Solid Transport Rubber Lined Slurry Pump

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Shanghai, Beijing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100 Sets per Month |

| Supply Ability: | 100 Sets per Month |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO/CE |

| HS Code: | 84137099.90 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Shanghai,Beijing |

Solid Transport Rubber Lined Slurry Pump

Introduction:

The SHR rubber centrifugal pump has been designed for quick and easy maintenance. The rubberized pump is ideal for transfer of solids of pH value from 2 to 4. The flow parts can be changed from rubber spares to metal spares.

The SME SHR Rubber-Lined Series features a split-casing design with molded, replaceable rubber liners. The molded liner may be specified in a variety of natural and synthetic rubbers. Natural gum rubber is standard. The liners offer a shore-A hardness of 30-40 with a tensile strength minimum of 2,700 psi (18 n/mm2). Double-wall construction with an outer grey-iron casing and inner molded-rubber liners. Rubber lined pumps are mainly used for cossosive slurries with pH value 2-5, and they are also used to pump silicon sand, and are used in glass factories.

The heavy duty rubber lined slurry pumps produced by SME are qualified, reliable to the customers from all over the world. We have very successful cases with our customers using the rubber pumps SHR-100E and SHR-150E for quarries, and rubber pump SHR-40B, SHR-75C for gold separation plants.

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

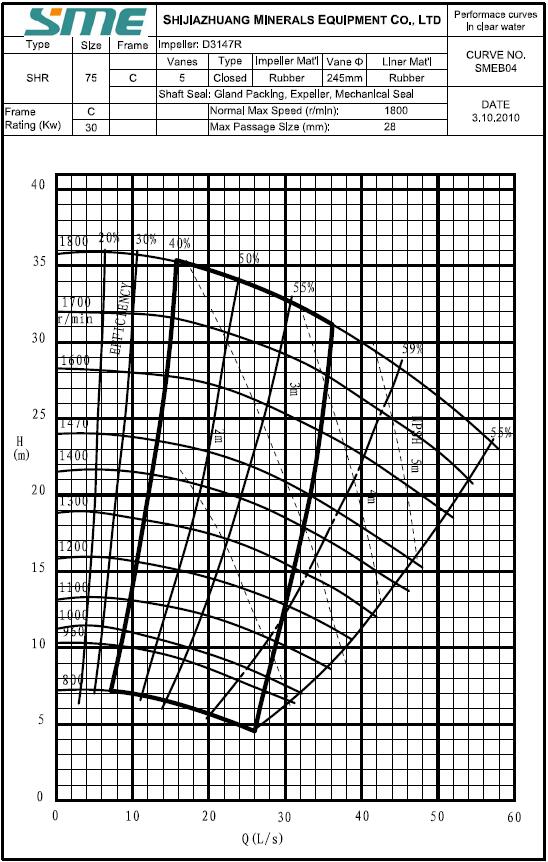

Specifications:

|

Model |

SHR-75C |

|

Outlet |

3-inch |

|

Capacity |

79.2-180m3/h |

|

TDH |

5-34.5m |

|

Rated Motor Power |

30Kw |

|

Speed |

800-1800r/min |

|

NPSH |

3-5m |

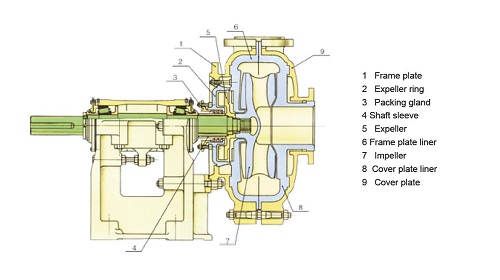

Construction of SHR Rubber Pumps:

Typical Applications:

Tailings

Heavy Mining

Ash Handling

Cyclone Feeds

Pulp and Paper

Corrosive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Heavy Refusal Removal

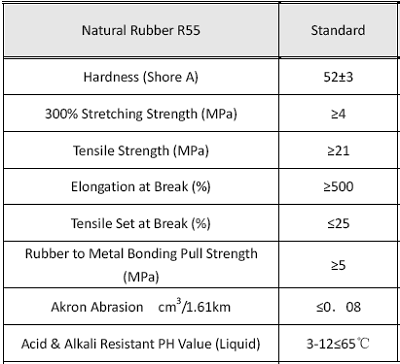

Standard Material of Wet-end Parts: Natural Rubber R55

Performance Curve:

Projects with SHR Rubber Pumps:

Related Keywords