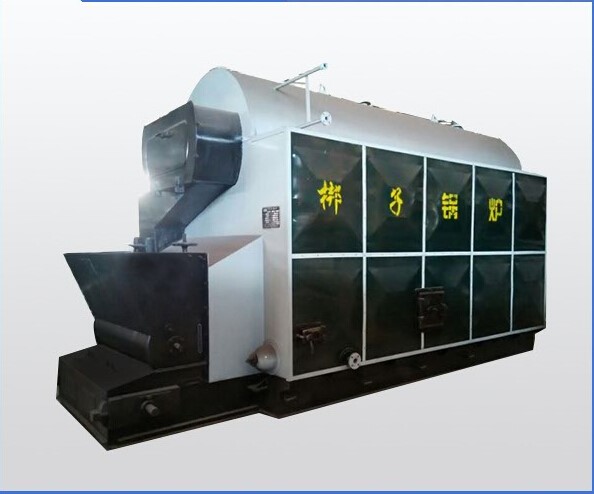

Shijiazhuang coal fired steam boiler with steam turbine

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

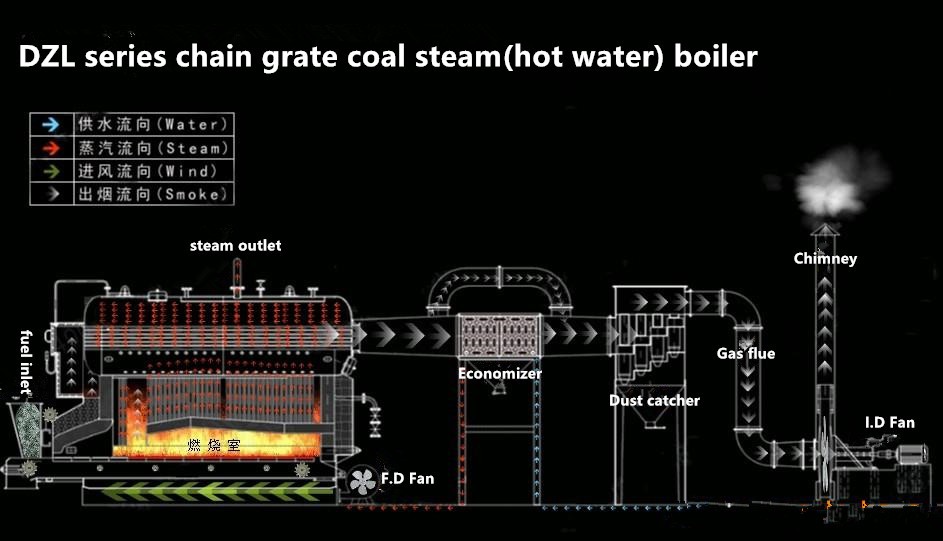

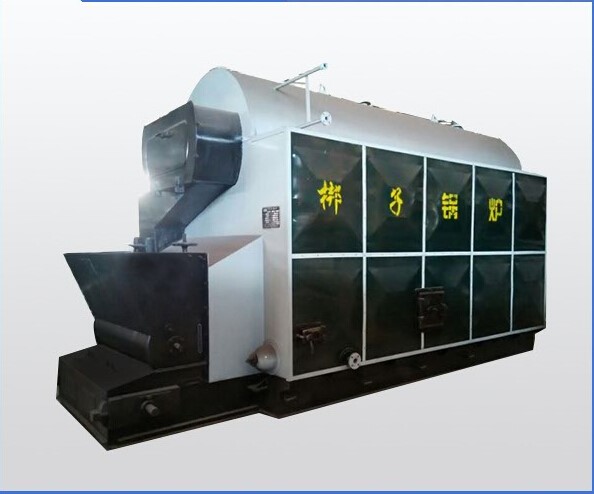

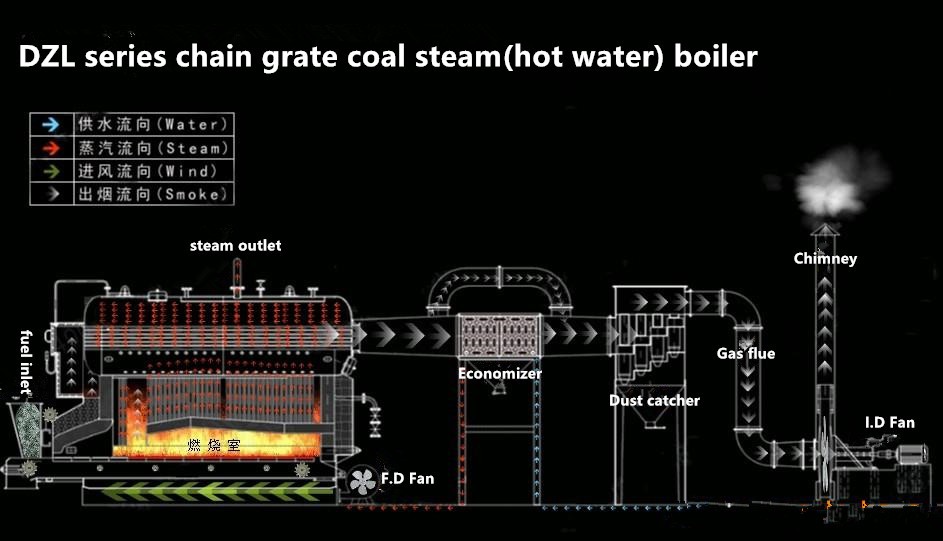

Shijiazhuang coal fired steam boiler with steam turbine Dear Customer: We have a Trade Assurance Amount US $100,000 granted by Alibaba.com. It means you will receive 100% refund of the Trade Assurance Amount for orders not meeting agreed delivery or quality terms. Product descpription This boiler adopt chain grate,suitable for molding pellet fuel,can add a small amount of wood,wood block,also can burn with coal. This boiler adopt the newest achievements in scientific research, such as:Arched Tube plate, thread smoke tube etc, solve the tube plate crack of shell type boiler, Water wall tube burst, low efficiency, insufficient of power,Poor pf coal type adaptability etc.  Combustion Processe: The fuel burning at the furnace through, the exhaust gas flow from the boiler barrel bottom to the smoke window outlet on the Eight character wall, then enter convection bank at the both wings, next enter the thread smoke tube through the front smoke box, pass by economizer, dust remover, and induced draft fan, finally discharged to the atmosphere by chimney.

Combustion Processe: The fuel burning at the furnace through, the exhaust gas flow from the boiler barrel bottom to the smoke window outlet on the Eight character wall, then enter convection bank at the both wings, next enter the thread smoke tube through the front smoke box, pass by economizer, dust remover, and induced draft fan, finally discharged to the atmosphere by chimney.

Feeding System Introduction: 1.Conveyor feeding mode (For biomass particles) 2.Elevating automatic feeding (For coal) 3.Blast feeding (For size of less than 50mm of small sawdust, or rice husk) 4.Screw feeder Advantages: 1.No need special protection when power off. 2.Higher efficiency,heating fast. 3.Safe and reliable. 4.Easy to install. Technical Parameters:

Feeding System Introduction: 1.Conveyor feeding mode (For biomass particles) 2.Elevating automatic feeding (For coal) 3.Blast feeding (For size of less than 50mm of small sawdust, or rice husk) 4.Screw feeder Advantages: 1.No need special protection when power off. 2.Higher efficiency,heating fast. 3.Safe and reliable. 4.Easy to install. Technical Parameters:

