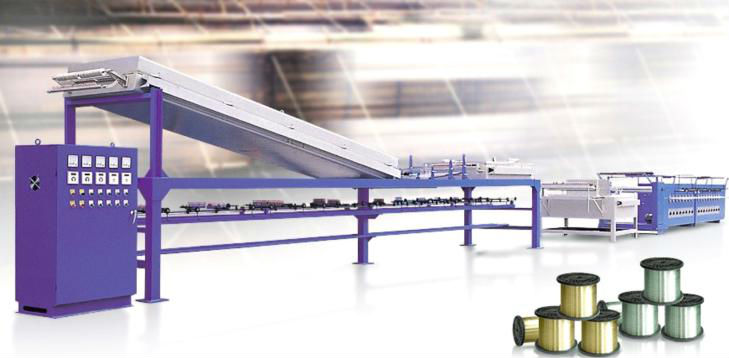

JD- 12H Bare copper wire tining machine

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

1,Applicable for: Φ0.2~0.3mm bare copper wire 2,Production rate: 250mm or as you needs 3,Diameter of outlet wire spool:Φ8-12cm bobbin size 4,Heating capacity of Tubular Softening furnace: 20kw 5,Heating capacity of Copper wire drying furnace:3KW 6.Power of single wheel-Guiding wheel: torque motor1.2-1.8NM 7Tension : 25kg.cm 8.Max. Branches :10 9.Cable way : cable speed controlled by single laid independent motors and stepless speed variator 10,Coiling manner : Double arrangement left and right 5 wires 11.Power of cable: 200W motor with 1 set of stepless speed variator 12.Voltage : 380V50HZ 13. inlet velocity of water: 20 litre / min 14.Tin tank capacity: 500kg

1,Applicable for: Φ0.2~0.3mm bare copper wire 2,Production rate: 250mm or as you needs 3,Diameter of outlet wire spool:Φ8-12cm bobbin size 4,Heating capacity of Tubular Softening furnace: 20kw 5,Heating capacity of Copper wire drying furnace:3KW 6.Power of single wheel-Guiding wheel: torque motor1.2-1.8NM 7Tension : 25kg.cm 8.Max. Branches :10 9.Cable way : cable speed controlled by single laid independent motors and stepless speed variator 10,Coiling manner : Double arrangement left and right 5 wires 11.Power of cable: 200W motor with 1 set of stepless speed variator 12.Voltage : 380V50HZ 13. inlet velocity of water: 20 litre / min 14.Tin tank capacity: 500kg Machine type | 12H/2m | 40H/4.5m | 40H/6m | 40H/8.5m | |||

No.of wires | 12 | 40 | 40 | 40 | |||

Length of annealing furnace | 2m | 4.5m | 6m | 8.5m | |||

Wire size | Φ0.03-Φ0.06mm | Φ0.10-Φ0.32mm | Φ0.10-Φ0.60mm | Φ0.30-Φ0.80mm | |||

Pay-off stand | Tension wire | Tension wire or overhead wire | |||||

Max.machine speed | 300m/min | ||||||

Tin-coating type | Single/double furnace hot coating | ||||||

Pay-off bobbin size | 250mm | Φ300mm or according to customers’requirements | |||||

Take-up bobbin size | K80-125mm | PT5-PT25 or according to customers’requirements | |||||

Take-up type | Single spooler drive AC motor/by torque motor | ||||||

Softening type | wire Continuous soften water seal /Nitrogen protection | ||||||

Total power consumption | 40KW | 70KW | 75KW | 85KW | |||

Machine dimension | 1200×1400×1200 | 20000×2000×1900 | 21000×2200×1900 | 24000×2400×1900 | |||

Traversing control | Decelerate motor, independent traversing | ||||||

Why let you choose us 1.Production experience:Absorbed ,Professional for 13years 2.Each link strict control the quality 3.Our goals are not do the lowest price to do the best quality 4. Life provides you with technical guidance 5. The long-term supply all kinds of spare parts, make sure that you use perennial 6. To offer our customers workshop design 7. Choose a professional supplier will bring you more convenient

Why let you choose us 1.Production experience:Absorbed ,Professional for 13years 2.Each link strict control the quality 3.Our goals are not do the lowest price to do the best quality 4. Life provides you with technical guidance 5. The long-term supply all kinds of spare parts, make sure that you use perennial 6. To offer our customers workshop design 7. Choose a professional supplier will bring you more convenient  Hengshui Jinda electromechanical Co., Ltd. Specializes in wire drawing machine, annealed wire machine and other drawing equipment accessories. Our company has strong technical support, including 3 senior engineers, 8 engineers and 100 skilled workers. The company can ensure product quality and reliable performance by advanced production technology

Hengshui Jinda electromechanical Co., Ltd. Specializes in wire drawing machine, annealed wire machine and other drawing equipment accessories. Our company has strong technical support, including 3 senior engineers, 8 engineers and 100 skilled workers. The company can ensure product quality and reliable performance by advanced production technology

We have strong technical force,senior engineers and technicians team,introduce the latest technology at home and abroad. We have a professional sale team with strict management, ready to fulfill your demand anytime.Our equipment well received in India,Egypt,Pakistan,Vietnam,Thailand,UZbekistan,Russian federation etc. We have more after-sale office in more than 20 provinces and cities in China and provide maintenance overseas.We are hoping to broaden our potential market all over the world.Looking forward to build a longterm partnership with you and with the efforts of both sides reach the goal of mutual benefits. Engineers for machine’s installation and debugging in Uzbekistan

We have strong technical force,senior engineers and technicians team,introduce the latest technology at home and abroad. We have a professional sale team with strict management, ready to fulfill your demand anytime.Our equipment well received in India,Egypt,Pakistan,Vietnam,Thailand,UZbekistan,Russian federation etc. We have more after-sale office in more than 20 provinces and cities in China and provide maintenance overseas.We are hoping to broaden our potential market all over the world.Looking forward to build a longterm partnership with you and with the efforts of both sides reach the goal of mutual benefits. Engineers for machine’s installation and debugging in Uzbekistan  Welcome to visit our factory and we have confident that we shall be your best supplier and partner in the future!

Welcome to visit our factory and we have confident that we shall be your best supplier and partner in the future! Related Keywords