Heat media thermal oil heater for chipboard and timber drying

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

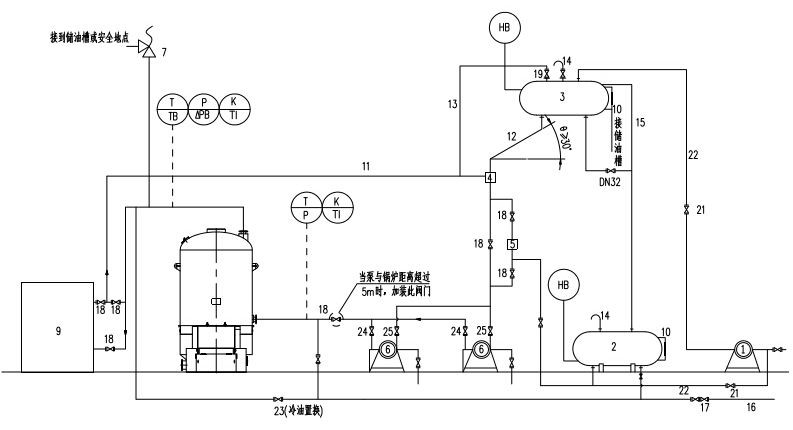

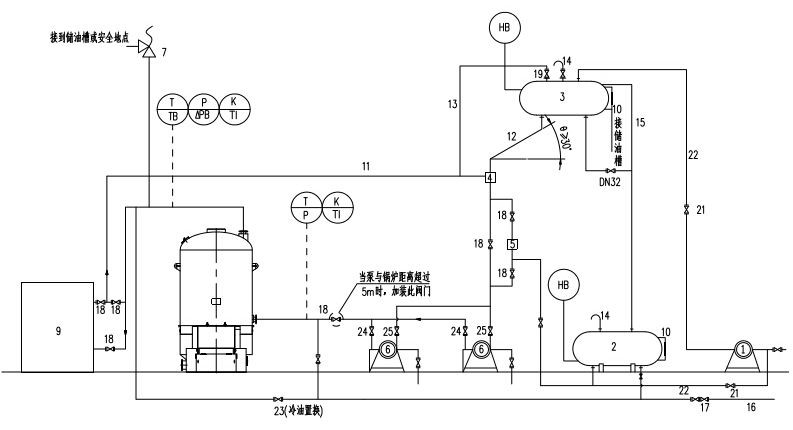

Heat media thermal oil heater for chipboard and timber drying YLL YYL(W) series industrial oil&gas fired thermal oil heater: Product features: 1.Reasonable structure and small volumn which is easy to install

2.Achieve high temperature in low pressure 3.Oil and gas fired ,high efficiency and environmental

4.Supply heat closed and in cycling with high heat efficiency.

5.Carry the heat with liquid,and the 70-80times lower pressure than saturated steam within 300°C

6.The heat conduction oil is not easy to freeze in cold areas

7.Better to replace the steam boiler where is lack of water source

8.It is extensively used in different industrial fields.

