How is the warranty term? A4: If any problems caused for quality during the warranty period, the Seller will repair or replace the broken parts for free, if the problem caused from the client’s side, the Seller will help supply the spare part at lowest cost. Contact us

Performance Feature of the coal boiler 1. The structure DZL/DZH boiler horizontal fast-assembling fire tube boilers and natural circulation. 2. Advanced design: The main heating tube of the boiler uses 20# low and medium pressure boiler seamless pipe and the boiler drum uses the special steel. 3. The front arch of the boiler use refractory brick. The back arch is low and long, so it has good combustion. Both blank flue and side wall use refractory bricks. Front wall and back wall of the boiler use common refractory bricks. 4. Reasonable air distribution in the grate, large combustion chamber, widely types of coal. The DZL boiler could use bituminous, anthracite or mixed coal. Because of high temperature flue gas enters the settling chamber firstly, and then from both sides of the flue into the wings, front smoke box, so it has good dust abatement.

Performance Feature of the coal boiler 1. The structure DZL/DZH boiler horizontal fast-assembling fire tube boilers and natural circulation. 2. Advanced design: The main heating tube of the boiler uses 20# low and medium pressure boiler seamless pipe and the boiler drum uses the special steel. 3. The front arch of the boiler use refractory brick. The back arch is low and long, so it has good combustion. Both blank flue and side wall use refractory bricks. Front wall and back wall of the boiler use common refractory bricks. 4. Reasonable air distribution in the grate, large combustion chamber, widely types of coal. The DZL boiler could use bituminous, anthracite or mixed coal. Because of high temperature flue gas enters the settling chamber firstly, and then from both sides of the flue into the wings, front smoke box, so it has good dust abatement. | Project | Unit | Dzl1-0.7 | Dzl2-1.0 | Dzl-4-1.25 | Dzl6-1.25 | Dzl10-1.25 | Dzl15-1.25 |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 |

| rated steam pressure | MPa | 0.7 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| nominal steam temperature | ℃ | 170 | 183 | 194 | 194 | 194 | 194 |

| Rated inlet water temperature | ℃ | 20 | 20 | 20 | 20 | 20 | 60 |

| heating area | m² | 30.5 | 64.2 | 128 | 190.4 | 364.6 | 594.9 |

| Active grate area | m² | 2 | 3.6 | 5.29 | 7.37 | 12.67 | 16.11 |

| fuel | coal, biomass, pellets, biomass pellets, wood pellets, wood chips, sawdust, rice husk, solid fuel, dual fuel, multi fuel...etc | ||||||

| coal consumption | kg/h | 191.5 | 388 | 780 | 1155 | 1890 | 2250 |

| Exhaust gas temperature | ℃ | 158 | 167.5 | 165.5 | 166 | 156.7 | 153.5 |

| Design efficiency | % | 78.9 | 78.1 | 78 | 79 | 79.8 | 80.4 |

| Max transportation weight | t | 15 | 19.5 | 30.5 | 37.5 | 72 | 61 |

Accessories All auxiliaries

Accessories All auxiliaries NO. | Auxiliary | Quantity |

1 | Water treatment | 1 Piece |

2 | Blowing fan | 1 Piece |

3 | Induced draft fan | 1 Piece |

4 | Electrical control cabinet | 1 Piece |

5 | Steam distributor | 1 Piece |

6 | Chimney | 1 Piece |

7 | Smoke flow | 1 Piece |

8 | Dust catcher | 1 Piece |

9 | Water feeding pump | 2 Piece |

10 | Fuel feeding machine | 1 Piece |

11 | Speed governor | 1 Piece |

12 | Fuel economizer | 1 Piece |

13 | Slag mover | 1 Piece |

14 | Water level control gage | 1 Piece |

15 | Valves & instrument | 1 Batch |

16 | Spare parts | Several |

production courses

production courses  Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Company Information Hebei Gold Bangzi Boiler Co., Ltd, as a large-scale 30 years professional manufacturing enterprise for A level boiler and D2 level pressure vessel, is a 30 years factory with ISO certification . The factory specializes in the design, development , production and marketing of boilers and pressure vessels. Our products cover coal fired, biomass fired, gas and oil fired hot water boiler, steam boiler, thermal oil boiler, waste heat boiler and devulcanizer...etc.

