hot sale automatic annealing machine for copper wire

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

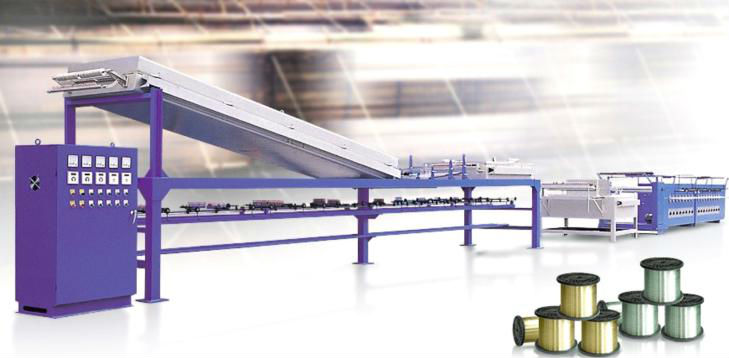

2014 hot sale 40H automatic annealing machine for copper wire

2014 hot sale 40H automatic annealing machine for copper wire 1. Usage: It is used to annealing and tinning copper wire from 0.1mm-0.7mm.

2. Main features: (1) Add one room inside the annealer, can make the temperature impartial distribution. (2) Dual tinning tank design, it can produce two kind of tin-coating copper wire in the same time. (3)Spooler arranged in double layer can save space. (4)It is energy-saving(good heat preservation effect) and high efficiency(low maintenance rate). 3. Technical parameter Continuous Annealing Tin-Coating Machine Features Add one room inside the annealer, can make the temperature impartial distribution. Dual tinning tank design, t can provide two kind of tin-coating copper wire in the same time. Spooler arranged in double layer can save space.

2. Main features: (1) Add one room inside the annealer, can make the temperature impartial distribution. (2) Dual tinning tank design, it can produce two kind of tin-coating copper wire in the same time. (3)Spooler arranged in double layer can save space. (4)It is energy-saving(good heat preservation effect) and high efficiency(low maintenance rate). 3. Technical parameter Continuous Annealing Tin-Coating Machine Features Add one room inside the annealer, can make the temperature impartial distribution. Dual tinning tank design, t can provide two kind of tin-coating copper wire in the same time. Spooler arranged in double layer can save space. Machine type | 12H/2m | 40H/4.5m | 40H/6m | 40H/8.5m | |||

No.of wires | 12 | 40 | 40 | 40 | |||

Length of annealing furnace | 2m | 4.5m | 6m | 8.5m | |||

Wire size | Φ0.03-Φ0.06mm | Φ0.10-Φ0.32mm | Φ0.10-Φ0.60mm | Φ0.30-Φ0.80mm | |||

Pay-off stand | Tension wire | Tension wire or overhead wire | |||||

Max.machine speed | 300m/min | ||||||

Tin-coating type | Single/double furnace hot coating | ||||||

Pay-off bobbin size | 250mm | Φ300mm or according to customers’requirements | |||||

Take-up bobbin size | K80-125mm | PT5-PT25 or according to customers’requirements | |||||

Take-up type | Single spooler drive AC motor/by torque motor | ||||||

Softening type | wire Continuous soften water seal /Nitrogen protection | ||||||

Total power consumption | 40KW | 70KW | 75KW | 85KW | |||

(mm) Machine dimension | 1200×1400×1200 | 20000×2000×1900 | 21000×2200×1900 | 24000×2400×1900 | |||

Traversing control | Decelerate motor, independent traversing | ||||||

Why let you choose us 1.Production experience:Absorbed ,Professional for 13years 2.Each link strict control the quality 3.Our goals are not do the lowest price to do the best quality 4. Life provides you with technical guidance 5. The long-term supply all kinds of spare parts, make sure that you use perennial 6. To offer our customers workshop design 7. Choose a professional supplier will bring you more convenient

Why let you choose us 1.Production experience:Absorbed ,Professional for 13years 2.Each link strict control the quality 3.Our goals are not do the lowest price to do the best quality 4. Life provides you with technical guidance 5. The long-term supply all kinds of spare parts, make sure that you use perennial 6. To offer our customers workshop design 7. Choose a professional supplier will bring you more convenient  Hengshui Jinda electromechanical Co., Ltd. Specializes in wire drawing machine, annealed wire machine and other drawing equipment accessories. Our company has strong technical support, including 3 senior engineers, 8 engineers and 100 skilled workers. The company can ensure product quality and reliable performance by advanced production technology

Hengshui Jinda electromechanical Co., Ltd. Specializes in wire drawing machine, annealed wire machine and other drawing equipment accessories. Our company has strong technical support, including 3 senior engineers, 8 engineers and 100 skilled workers. The company can ensure product quality and reliable performance by advanced production technology

Welcome to visit our factory and we have confident that we shall be your best supplier and partner in the future!

Welcome to visit our factory and we have confident that we shall be your best supplier and partner in the future! Related Keywords