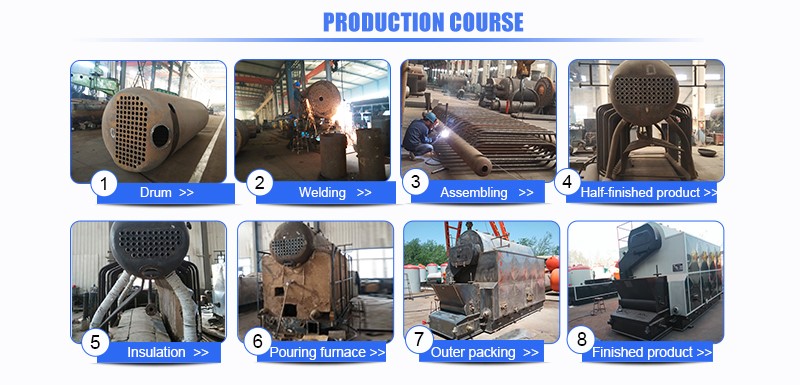

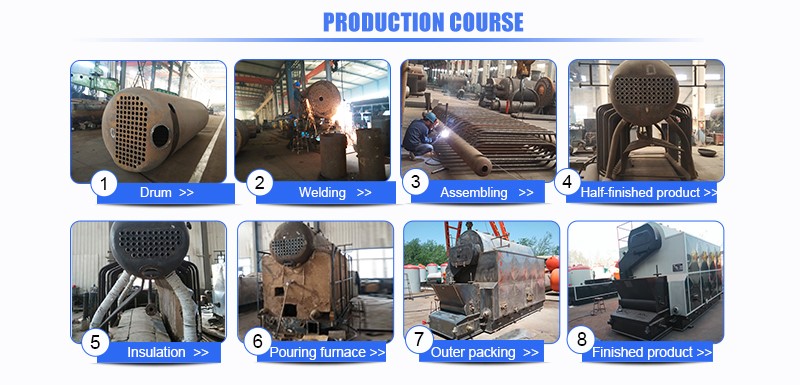

production courses  Accessories:

Accessories:  Why Choose us? 1.Chinese Famous Brand 2.Super High Quality, Competitive Price 3.Big Production Ability 4.Fast Delivery, Excellent After-sale Service 5.Certificate ISO9001, CE, A level certificate Packaging & Shipping

Why Choose us? 1.Chinese Famous Brand 2.Super High Quality, Competitive Price 3.Big Production Ability 4.Fast Delivery, Excellent After-sale Service 5.Certificate ISO9001, CE, A level certificate Packaging & Shipping  Company Information Hebei Gold Bangzi Boiler Co., Ltd, is devoted to heat energy field and has the word’s leading heating technology which are specialized in manufacture all kinds of boilers which included Hot Water Boiler , Steam Boiler, Thermal oil boiler, waste heat boiler , pressure container,etc . Our product have won the trust and support from our customers both at home and abroad ,which have been exported to Southeast Asia, Central Europe, Middle East and other countries .welcome your inquiry .

Company Information Hebei Gold Bangzi Boiler Co., Ltd, is devoted to heat energy field and has the word’s leading heating technology which are specialized in manufacture all kinds of boilers which included Hot Water Boiler , Steam Boiler, Thermal oil boiler, waste heat boiler , pressure container,etc . Our product have won the trust and support from our customers both at home and abroad ,which have been exported to Southeast Asia, Central Europe, Middle East and other countries .welcome your inquiry .  One-stop service

One-stop service

You only need to provide what you need, and the rest,We will provide product design,manufacturing, transportation, installation team installed faction, guide the operation and so on. We guarantee to provide you with satisfactory service. customers Exhibition Customers: Factory Visiting Customers

Factory Visiting Customers  Certifications

Certifications  Our Services Warranty and after-sale service Sitong promises the top quality of every set of machine and best after-sales service as followings : (A) The boiler body guarantee is two years , for accessories three years (B) During the guarantee period , if the main body defective or broken without wrong operating , Sitong must replace the parts for free or prepare the spare-parts for free. (C) Sitong should provide boiler technical service and operation guidance for whole life long. (D) Regarding to the installation and training , the buyer should take all the correlative charges (accommodation and food , round -trip tickets) Contact us

Our Services Warranty and after-sale service Sitong promises the top quality of every set of machine and best after-sales service as followings : (A) The boiler body guarantee is two years , for accessories three years (B) During the guarantee period , if the main body defective or broken without wrong operating , Sitong must replace the parts for free or prepare the spare-parts for free. (C) Sitong should provide boiler technical service and operation guidance for whole life long. (D) Regarding to the installation and training , the buyer should take all the correlative charges (accommodation and food , round -trip tickets) Contact us

Combustion Processe: The fuel burning at the furnace through, the exhaust gas flow from the boiler barrel bottom to the smoke window outlet on the Eight character wall, then enter convection bank at the both wings, next enter the thread smoke tube through the front smoke box, pass by economizer, dust remover, and induced draft fan, finally discharged to the atmosphere by chimney.

Combustion Processe: The fuel burning at the furnace through, the exhaust gas flow from the boiler barrel bottom to the smoke window outlet on the Eight character wall, then enter convection bank at the both wings, next enter the thread smoke tube through the front smoke box, pass by economizer, dust remover, and induced draft fan, finally discharged to the atmosphere by chimney.

