a519 4130 mechanical tubes/drill steel for drill tool/drill rods Delivery status: NBK(+N) BK(+C) BKW+(LC) BKS(SR) ASTM A519 Alloy Steel Pipe 44140 steel/aisi 4140 steel bar 4140 / 4130 Seamless Mechanical Tubing are medium carbon alloy grades, which are widely used for many general purpose applications that require high tensile strength and toughness. The addition of chromium and molybdenum as alloying elements, combined with heat treatment, provides the combined advantage of hardness, ductility, and strength. 4140 Meets ASTM A519 chromoly steel tube Cut to Length available Benefits of Round 4140/4130 Alloy Seamless Mechanical Tubing Superior tensile strength and toughness High strength to weight ratio - 4130/4140 hex tube/hex solid bars Easily heat treatable to a broad range of strength, machinability, and hardness. Applications: aircraft components, hydraulic cylinders, rollers, structural apps, truck and automotive parts. Heating Specifications AISI 4130 can be heated as a way to harden the material. When hardening is desired, the material should be heated at a minimum of 1600 degrees F. followed by an oil quench. The best results can be obtained when heating occurs between 1650 and 1700 degrees, followed by an oil quench and soak of 1600 degrees. If the material loses too much ductility during this process, the material can be tempered to restore some of the function. Tempering should be conducted at temperatures between 750 and 1050 degrees, depending on the resultant strength desired. The lower temperatures generally result in greater strengths during the tempering process. Heating can also be used to make the material easier to work with. Manipulation heating can be best conducted in a range of 2000 to 1500 degrees. 4130 chromoly steel

Seamless carbon and Alloy Steel Mechanical Tubing |

Application | For mechanical engineering.

For mechanical and pressure use,and also for transporting steam,water,gas and etc. |

Size(mm): | O.D.: 20∼180 W.T.: 2-30L: max 12000 |

aisi 4130 alloy steel - 4130/4140 hex tube/hex solid bars Grade and Chemical Composition (%) of 4130 pipe 4140 steel strength

Grade | C | Mn | P≤ | S≤ | Si | Cr | Mo |

1008 | ≤0.10 | 0.30-0.50 | 0.040 | 0.050 | - | - | - |

1010 | 0.08-0.13 | 0.30-0.60 | 0.040 | 0.050 | - | - | - |

1018 | 0.15-0.20 | 0.60-0.90 | 0.040 | 0.050 | - | - | - |

1020 | 0.18-0.23 | 0.30-0.60 | 0.040 | 0.050 | - | - | - |

1025 | 0.22-0.28 | 0.30-0.60 | 0.040 | 0.050 | - | - | - |

1026 | 0.22-0.28 | 0.60-0.90 | 0.040 | 0.050 | - | - | - |

4130 | 0.28-0.33 | 0.40-0.60 | 0.040 | 0.050 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

4140 | 0.38-0.43 | 0.75-1.00 | 0.040 | 0.050 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

Mechanical Properties of 4130 tube/4140 tube/ 4130/4140 hex tube/hex solid bars

Grade | Condition | MPa Tenslle Point | Yield Point | Elongation |

1020 | CW | ≥414 | ≥483 | ≥5% |

| SR | ≥345 | ≥448 | ≥10% |

| A | ≥193 | ≥331 | ≥30% |

| N | ≥234 | ≥379 | ≥22% |

1025 | CW | ≥448 | ≥517 | ≥5% |

| SR | ≥379 | ≥483 | ≥8% |

| A | ≥207 | ≥365 | ≥25% |

| N | ≥248 | ≥379 | ≥22% |

4130 | SR | ≥586 | ≥724 | ≥10% |

| A | ≥379 | ≥517 | ≥30% |

| N | ≥414 | ≥621 | ≥20% |

4140 | SR | ≥689 | ≥855 | ≥10% |

| A | ≥414 | ≥552 | ≥25% |

| N | ≥621 | ≥855 | ≥20% |

4140 / 4130 Seamless Mechanical Tubing are medium carbon alloy grades, which are widely used for many general purpose applications that require high tensile strength and toughness. The addition of chromium and molybdenum as alloying elements, combined with heat treatment, provides the combined advantage of hardness, ductility, and strength. 4140 Meets ASTM A519 4130 Meets ASTM A513 Type 5(DOM) A519 (CDS) Stocked Size Range: 0.250” – 15” OD; 0.035” – 2.00” wall thickness Stocked Lengths 8’-24’ Cut to Length available enefits of Round 4140/4130 Alloy Seamless Mechanical Tubing Superior tensile strength and toughness High strength to weight ratio kennametal Easily heat treatable to a broad range of strength, machinability, and hardness. Applications: aircraft components, hydraulic cylinders, rollers, structural apps, truck and automotive parts. kennametal tool kennametal cold drawn seamless ASTM A519 4130 steel tube for mechanical parts/drill steel Cold drawn machine unit for 4130 steel.4140 steel chromoly alloy pipe