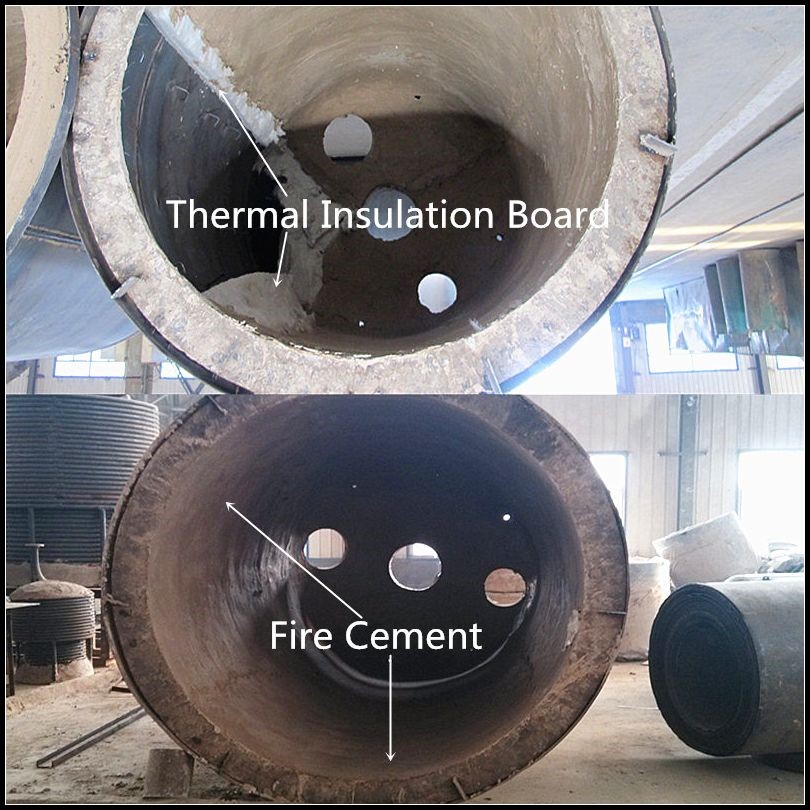

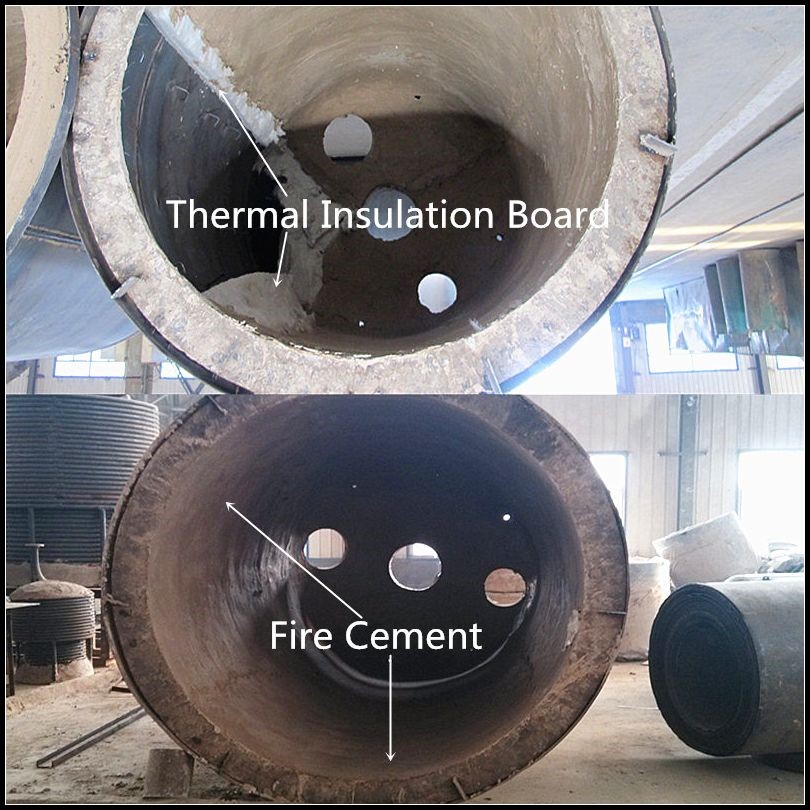

9. Unique coil design and innovation in structure of our company

10.Fast temperature rise and fuel saving ,makes it occupy the market quickly.

700KW-3500KW Biomass & coal thermal oil heater technical parameter

700KW-3500KW Biomass & coal thermal oil heater technical parameter

Coal or biomass fired thermal oil heater auxilaries

Packaging & Shipping

Packaging & Shipping  Workshop Show

Workshop Show

Customer Visit

Customer Visit  Certifications

Certifications  Contact

Contact

2.Achieve high temperature in low pressure 3.Oil and gas fired ,high efficiency and environmental

4.Supply heat closed and in cycling with high heat efficiency.

5.Carry the heat with liquid,and the 70-80times lower pressure than saturated steam within 300°C

6.The heat conduction oil is not easy to freeze in cold areas

7.Better to replace the steam boiler where is lack of water source

8.It is extensively used in different industrial fields.

9. Unique coil design and innovation in structure of our company

10.Fast temperature rise and fuel saving ,makes it occupy the market quickly.

700KW-3500KW Biomass & coal thermal oil heater technical parameter

700KW-3500KW Biomass & coal thermal oil heater technical parameter | Projects | Units | YLL-700 | YLL-1000 | YLL-1200 | YLL-1400 | YLL-2000 | YLL-2400 | YLL-2900 | YLL-3500 |

| rated thermal power | kw | 700 | 1000 | 1200 | 1400 | 2000 | 2400 | 2900 | 3500 |

| rated working pressure | MPa | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| highest working temperature | ℃ | 320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| Oil volumn in the boiler | m³ | 0.55 | 0.7 | 0.9 | 1.1 | 1.45 | 1.6 | 2.2 | 2.5 |

| Cycle oil volume | m³/h | 60 | 60 | 80 | 80 | 160 | 160 | 180 | 200 |

| pipe diameter | DN | 100 | 125 | 125 | 125 | 150 | 150 | 150 | 200 |

| coal consumption | kgk/h | 145 | 178 | 220 | 265 | 390 | 465 | 560 | 650 |

| thermal efficiency | % | more than 76% | more than 78% | ||||||

| fuel | coal, biomass, pellets, wood chips, wood pellets, biomass pellets, sawdust, solid fuel, dual fuel...etc | ||||||||

| transportation weight | t | 14.5 | 15.3 | 16.8 | 17.5 | 20 | 24.5 | 37.76 | |

Packaging & Shipping

Packaging & Shipping  Workshop Show

Workshop Show

Customer Visit

Customer Visit  Certifications

Certifications  Contact

Contact

You May Also Like

You May Also Like