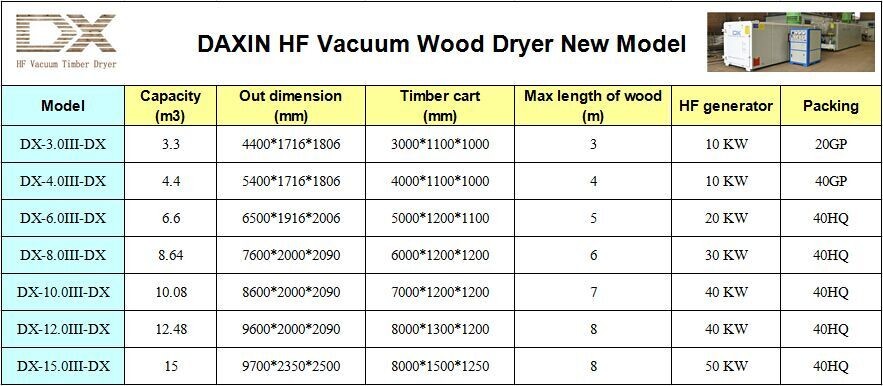

Vacuum Dryer High Frequency Wood Dryer

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

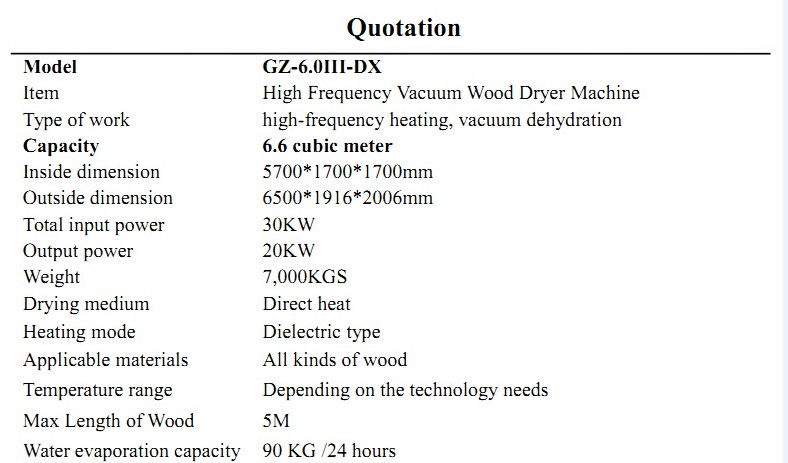

Product Description Vacuum Dryer High Frequency Wood Dryer

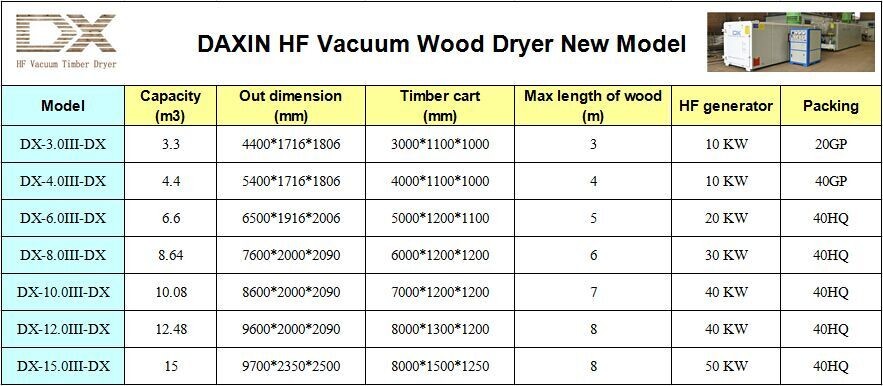

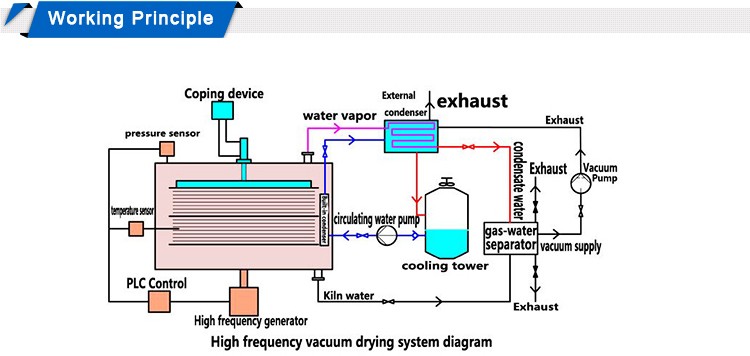

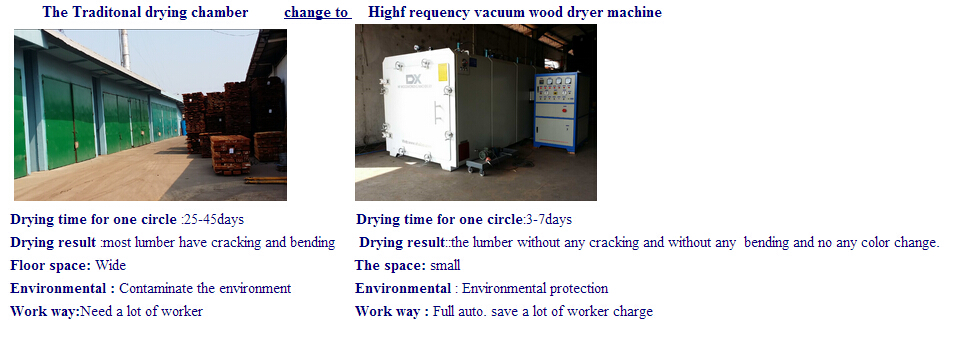

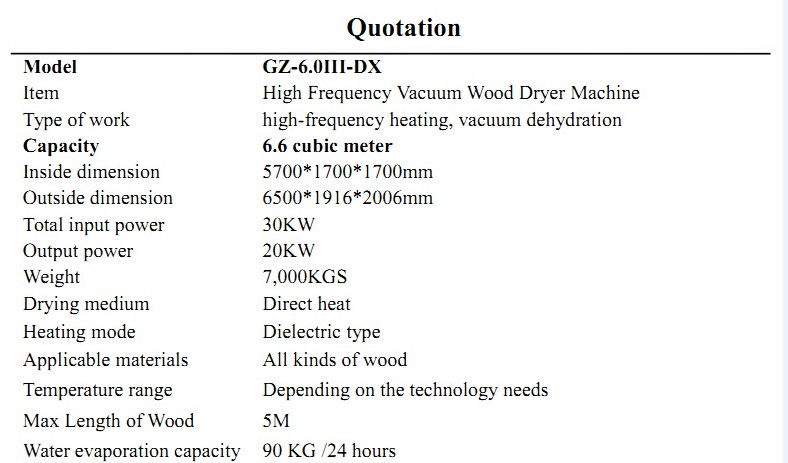

High frequency vacuum wood drying kiln is a new generation wood drying equipment.

This machine is the result of design combining high frequency medium heating technology and vacuum cryogenic dehydration technology, greatly reduced drying time.