Furnace for 4130 steel tube /4130 pipe heat treatment

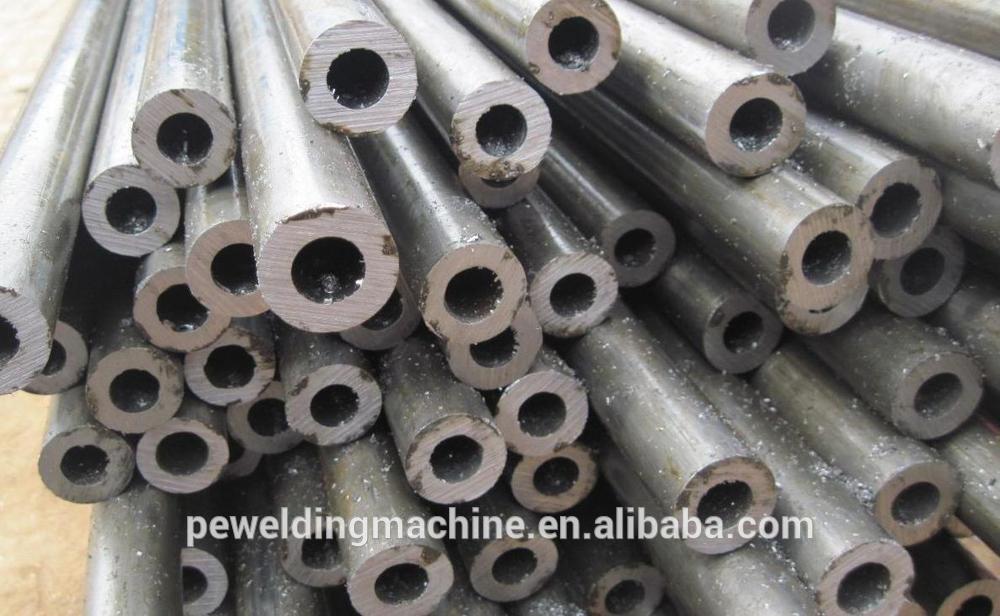

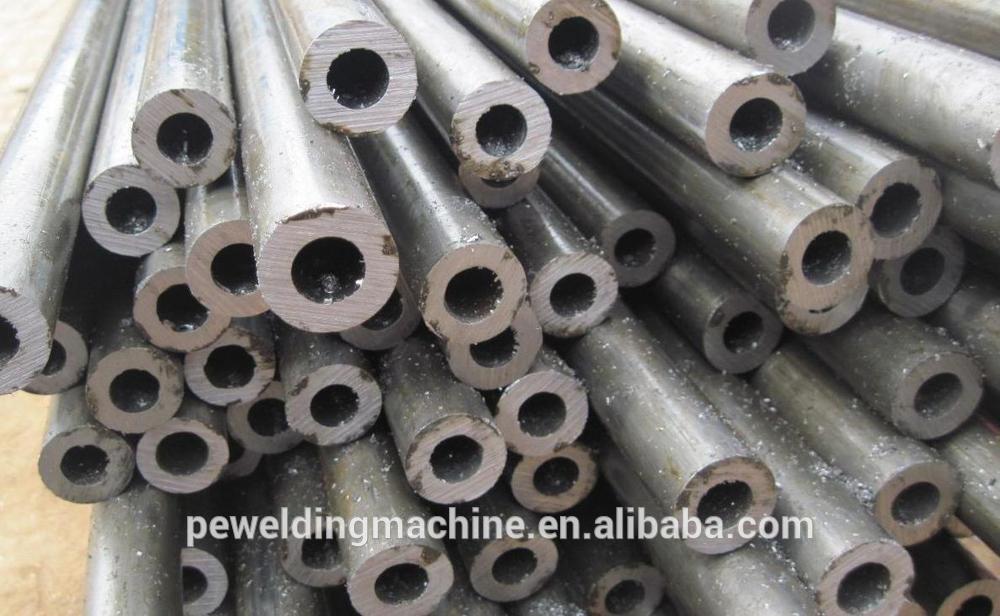

Cold drawn seamless pipe/4130 pipe /kenmaetal steel for drill rods

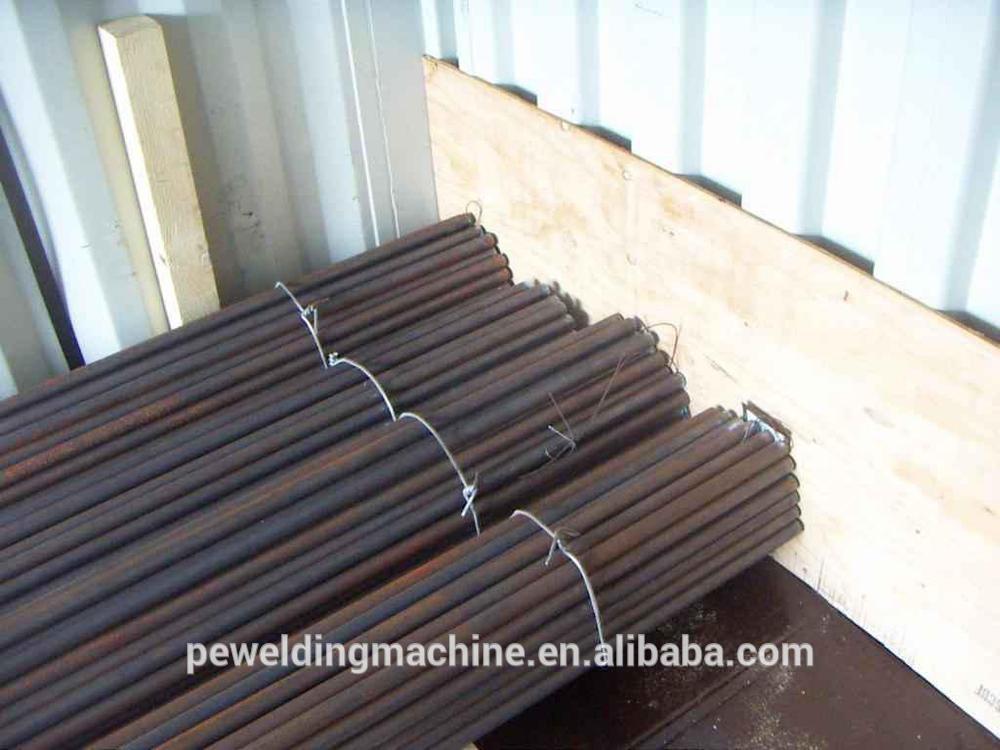

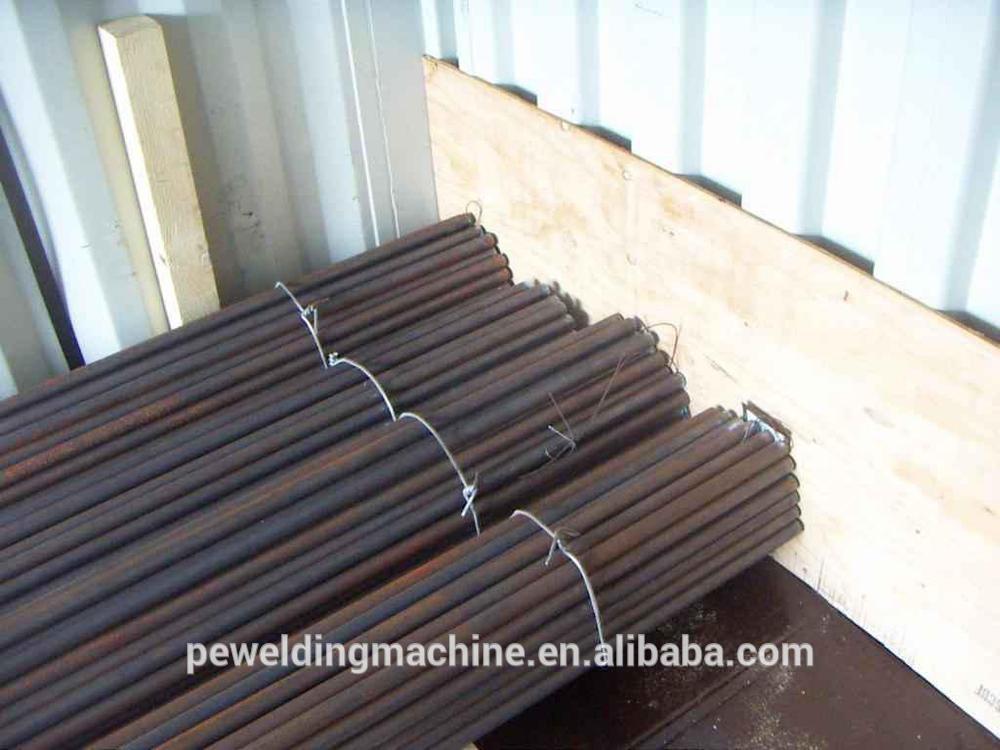

4130 tubing ship to U.S.A 4130 pipe for mechanical processing

Loading to container-4130 Steel tube for drill rod kennametal tool

Please contacut us for more details ! 4130/4140 hex tube/hex solid bars Contact Exp.Dep-- Mary Zhao

mary20150604

0086-183-3210-1998

mary(at)peweldingmachine.com

Furnace for 4130 steel tube /4130 pipe heat treatment

Furnace for 4130 steel tube /4130 pipe heat treatment  Cold drawn seamless pipe/4130 pipe /kenmaetal steel for drill rods

Cold drawn seamless pipe/4130 pipe /kenmaetal steel for drill rods  4130 tubing ship to U.S.A 4130 pipe for mechanical processing

4130 tubing ship to U.S.A 4130 pipe for mechanical processing Loading to container-4130 Steel tube for drill rod kennametal tool

Loading to container-4130 Steel tube for drill rod kennametal tool  Please contacut us for more details ! 4130/4140 hex tube/hex solid bars Contact Exp.Dep-- Mary Zhao

Please contacut us for more details ! 4130/4140 hex tube/hex solid bars Contact Exp.Dep-- Mary Zhao  mary20150604

mary20150604  0086-183-3210-1998

0086-183-3210-1998  mary(at)peweldingmachine.com

mary(at)peweldingmachine.com