Feeding System Introduction: 1.Conveyor feeding mode (For biomass particles) 2.Elevating automatic feeding (For coal) 3.Blast feeding (For size of less than 50mm of small sawdust, or rice husk) 4.Screw feeder Advantages: 1.No need special protection when power off. 2.Higher efficiency,heating fast. 3.Safe and reliable. 4.Easy to install. Technical Parameters:

Feeding System Introduction: 1.Conveyor feeding mode (For biomass particles) 2.Elevating automatic feeding (For coal) 3.Blast feeding (For size of less than 50mm of small sawdust, or rice husk) 4.Screw feeder Advantages: 1.No need special protection when power off. 2.Higher efficiency,heating fast. 3.Safe and reliable. 4.Easy to install. Technical Parameters: | Project | Unit | Dzl1-0.7 | Dzl2-1.0 | Dzl-4-1.25 | Dzl6-1.25 | Dzl10-1.25 | Dzl15-1.25 |

| rated evaporation | t/h | 1 | 2 | 4 | 6 | 10 | 15 |

| rated steam pressure | MPa | 0.7 | 1.0 | 1.25 | 1.25 | 1.25 | 1.25 |

| nominal steam temperature | ℃ | 170 | 183 | 194 | 194 | 194 | 194 |

| Rated inlet water temperature | ℃ | 20 | 20 | 20 | 20 | 20 | 60 |

| heating area | m² | 30.5 | 64.2 | 128 | 190.4 | 364.6 | 594.9 |

| Active grate area | m² | 2 | 3.6 | 5.29 | 7.37 | 12.67 | 16.11 |

| fuel | coal, biomass, pellets, biomass pellets, wood pellets, wood chips, sawdust, rice husk, solid fuel, dual fuel, multi fuel...etc | ||||||

| coal consumption | kg/h | 191.5 | 388 | 780 | 1155 | 1890 | 2250 |

| Exhaust gas temperature | ℃ | 158 | 167.5 | 165.5 | 166 | 156.7 | 153.5 |

| Design efficiency | % | 78.9 | 78.1 | 78 | 79 | 79.8 | 80.4 |

| Max transportation weight | t | 15 | 19.5 | 30.5 | 37.5 | 72 | 61 |

Accessories:

Accessories:  Why Choose us? 1.Chinese Famous Brand 2.Super High Quality, Competitive Price 3.Big Production Ability 4.Fast Delivery, Excellent After-sale Service 5.Certificate ISO9001, CE, A level certificate Packaging & Shipping

Why Choose us? 1.Chinese Famous Brand 2.Super High Quality, Competitive Price 3.Big Production Ability 4.Fast Delivery, Excellent After-sale Service 5.Certificate ISO9001, CE, A level certificate Packaging & Shipping  Company Information Hebei Gold Bangzi Boiler Co., Ltd, is devoted to heat energy field and has the word’s leading heating technology which are specialized in manufacture all kinds of boilers which included Hot Water Boiler , Steam Boiler, Thermal oil boiler, waste heat boiler , pressure container,etc . Our product have won the trust and support from our customers both at home and abroad ,which have been exported to Southeast Asia, Central Europe, Middle East and other countries .welcome your inquiry .

Company Information Hebei Gold Bangzi Boiler Co., Ltd, is devoted to heat energy field and has the word’s leading heating technology which are specialized in manufacture all kinds of boilers which included Hot Water Boiler , Steam Boiler, Thermal oil boiler, waste heat boiler , pressure container,etc . Our product have won the trust and support from our customers both at home and abroad ,which have been exported to Southeast Asia, Central Europe, Middle East and other countries .welcome your inquiry .  One-stop service

One-stop serviceYou only need to provide what you need, and the rest,We will provide product design,manufacturing, transportation, installation team installed faction, guide the operation and so on. We guarantee to provide you with satisfactory service. customers Exhibition Customers:

Factory Visiting Customers

Factory Visiting Customers  Certifications

Certifications  Our Services Warranty and after-sale service Sitong promises the top quality of every set of machine and best after-sales service as followings : (A) The boiler body guarantee is two years , for accessories three years (B) During the guarantee period , if the main body defective or broken without wrong operating , Sitong must replace the parts for free or prepare the spare-parts for free. (C) Sitong should provide boiler technical service and operation guidance for whole life long. (D) Regarding to the installation and training , the buyer should take all the correlative charges (accommodation and food , round -trip tickets) Contact us

Our Services Warranty and after-sale service Sitong promises the top quality of every set of machine and best after-sales service as followings : (A) The boiler body guarantee is two years , for accessories three years (B) During the guarantee period , if the main body defective or broken without wrong operating , Sitong must replace the parts for free or prepare the spare-parts for free. (C) Sitong should provide boiler technical service and operation guidance for whole life long. (D) Regarding to the installation and training , the buyer should take all the correlative charges (accommodation and food , round -trip tickets) Contact us

Related Keywords

Related Keywords

You May Also Like

You May Also Like