1. To dry all kinds of wood in board or column type, slab type, cant type, timber type etc..

2. To dry all kinds of wood in veneer type.

3. To dry all kinds of wood in bending type.

Mary Email: haibo1 @vhaibo.com

Mob:+86-13663110303

Skype: vhaibo

Tel: +86-311-89836929; Fax: +86-311-86682328

Web:www.hfwoodworking.com

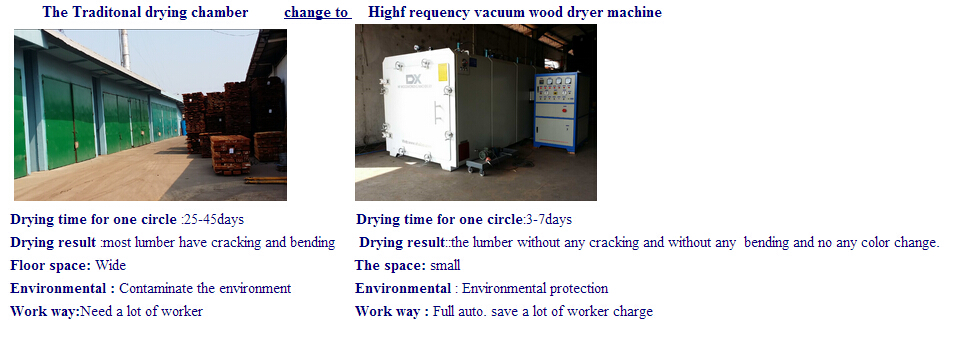

Features of High frequency vacuum wood dryer: Vacuum Drying — 60℃ starting to vaporize , which can reduce wood cracking and deformation while achieving low temperature drying