Company Introduction 1, Spirit: Supply Reliable & High Efficient Heating System. 2, Produce Capacity: More Than 1000 Sets Of Boilers (5000 T/H) Can Be Produced By us Per Year. Class A Boiler Manufacturer. Class A1, D2 Pressure Vessel Manufacturer. 3, Certification:All products have passed ISO9001:2008 & ASME International Quality Management System Certification, also can provide CE, AS, GOST certification. 4, Business Promise:Each Boiler System Parts Is From First Class Brand All Over The World or China. 5, Quality Strict monitor. From The Material, Welding, To Finished Boiler Shipment; From Project Establishment, Drawing Design, To Final Audit. Advanced automatic welding with 100% passed penetrate X-Ray inspection. 6, User: We Are The Stable And Long Term Supplier Of Many Top 500 Groups All Over The World. Such As PetroChina, Sinopec, Nestle, Mercedes-Benz, Coca Cola, Etc,. We are looking for long terms cooperation boilerusers,distributors, importers, agents worldwide! Certifications

Company Introduction 1, Spirit: Supply Reliable & High Efficient Heating System. 2, Produce Capacity: More Than 1000 Sets Of Boilers (5000 T/H) Can Be Produced By us Per Year. Class A Boiler Manufacturer. Class A1, D2 Pressure Vessel Manufacturer. 3, Certification:All products have passed ISO9001:2008 & ASME International Quality Management System Certification, also can provide CE, AS, GOST certification. 4, Business Promise:Each Boiler System Parts Is From First Class Brand All Over The World or China. 5, Quality Strict monitor. From The Material, Welding, To Finished Boiler Shipment; From Project Establishment, Drawing Design, To Final Audit. Advanced automatic welding with 100% passed penetrate X-Ray inspection. 6, User: We Are The Stable And Long Term Supplier Of Many Top 500 Groups All Over The World. Such As PetroChina, Sinopec, Nestle, Mercedes-Benz, Coca Cola, Etc,. We are looking for long terms cooperation boilerusers,distributors, importers, agents worldwide! Certifications  customers Exhibition Customers:

customers Exhibition Customers:  Factory Visiting Customers

Factory Visiting Customers  FAQ Q1: How to install a boiler? A1: Bangzi Boiler provides completed installation drawing and manual, or send engineer abroad for installation guidance Q2:How many years is the boiler’s life span A2: The boiler is designed for 10years life span, but under good maintenance, usually the boiler can use at least 16years, Bangzi Boiler provide full life after-sales service to each sold boiler Q3: How to choose a boiler model? A3: Confirm the type (steam or hot water), capacity, working pressure (or output temperature) and fuel(coal, biomass, gas or oil or other fuel) of the boiler, BangziBoiler will suggest a suitable model based on your usage. Q4: How is the warranty term? A4: If any problems caused for quality during the warranty period, the Seller will repair or replace the broken parts for free, if the problem caused from the client’s side, the Seller will help supply the spare part at lowest cost. Contact us

FAQ Q1: How to install a boiler? A1: Bangzi Boiler provides completed installation drawing and manual, or send engineer abroad for installation guidance Q2:How many years is the boiler’s life span A2: The boiler is designed for 10years life span, but under good maintenance, usually the boiler can use at least 16years, Bangzi Boiler provide full life after-sales service to each sold boiler Q3: How to choose a boiler model? A3: Confirm the type (steam or hot water), capacity, working pressure (or output temperature) and fuel(coal, biomass, gas or oil or other fuel) of the boiler, BangziBoiler will suggest a suitable model based on your usage. Q4: How is the warranty term? A4: If any problems caused for quality during the warranty period, the Seller will repair or replace the broken parts for free, if the problem caused from the client’s side, the Seller will help supply the spare part at lowest cost. Contact us

You May Also Like

You May Also Like