Centrifugal Horizontal Double Frame Slurry Pump

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100 Sets per Month |

| Supply Ability: | 100 Sets per Month |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

Centrifugal Horizontal Double Frame Slurry Pump

Introduction:

A pump is both a pressure vessel and a piece of rotating equipment. All standard safetyprecautions for such equipment should be followed before and during installation, operation and maintenance. precautions for such equipment should be followed before and during installation, operation and maintenance. Pumps must not be operated at low or zero flow conditions for prolonged periods, or under any circumstances that could cause the pumping liquid to vaporise. Personnel injury and equipment damage could result from the high temperature and pressure created. Pumps must be used only within their allowable limits of pressure, temperature and speed. These limits are dependent on the pump type, configuration and materials used.

We supply not only bare shaft slury pump ends, but also electric motors, diesel enginens, accessories assembled together as a complete pumpset. This saves the customer a lot time to find suppliers of these equipment. We guarantee to our customers that you'll find quality slurry pumps, metal lined slurry pump, rubber lined slurry pump from SME, and you'll never regret for your decisions. All the pumps are selected based on the given specifications of the customer, to make sure every pump meet the requirement so that the pump will work without problems.

We've been exported our slurry pumps, slurry pump parts and complete slurry pumpsets to over 40 countries and regions around the world. We win our customers` trust and get a good reputation by our perfect quality guarantee and good sales service. Our slurry pumps are used for various industrial sectors, and they can be used as mine tailings slurry pumps, kaolin clay slurry pumps, and even glass fibers slurry pumps.

With low lead times and attentive customer service, SME is a recognized supplier in slurry pump manufacturing, pump repairs, pump remanufacturing and quality replacement slurry pump parts.

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

Specifications of Metal Lined Slurry Pump SH/50C:

|

Model |

SH-50CC |

|

Outlet |

2-inch |

|

Capacity |

39.6-86.4m3/h |

|

TDH |

12-64m |

|

Rated Motor Power |

55Kw |

|

Speed |

1300-2700r/min |

|

NPSH |

4-6m |

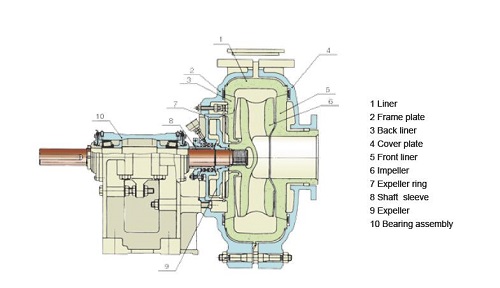

Construction of Metal Lined Slurry Pump:

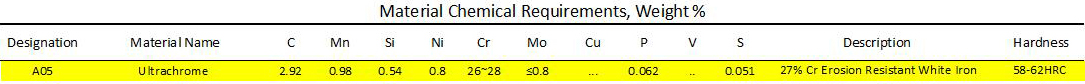

Standard Material of Wet-end Parts: Hi-Chrome Alloy A05

Typical Applications:

Tailings

Heavy Mining

Ash Handling

Cyclone Feeds

Pulp and Paper

Abrasive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Heavy Refusal Removal

Specifications of SH Series Slurry Pumps:

|

Pump Model |

S×D (inch) |

Allowable Max. Power (kw) |

Material | Clear Water Performance | Impeller | ||||||

| Capacity Q |

Head H(m) |

Speed n(r/min) |

Max.Eff. η% |

NPSH (m) |

No. of Vanes |

Vane Dia. (mm) |

|||||

| Impeller | m3/h | l/s | |||||||||

| SH/25B | 1.5×1 | 15 |

Metal (A05) |

12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 5 | 152 |

| SH/40B | 2×1.5 | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 | ||

| SH/50C | 3×2 | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 | ||

| SH/50CC | 3×2 | 55 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 | ||

| SH/75C | 4×3 | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 | ||

| SH/75D | 4×3 | 60 | 245 | ||||||||

| SH/100D | 6×4 | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 | ||

| SH/100E | 6×4 | 120 | 365 | ||||||||

| SH/150E | 8×6 | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 | ||

| SH/150F | 8×6 | 260 | 510 | ||||||||

| SH/150R | 8×6 | 300 | 510 | ||||||||

| SH/200F | 10×8 | 260 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 | ||

| SH/200ST | 10×8 | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 | ||

| SH/250F | 12×10 | 260 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 | ||

| SH/250ST | 12×10 | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 | ||

| SH/300ST | 14×12 | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 | ||

| SH/350TU | 16×14 | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1067 | ||

Projects with Slurry Pump:

Related Keywords