Features of High frequency vacuum wood dryer: Vacuum Drying — 60℃ starting to vaporize , which can reduce wood cracking and deformation while achieving low temperature drying

Warp Deformation Recovering --- Wood clamped by hydraulic system before drying, warping deformation to be recovered when soften , making outturn greatly improving and make easy palletizing

Quick Heating --- No need heat conduction, inside and outside of wood timber are heated at the same time

Fast Dehydration--- During the heating process, stepped temperature difference between inside and outside of wood can speed up the water movement from inside wood to outside wood

High Quality--- Avoid outside & inside cracking and color change, by taking control of heating speed, relative vacuum degree and condensing rate.

Good Adaptability---It can achieve both low temperature and high temperature drying, also can eliminate stress , solidify resin and apply to dry almost all kinds of wood

Full-automatic & Easy operation --- Automatic feeding and discharging device , drying proceeding under unattended mode

Cost Saving--- Low dry shrinkage and material saving

Sterilization function & Eco-friendly

Advantages of High frequency vacuum wood dryer

1)Heating fast and uniformly, fast drying(:more than10 times faster than conventional steam dryer);

2)Saving labor, cost and drying time;

3)Full-automatic, easy to control and operate; flexible and simple;

4)High outturn percentage, no crack, no deformation;

5)Environmental protection;

6)New square design tank increase the availability of the inner space;

7)Bacteria and worm killing, high outturn percentage ;

