Most popular vertical automatic stoker coal and biomass thermic fluid boiler

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

YLL Most popular vertical automatic stoker coal and biomass thermic fluid boiler YLL series 700KW-3500KW biomass pellet fired thermic fluid boiler

YLL series 700KW-3500KW biomass pellet fired thermic fluid boiler

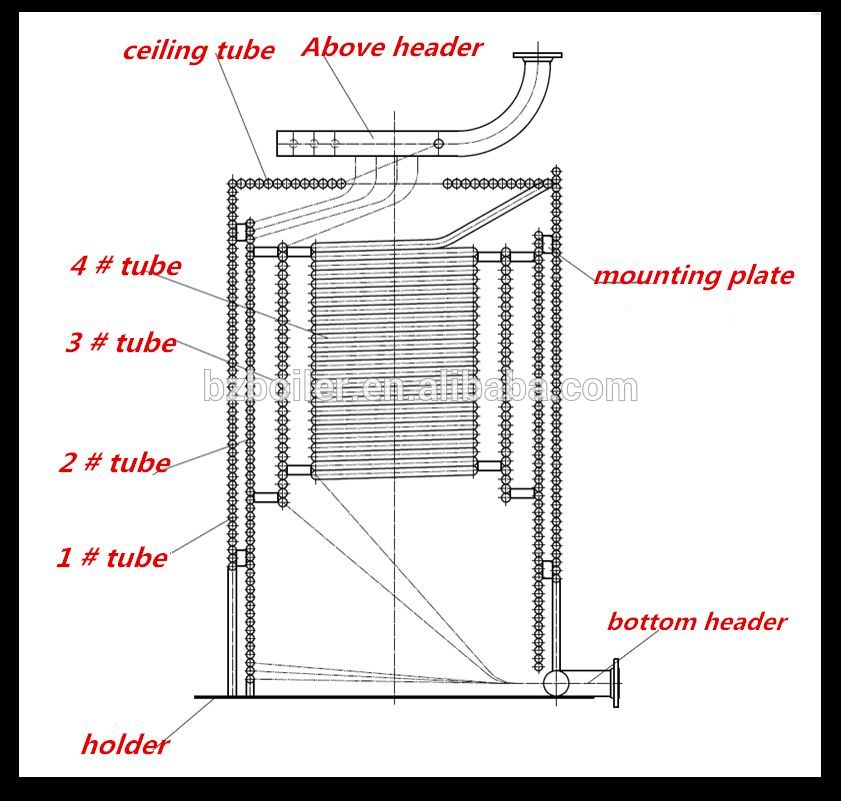

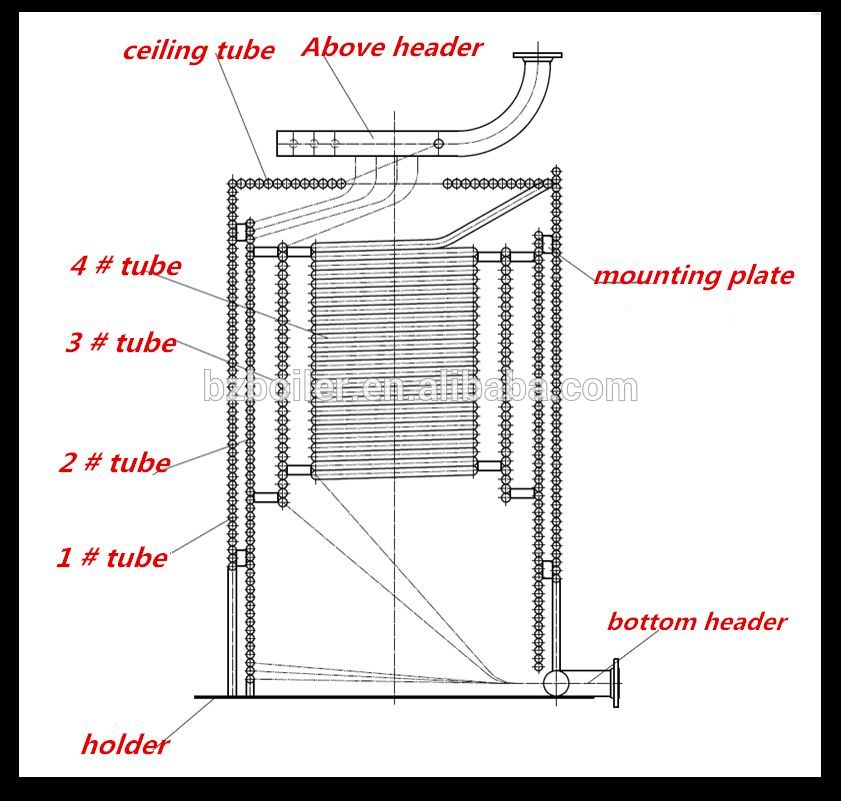

1.Designed with horizontal, three passes, all-wet back structure. 2.Fire tubes are surrounded by thermal oil, and these design making efficient up to 76%. 3.Threaded tube: Strengthen the heat transfer, increase the oil steam boiler heat efficiency 4.Big combustion room design: increase furnace heating area, decrease thermal oil boiler size, and reduce the emission of the Nox Corrugated hearth make the oil steam boiler safer. Application of 700KW-3500KW biomass pellet thermic fluid boiler

Widely used in chemical industry, plastics industry, coatings and automotive industries, bitumen industry, construction equipment industry, shipbuilding industry, apparel clothing, washing, ironing, the pharmaceutical industry, biotechnology, food industry, sauna and beauty, hotels, restaurants, sports, fitness and other places where need energy.

