DZL single drum coal-fired water tube steam boiler for textile processing

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

DZL single drum coal-fired water tube steam boiler for textile processing Product descpription

1. Adopting automatic screw feeding, with reasonable second air technology and half gasification structure helping fuel combusting completely, the thermal efficiency can reach more than 90%. Stable flame, producing hot water cautiously. 2. Environmental biomass fuels are widely promoted by the state because it’s cheaper price and wide sources. Operating cost is One-sixth of electric boiler, one-third of oil boiler. 3. Control system: Installing microcomputer to operate with one-button, people just set the process, and it can work automatically during the operating time. Once any abnormal situation to happen, stopping automatically with sound-light alarm, and pointing to the failure code, so it saves time to maintain. 4. Our protected device is safe and reliable. Selecting superior pressure controller, safety valve, low water alarm, overpressure alarm, over-temperature alarm, in order to make boilers operate safely. 5. Reasonable over-all structure to cover little space, hearing no sound. It is easy to install, because there is no need to set up tall chimney, with a very low failure rate. 6. It is simple to clean slag only after burning completing. Technical parameters of coal biomass chicken proces meat steam boiler manufacturer in china

Pictures of coal biomass chicken proces meat steam boiler manufacturer in china

Company Information

Company Information

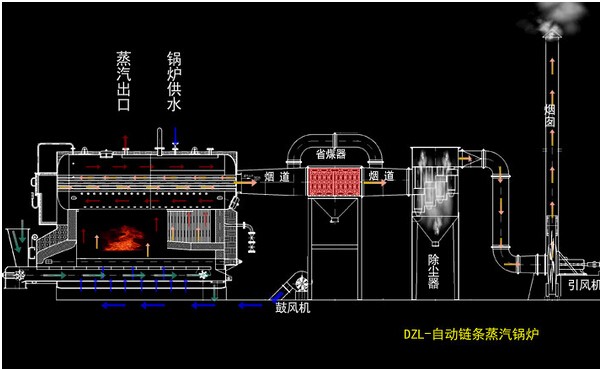

BOILER FLOW CHART

BOILER FLOW CHART  FAQ Warranty and after-sale service Sitong promises the top quality of every set of machine and best after-sales service as follings : (1) the boiler body guarantee is two years , for accessories three years (2) during the guarantee period , if the main body defective without any worker’s wrong operation , Sitong should replaces the parts for free or prepare the good for free. (3) Sitong should provide boiler techinial service and operation guaidance life long. (4) Regarding to the installation and training , the buyer bears all the correlative charges (accommodation and food , round -trip tickets) (5) The buyer need to pay 80USD to our engineer per day.

FAQ Warranty and after-sale service Sitong promises the top quality of every set of machine and best after-sales service as follings : (1) the boiler body guarantee is two years , for accessories three years (2) during the guarantee period , if the main body defective without any worker’s wrong operation , Sitong should replaces the parts for free or prepare the good for free. (3) Sitong should provide boiler techinial service and operation guaidance life long. (4) Regarding to the installation and training , the buyer bears all the correlative charges (accommodation and food , round -trip tickets) (5) The buyer need to pay 80USD to our engineer per day.

1. Adopting automatic screw feeding, with reasonable second air technology and half gasification structure helping fuel combusting completely, the thermal efficiency can reach more than 90%. Stable flame, producing hot water cautiously. 2. Environmental biomass fuels are widely promoted by the state because it’s cheaper price and wide sources. Operating cost is One-sixth of electric boiler, one-third of oil boiler. 3. Control system: Installing microcomputer to operate with one-button, people just set the process, and it can work automatically during the operating time. Once any abnormal situation to happen, stopping automatically with sound-light alarm, and pointing to the failure code, so it saves time to maintain. 4. Our protected device is safe and reliable. Selecting superior pressure controller, safety valve, low water alarm, overpressure alarm, over-temperature alarm, in order to make boilers operate safely. 5. Reasonable over-all structure to cover little space, hearing no sound. It is easy to install, because there is no need to set up tall chimney, with a very low failure rate. 6. It is simple to clean slag only after burning completing. Technical parameters of coal biomass chicken proces meat steam boiler manufacturer in china

| Project | Unit | Dzl1-0.7 | Dzl2-1.0 | Dzl-4-1.25 | Dzl6-1.25 | Dzl10-1.25 | Dzl15-1.25 |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 |

| rated steam pressure | MPa | 0.7 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| nominal steam temperature | ℃ | 170 | 183 | 194 | 194 | 194 | 194 |

| Rated inlet water temperature | ℃ | 20 | 20 | 20 | 20 | 20 | 60 |

| heating area | m² | 30.5 | 64.2 | 128 | 190.4 | 364.6 | 594.9 |

| Active grate area | m² | 2 | 3.6 | 5.29 | 7.37 | 12.67 | 16.11 |

| fuel | coal, biomass, pellets, biomass pellets, wood pellets, wood chips, sawdust, rice husk, solid fuel, dual fuel, multi fuel...etc | ||||||

| coal consumption | kg/h | 191.5 | 388 | 780 | 1155 | 1890 | 2250 |

| Exhaust gas temperature | ℃ | 158 | 167.5 | 165.5 | 166 | 156.7 | 153.5 |

| Design efficiency | % | 78.9 | 78.1 | 78 | 79 | 79.8 | 80.4 |

| Max transportation weight | t | 15 | 19.5 | 30.5 | 37.5 | 72 | 61 |

Pictures of coal biomass chicken proces meat steam boiler manufacturer in china

Company Information

Company Information

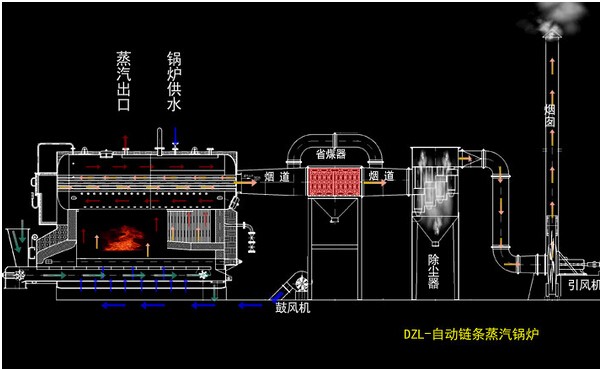

BOILER FLOW CHART

BOILER FLOW CHART  FAQ Warranty and after-sale service Sitong promises the top quality of every set of machine and best after-sales service as follings : (1) the boiler body guarantee is two years , for accessories three years (2) during the guarantee period , if the main body defective without any worker’s wrong operation , Sitong should replaces the parts for free or prepare the good for free. (3) Sitong should provide boiler techinial service and operation guaidance life long. (4) Regarding to the installation and training , the buyer bears all the correlative charges (accommodation and food , round -trip tickets) (5) The buyer need to pay 80USD to our engineer per day.

FAQ Warranty and after-sale service Sitong promises the top quality of every set of machine and best after-sales service as follings : (1) the boiler body guarantee is two years , for accessories three years (2) during the guarantee period , if the main body defective without any worker’s wrong operation , Sitong should replaces the parts for free or prepare the good for free. (3) Sitong should provide boiler techinial service and operation guaidance life long. (4) Regarding to the installation and training , the buyer bears all the correlative charges (accommodation and food , round -trip tickets) (5) The buyer need to pay 80USD to our engineer per day.

Related Keywords

Related Keywords

You May Also Like

You May Also Like