8)Drying apply for all kinds of wood

Detailed Images

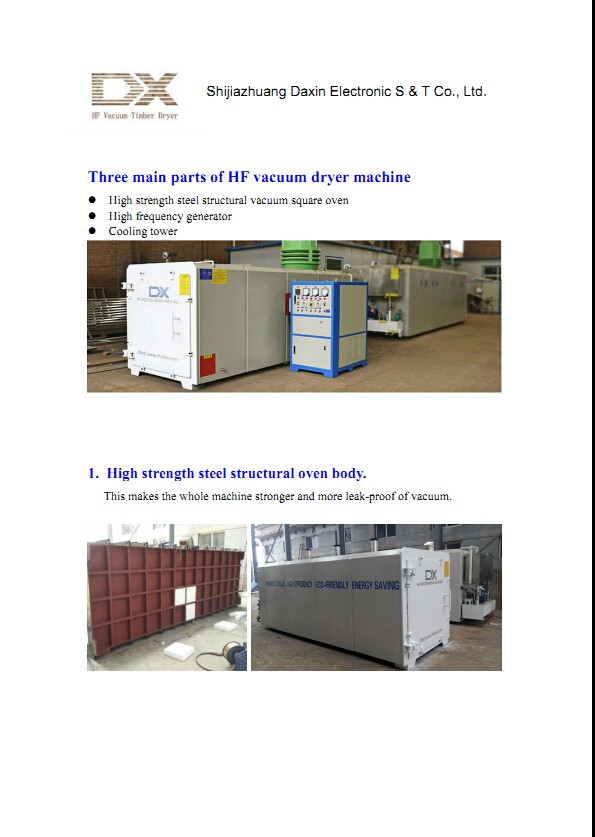

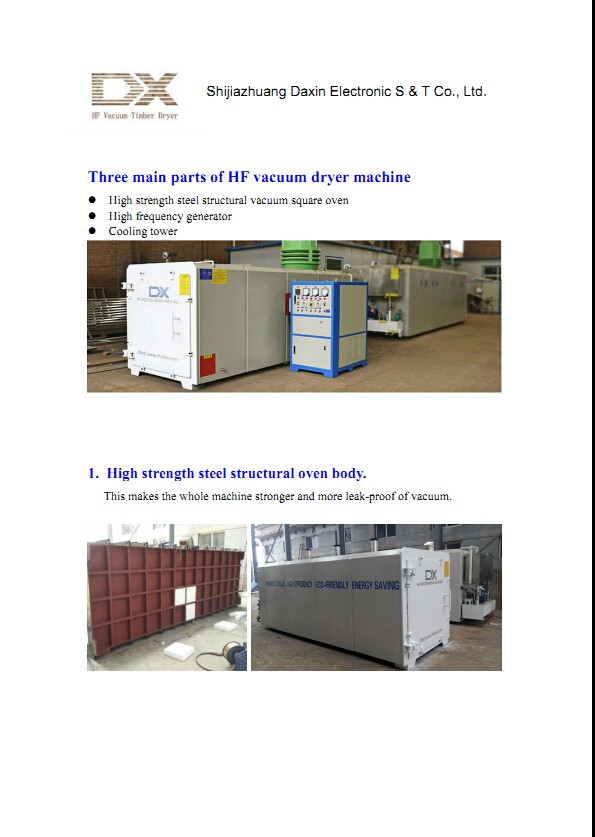

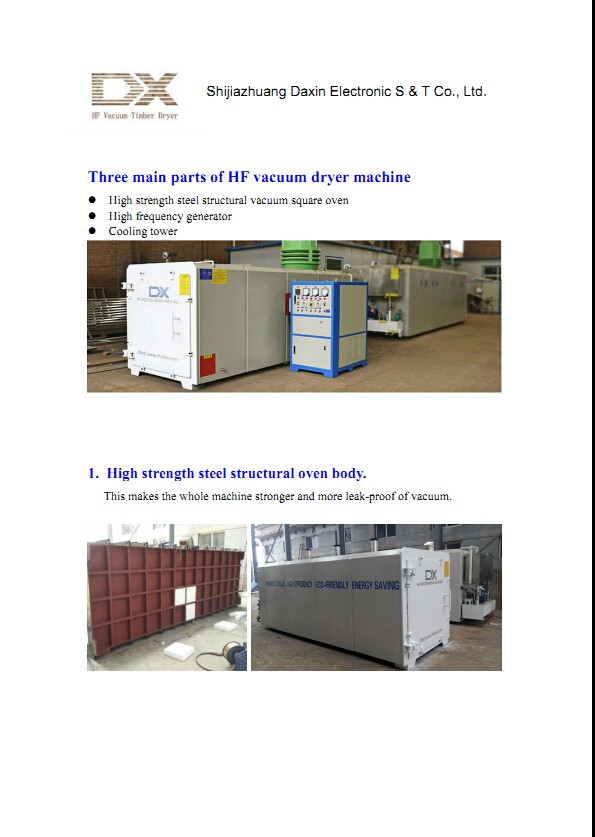

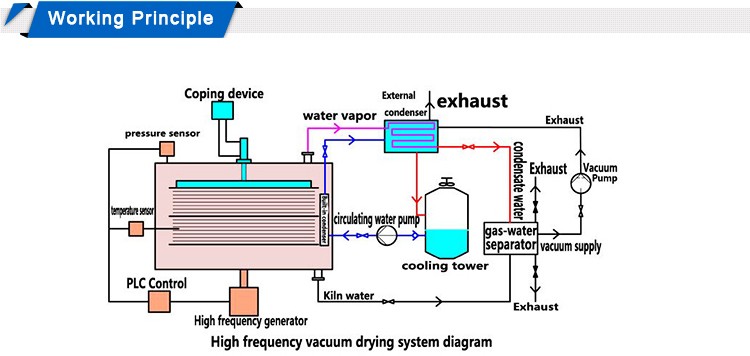

Machine Parts Name: High frequency generator This is the core parts of the machine ,all procedures and main technology are inside ,including PLC ,electric valve etc.

Machine Parts Name: High frequency generator This is the core parts of the machine ,all procedures and main technology are inside ,including PLC ,electric valve etc.

Main Features Name: Cooling tower

This part mainly used in hot weather ,the main usage is to cool the internal temperature,guarantee the drying speed and quality .

