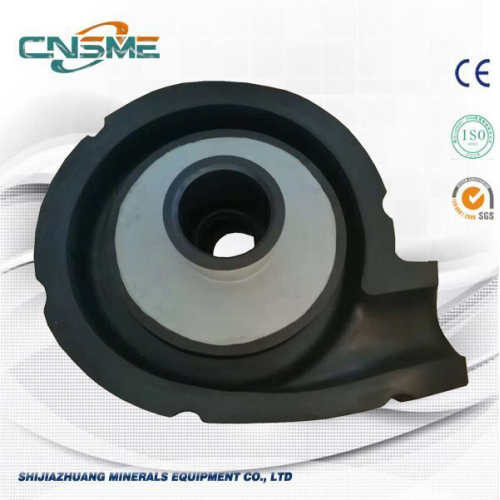

Corrosion Resistant Rubber Pump Parts

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100 Pcs per Month |

| Supply Ability: | 100 Pcs per Month |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air |

Corrosion Resistant Rubber Pump Parts

Introduction:

Rubber wet-end spare parts include impeller, cover plate liner, frame plate liner and throatbush. For the impeller, deep side sealing vanes relieve seal pressure and minimize recirculation. Cast-in impeller threads are better suited for slurries. The hard metal and moulded elastomer liners are interchangeable. There are three shaft sealing types as well for the rubber lined slurry pumps: expeller ring seal, gland packing seal and mechanical seal.

SHR series slurry pumps have a removable lining of wear-resistant rubber slurry pump parts. Slurry pump parts (Impeller and lining) are made of wear-resistant natural rubber. Rubber lined slurry pumps with rubber lining are better to use in aggressive environments. Soft surface readily absorbs blows particles.

Slurry pump parts cover Plate Liner is the front rubber liner on a rubber lined slurry pump. For small rubber lined slurry pumps, the front liner is casted together with the throatbush, whereas for rubber lined slurry pumps like size 6/4 and bigger, the front cover liners will be separately casted from the throatbush. Thus, there are three parts that consist of the wetted parts for smaller rubber lined slurry pumps, but there are four for bigger rubber lined slurry pump models.

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

Construction of Rubber Lined Slurry Pumps:

Rubber Lined Slurry Pump Application:

|

Pump Model |

S×D (inch) |

Allowable Max. Power (kw) |

Material | Clear Water Performance | Impeller | ||||||

| Capacity Q |

Head H(m) |

Speed n(r/min) |

Max.Eff. η% |

NPSH (m) |

No. of Vanes |

Vane Dia. (mm) |

|||||

| Impeller | m3/h | l/s | |||||||||

| SHR/25B | 1.5×1 | 15 |

Rubber (R55) |

10.8-25.2 | 3-7 | 7-52 | 1400-3400 | 35 | 3 | 152 | |

| SHR/40B | 2×1.5 | 15 | 25.2-54 | 7-15 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 5 | 178 | |

| SHR/50C | 3×2 | 30 | 36-75.6 | 10-21 | 13-39 | 1300-2100 | 2-4 | 213 | |||

| SHR/75C | 4×3 | 30 | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 | ||

| SHR/75D | 4×3 | 60 | 245 | ||||||||

| SHR/100D | 6×4 | 60 | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | 365 | ||

| SHR/100E | 6×4 | 120 | 365 | ||||||||

| SHR/150E | 8×6 | 120 | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 510 | ||

| SHR/150F | 8×6 | 260 | 510 | ||||||||

| SHR/150R | 8×6 | 300 | 510 | ||||||||

| SHR/200F | 10×8 | 260 | 540-1188 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | 686 | ||

| SHR/200ST | 10×8 | 560 | 540-1188 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | 686 | ||

| SHR/250F | 12×10 | 260 | 720-1620 | 320-700 | 13-14 | 300-500 | 79 | 3-8 | 762 | ||

| SHR/250ST | 12×10 | 560 | 720-1620 | 320-700 | 13-14 | 300-500 | 79 | 3-8 | 762 | ||

| SHR/300F | 14×12 | 260 | 1152-2520 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 965 | ||

| SHR/300ST | 14×12 | 560 | 1152-2520 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 965 | ||

Related Keywords