Copprt shot blasting

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

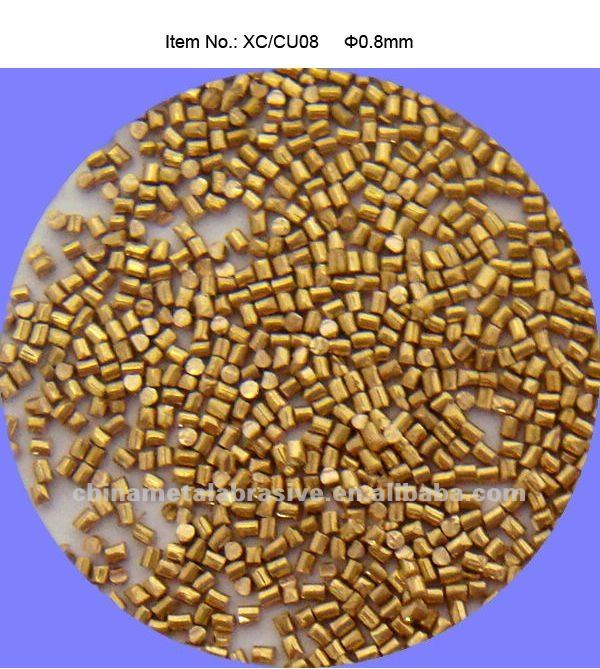

Specifications Copper shot blasting

1) Sizes: 0.5-3.5mm

2) Tensile Intensity:200~500Mpa

3) Durability:5000 Times

4) MOQ: 100kg, Sample free

Blasting media of copper shot Copper shot blasting Cu wire copper shot Copper shot Copper Cut Wire Shot Copper shot for blasting Brass shot blasting Brass cut wire shot Copper shot as cut Brass shot as cut Specs: SS-0.3, SS-0.6 SS-0.8 SS-1.0 SS-1.2 SS-1.4 SS-1.7 SS-2.0 SS-2.5 SS-3.0

material: new copper wire Advantage: 1. Copper Cut Wire Shot long life time 2. High-quality and competitive/best price 3. Ceritificate: ISO9001:2008, SAEJ4444 4. Density: 8.9 g/cm3 5. Hardness: 110~300HV 6. Less Dust 7. Shape: Cylindrical Usage: Surface cleaning, descaling, burr removing Main technical indicators of Copper cut wire shot:

Advantage: 1. Copper Cut Wire Shot long life time 2. High-quality and competitive/best price 3. Ceritificate: ISO9001:2008, SAEJ4444 4. Density: 8.9 g/cm3 5. Hardness: 110~300HV 6. Less Dust 7. Shape: Cylindrical Usage: Surface cleaning, descaling, burr removing Main technical indicators of Copper cut wire shot:

Application scope of copper cut wire shot: It is widely used in surface treatment such as descaling, burr removing, elimination of surface defects, internal stress relief, etching, matte finish, leveling, strengthening and rust prevention before applying in the metal die castings, precision castings, hardware & tools, machinery manufacturing, auto parts, instruments & meters, pumps and valves industries.

Any questions and inquirement, please feel free to contact me. Skye, is right here waiting for you! ^_^ Skype: skyeley

Any questions and inquirement, please feel free to contact me. Skye, is right here waiting for you! ^_^ Skype: skyeley

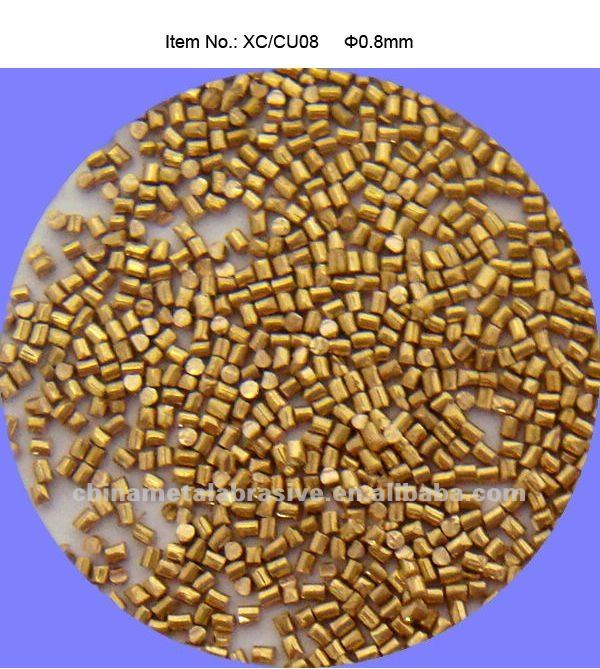

1) Sizes: 0.5-3.5mm

2) Tensile Intensity:200~500Mpa

3) Durability:5000 Times

4) MOQ: 100kg, Sample free

Blasting media of copper shot Copper shot blasting Cu wire copper shot Copper shot Copper Cut Wire Shot Copper shot for blasting Brass shot blasting Brass cut wire shot Copper shot as cut Brass shot as cut Specs: SS-0.3, SS-0.6 SS-0.8 SS-1.0 SS-1.2 SS-1.4 SS-1.7 SS-2.0 SS-2.5 SS-3.0

material: new copper wire

Advantage: 1. Copper Cut Wire Shot long life time 2. High-quality and competitive/best price 3. Ceritificate: ISO9001:2008, SAEJ4444 4. Density: 8.9 g/cm3 5. Hardness: 110~300HV 6. Less Dust 7. Shape: Cylindrical Usage: Surface cleaning, descaling, burr removing Main technical indicators of Copper cut wire shot:

Advantage: 1. Copper Cut Wire Shot long life time 2. High-quality and competitive/best price 3. Ceritificate: ISO9001:2008, SAEJ4444 4. Density: 8.9 g/cm3 5. Hardness: 110~300HV 6. Less Dust 7. Shape: Cylindrical Usage: Surface cleaning, descaling, burr removing Main technical indicators of Copper cut wire shot: Product Description | Copper Cut Wire Shot |

Chemical Composition | Cu: 58-99%, the rest is Zn |

Microhardness | 110~300HV |

Tensile Intensity | 200~500Mpa |

Durability | 5000 Times |

Microstructure | Deformed αorα+β |

Density | 8.9 g/cm3 |

Bulk Density | 5.1 g/cm3 |

Any questions and inquirement, please feel free to contact me. Skye, is right here waiting for you! ^_^ Skype: skyeley

Any questions and inquirement, please feel free to contact me. Skye, is right here waiting for you! ^_^ Skype: skyeley Related Keywords

Related Keywords