Machine Parts Name: Timber cart

Machine Parts Name: Timber cart

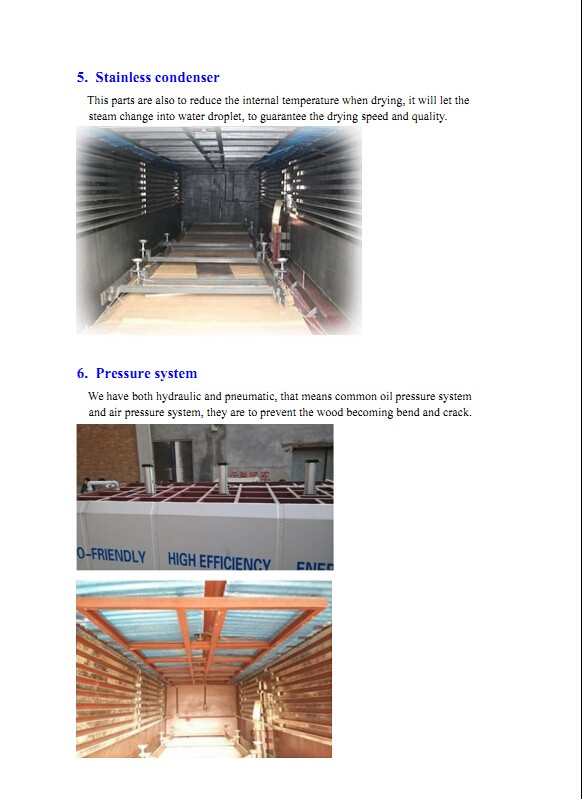

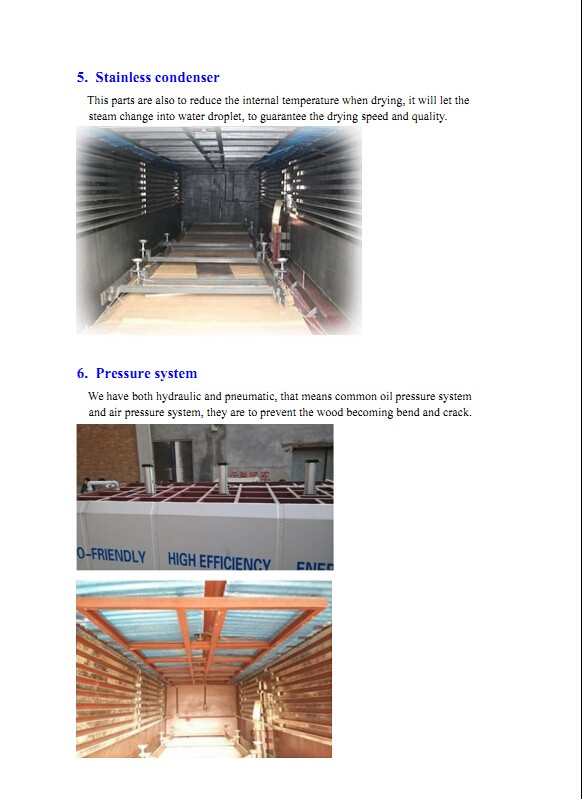

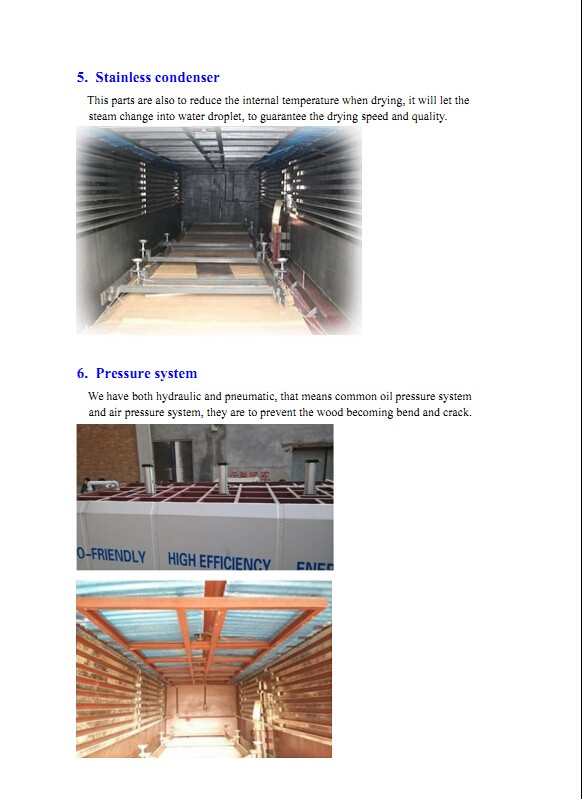

We have both full-auto mode and manual feeding model for your choose as your requests. Main Features Name: Stainless condenser

Inside glass fiber reinforced plastics, avoid the corrosion from the drying mositure of timber .