Features of YLL 700KW-3500KW biomass pellets thermic fluid boiler

·Horizontal three-pass central symmetry low level layout

·Full wet-back structure

·Corrugated furnace

·Full docking welded structure

·Front and rear smoke box double seal structure

·Furnace exit installation of blast doors

·Automatic intelligent control

YLL series 700KW-3500KW biomass pellets thermic fluid boiler

controlling and safety systems 1. The controlling and safety systems are interlocked in an electric control cabinet (ECC). 2. The burning and security operation are controlled by ECC. It has the following basic functions :

Protection program of automatic ignition

Locking and protection program of operation

Protection program of extinction

Protection program of completion

Protection program of water pumps (pressure loss)

Protection program of ignition failure

Protection program of combustion engine malfunction

Protection program of combustion engine flameout

Protection program of gas leakage

3. Alarm system

Sound-light alarm of steam pressure and super-high steam pressure

Sound-light alarm of high and low limit water level

Sound-light alarm of pressure loss in water pumps YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler

working principle YLL series 700KW-3500KW Coal/Biomass thermic fluid boiler

YLL series 700KW-3500KW Coal/Biomass thermic fluid boiler

technical parameter Note: for this company is continuously developing technological parameters can be changed without notice,technical parameters shall prevail to drawings. YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler pictures

Note: for this company is continuously developing technological parameters can be changed without notice,technical parameters shall prevail to drawings. YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler pictures

YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler auxiliayy machinery :

YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler auxiliayy machinery :

Workshop Show

Workshop Show  Customer Visit

Customer Visit  Contact

Contact

YLL series 700KW-3500KW biomass pellet fired thermic fluid boiler

YLL series 700KW-3500KW biomass pellet fired thermic fluid boiler 1.Designed with horizontal, three passes, all-wet back structure. 2.Fire tubes are surrounded by thermal oil, and these design making efficient up to 76%. 3.Threaded tube: Strengthen the heat transfer, increase the oil steam boiler heat efficiency 4.Big combustion room design: increase furnace heating area, decrease thermal oil boiler size, and reduce the emission of the Nox Corrugated hearth make the oil steam boiler safer. Application of 700KW-3500KW biomass pellet thermic fluid boiler

Widely used in chemical industry, plastics industry, coatings and automotive industries, bitumen industry, construction equipment industry, shipbuilding industry, apparel clothing, washing, ironing, the pharmaceutical industry, biotechnology, food industry, sauna and beauty, hotels, restaurants, sports, fitness and other places where need energy.

Features of YLL 700KW-3500KW biomass pellets thermic fluid boiler

·Horizontal three-pass central symmetry low level layout

·Full wet-back structure

·Corrugated furnace

·Full docking welded structure

·Front and rear smoke box double seal structure

·Furnace exit installation of blast doors

·Automatic intelligent control

YLL series 700KW-3500KW biomass pellets thermic fluid boiler

controlling and safety systems 1. The controlling and safety systems are interlocked in an electric control cabinet (ECC). 2. The burning and security operation are controlled by ECC. It has the following basic functions :

Protection program of automatic ignition

Locking and protection program of operation

Protection program of extinction

Protection program of completion

Protection program of water pumps (pressure loss)

Protection program of ignition failure

Protection program of combustion engine malfunction

Protection program of combustion engine flameout

Protection program of gas leakage

3. Alarm system

Sound-light alarm of steam pressure and super-high steam pressure

Sound-light alarm of high and low limit water level

Sound-light alarm of pressure loss in water pumps YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler

working principle

YLL series 700KW-3500KW Coal/Biomass thermic fluid boiler

YLL series 700KW-3500KW Coal/Biomass thermic fluid boiler technical parameter

Note: for this company is continuously developing technological parameters can be changed without notice,technical parameters shall prevail to drawings. YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler pictures

Note: for this company is continuously developing technological parameters can be changed without notice,technical parameters shall prevail to drawings. YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler pictures

YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler auxiliayy machinery :

YLL series 700KW-3500KW Coal/Biomass fired thermic fluid boiler auxiliayy machinery :

Workshop Show

Workshop Show  Customer Visit

Customer Visit  Contact

Contact

You May Also Like

You May Also Like