Frothy Separation Slurry Pump

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 30 Sets per Month |

| Supply Ability: | 30 Sets per Month |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO |

| HS Code: | 84137099.90 |

| Transportation: | Ocean,Land |

Frothy Separation Frothy Slurry Pump

Introduction:

The SF (vertical froth pump, vertical frothy pump) is specifically designed for froth pumping. At the same time, we supply frothy slurry pump parts for these vertical froth pumps.

Advantages: Increased capacity through the pump system. Reduced spillage around the pump at high loads.

Function:

The tangential feed gives a strong vortex action in the conical tank, similar to the

function of a hydrocyclone.

The shear and centrifugal forces in this vortex breaks up (or destroys) the binding

between the air bubbles and the solids and separates free air and slurry.

The free air is released upwards along the centre shaft giving blockage free

performance.

The covered tank with its patented vortex finder increases performance and reduces

spillage.

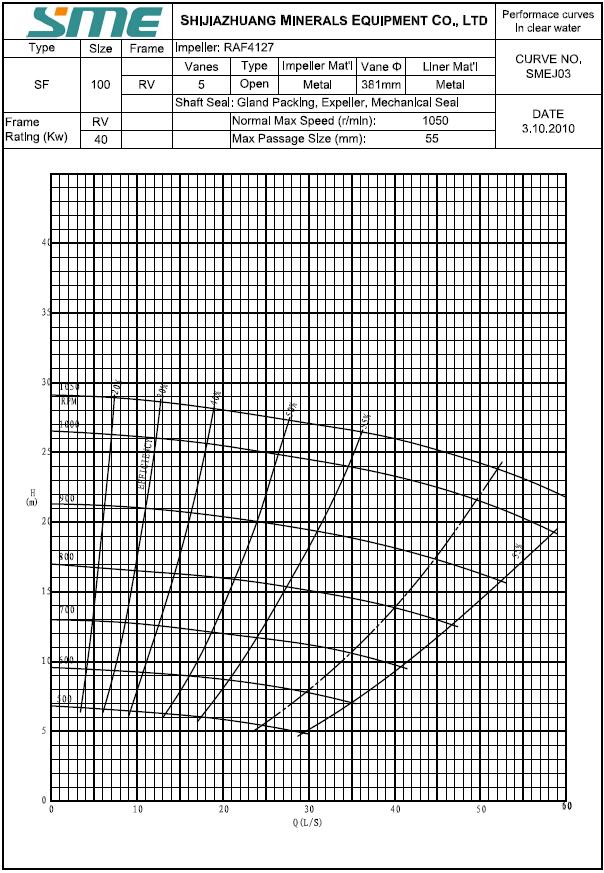

Specifications:

|

Model |

SF-100RV |

|

Discharge |

4-inch |

|

Capacity |

33-187.2m3/h |

|

TDH |

5-28m |

|

Rated Motor Power |

37Kw |

|

Speed |

500-1050r/min |

|

Max. Efficiency |

55% |

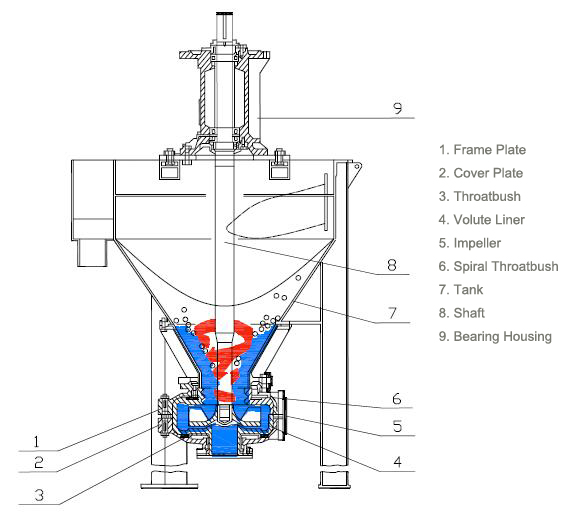

Construction of Froth Pump:

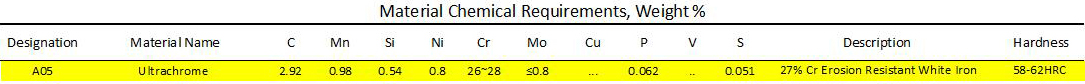

Materials of Construction:

|

Part Description |

Material |

|

Volute Liner |

A05- High Chromium Alloy |

|

Impeller |

A05- High Chromium Alloy |

|

Spiral Throatbush |

A05- High Chromium Alloy |

|

Casings |

Cast Iron |

|

Shaft |

Carbon Steel |

|

Tank |

Mild Steel |

Performance Curve:

Projects with Foam Pumps:

Related Keywords