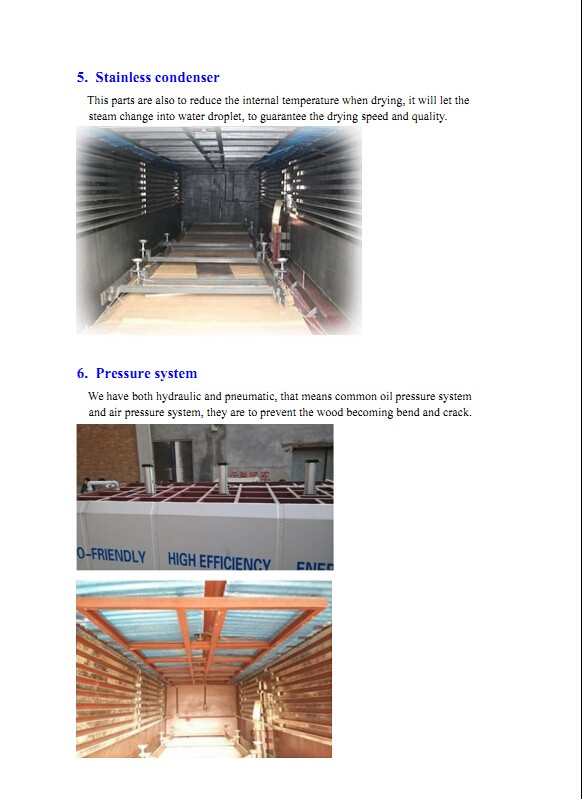

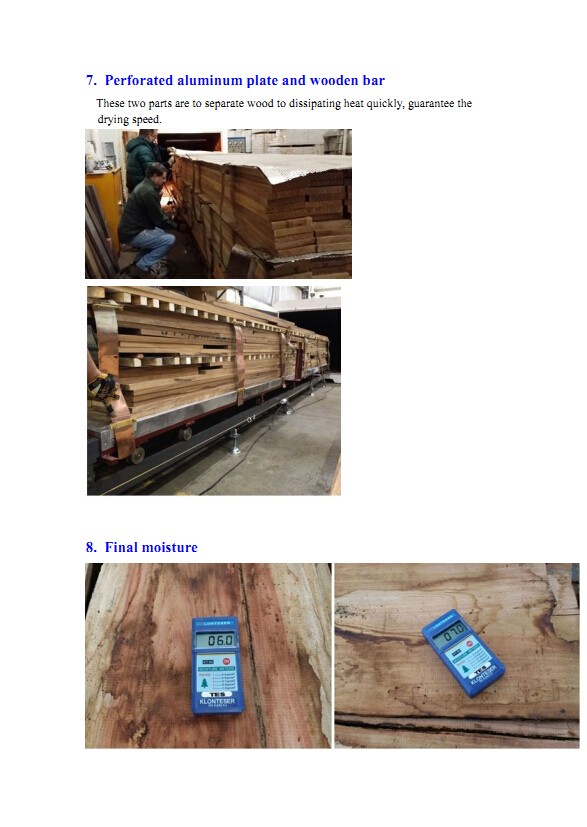

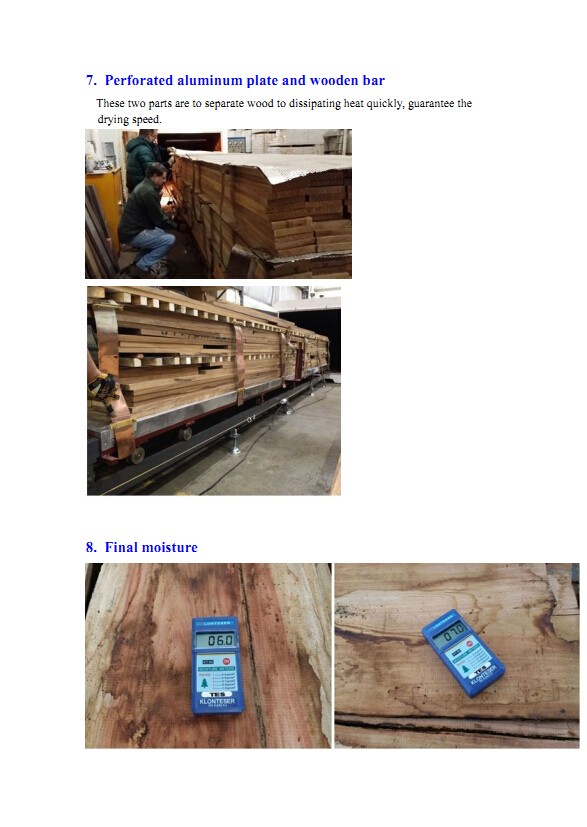

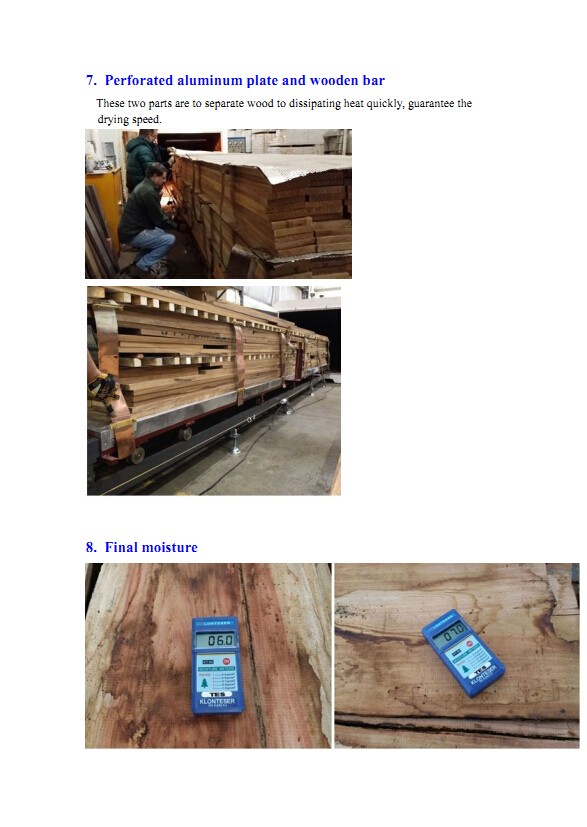

Machine parts Name: Pressure system We have both hydraulic and pneumatic ,that means common oil system and air pressure system ,thay are to prevent the wood bocoming bend and crack . Main features Name: Perforated aluminum plate and wooded bar These 2 parts are to seperate wood to dissipating heat quickly ,guarantee the drying speed.

Machine parts Name: Pressure system We have both hydraulic and pneumatic ,that means common oil system and air pressure system ,thay are to prevent the wood bocoming bend and crack . Main features Name: Perforated aluminum plate and wooded bar These 2 parts are to seperate wood to dissipating heat quickly ,guarantee the drying speed.

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Drying result testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Drying result testing support. * View our Factory. After-Sales Service

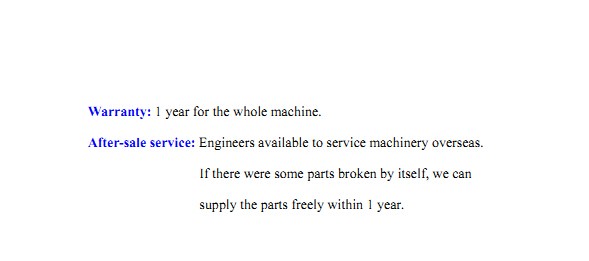

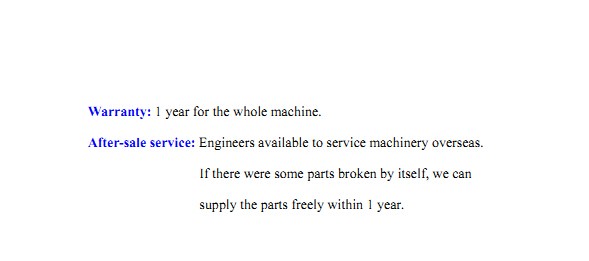

* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. Warrenty: all kinds of machines can be ensured 1 year.

Customer service: If there were something wrong during this warrenty, our engineer would be available to oversea to repair it freely.

Packing & Delivery Related Products

Related Products

Why us 1.Experienced team with considerate exporting and shipping service offering

Why us 1.Experienced team with considerate exporting and shipping service offering

2.No additional profits price, suppliers pay to become our members

3.As the third party inspection

4.Engineers available oversesa service

High frequency vacuum wood drying kiln is a new generation wood drying equipment.

This machine is the result of design combining high frequency medium heating technology and vacuum cryogenic dehydration technology, greatly reduced drying time.

1. To dry all kinds of wood in board or column type, slab type, cant type, timber type etc..

2. To dry all kinds of wood in veneer type.

3. To dry all kinds of wood in bending type.

Mary Email: haibo1 @vhaibo.com

Mob:+86-13663110303

Skype: vhaibo

Tel: +86-311-89836929; Fax: +86-311-86682328

Web:www.hfwoodworking.com

Features of High frequency vacuum wood dryer: Vacuum Drying — 60℃ starting to vaporize , which can reduce wood cracking and deformation while achieving low temperature drying

Features of High frequency vacuum wood dryer: Vacuum Drying — 60℃ starting to vaporize , which can reduce wood cracking and deformation while achieving low temperature dryingWarp Deformation Recovering --- Wood clamped by hydraulic system before drying, warping deformation to be recovered when soften , making outturn greatly improving and make easy palletizing

Quick Heating --- No need heat conduction, inside and outside of wood timber are heated at the same time

Fast Dehydration--- During the heating process, stepped temperature difference between inside and outside of wood can speed up the water movement from inside wood to outside wood

High Quality--- Avoid outside & inside cracking and color change, by taking control of heating speed, relative vacuum degree and condensing rate.

Good Adaptability---It can achieve both low temperature and high temperature drying, also can eliminate stress , solidify resin and apply to dry almost all kinds of wood

Full-automatic & Easy operation --- Automatic feeding and discharging device , drying proceeding under unattended mode

Cost Saving--- Low dry shrinkage and material saving

Sterilization function & Eco-friendly

Advantages of High frequency vacuum wood dryer

1)Heating fast and uniformly, fast drying(:more than10 times faster than conventional steam dryer);

2)Saving labor, cost and drying time;

3)Full-automatic, easy to control and operate; flexible and simple;

4)High outturn percentage, no crack, no deformation;

5)Environmental protection;

6)New square design tank increase the availability of the inner space;

7)Bacteria and worm killing, high outturn percentage ;

8)Drying apply for all kinds of wood

Machine Parts Name: High frequency generator This is the core parts of the machine ,all procedures and main technology are inside ,including PLC ,electric valve etc.

Machine Parts Name: High frequency generator This is the core parts of the machine ,all procedures and main technology are inside ,including PLC ,electric valve etc.Main Features Name: Cooling tower

This part mainly used in hot weather ,the main usage is to cool the internal temperature,guarantee the drying speed and quality .

Machine Parts Name: Timber cart

Machine Parts Name: Timber cartWe have both full-auto mode and manual feeding model for your choose as your requests. Main Features Name: Stainless condenser

Inside glass fiber reinforced plastics, avoid the corrosion from the drying mositure of timber .

Machine parts Name: Pressure system We have both hydraulic and pneumatic ,that means common oil system and air pressure system ,thay are to prevent the wood bocoming bend and crack . Main features Name: Perforated aluminum plate and wooded bar These 2 parts are to seperate wood to dissipating heat quickly ,guarantee the drying speed.

Machine parts Name: Pressure system We have both hydraulic and pneumatic ,that means common oil system and air pressure system ,thay are to prevent the wood bocoming bend and crack . Main features Name: Perforated aluminum plate and wooded bar These 2 parts are to seperate wood to dissipating heat quickly ,guarantee the drying speed.

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Drying result testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Drying result testing support. * View our Factory. After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. Warrenty: all kinds of machines can be ensured 1 year.

Customer service: If there were something wrong during this warrenty, our engineer would be available to oversea to repair it freely.

Packing & Delivery

Related Products

Related Products

Why us 1.Experienced team with considerate exporting and shipping service offering

Why us 1.Experienced team with considerate exporting and shipping service offering2.No additional profits price, suppliers pay to become our members

3.As the third party inspection

4.Engineers available oversesa service

Related Keywords

Related Keywords

You May Also Like

You May Also Like