T series Spiral Bevel Gearbox (1:1 ratio 90 degree gearbox)

- Delivery Time:

- 20 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China (Mainland) |

|---|

Product Description

Product Description

T series Spiral Bevel Gearbox ( 1:1 ratio 90 degree gearbox ) Product Description

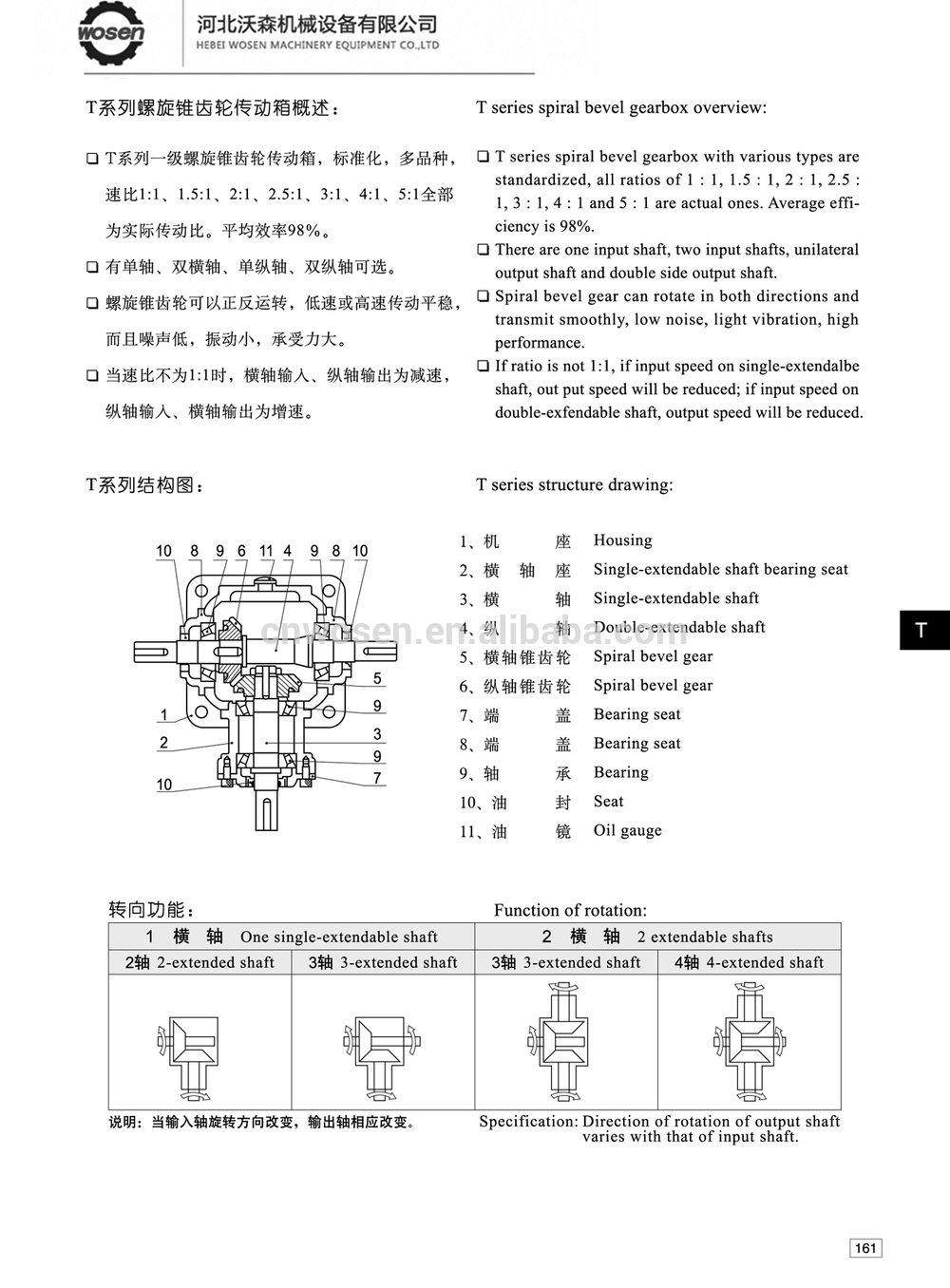

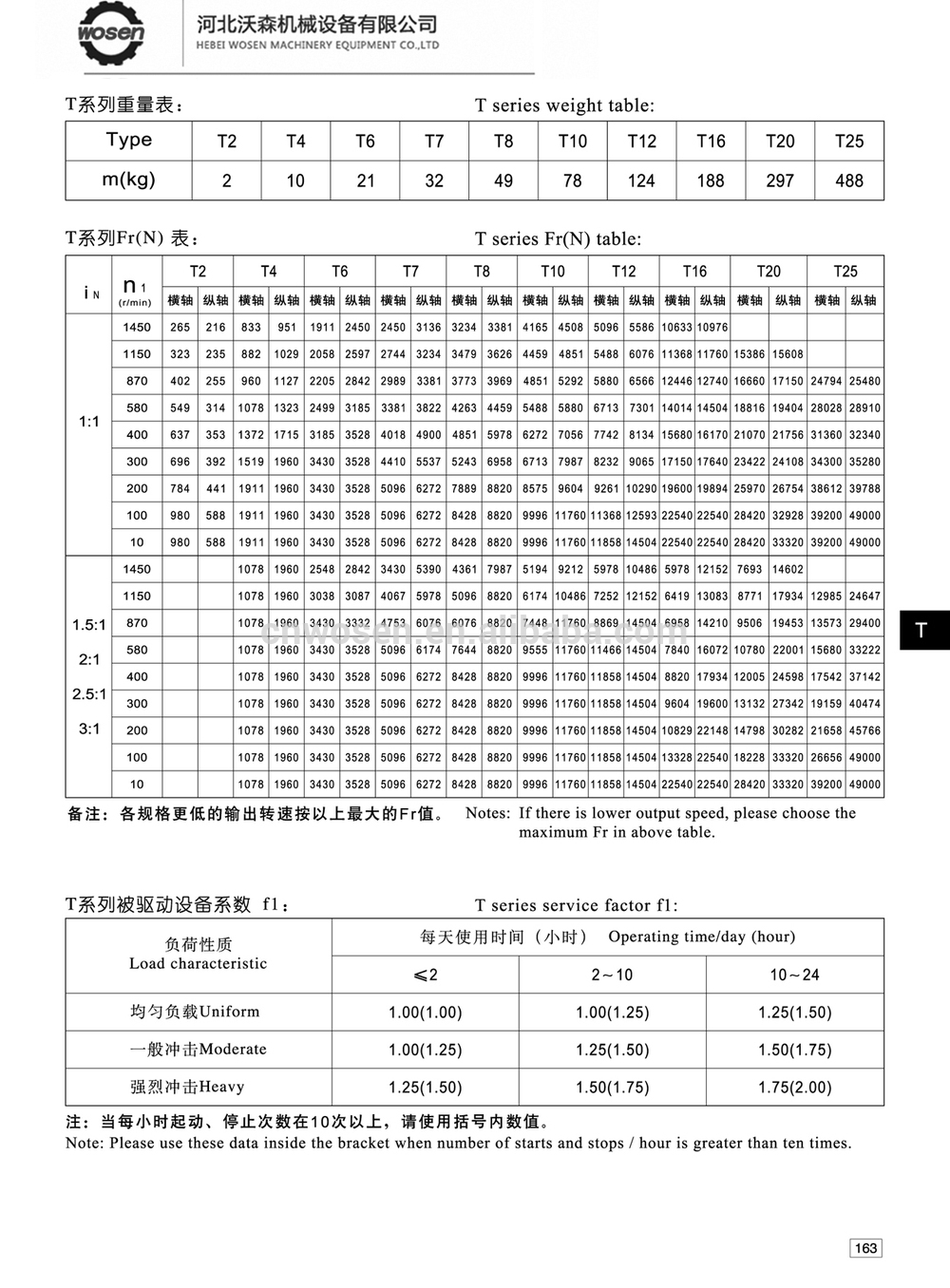

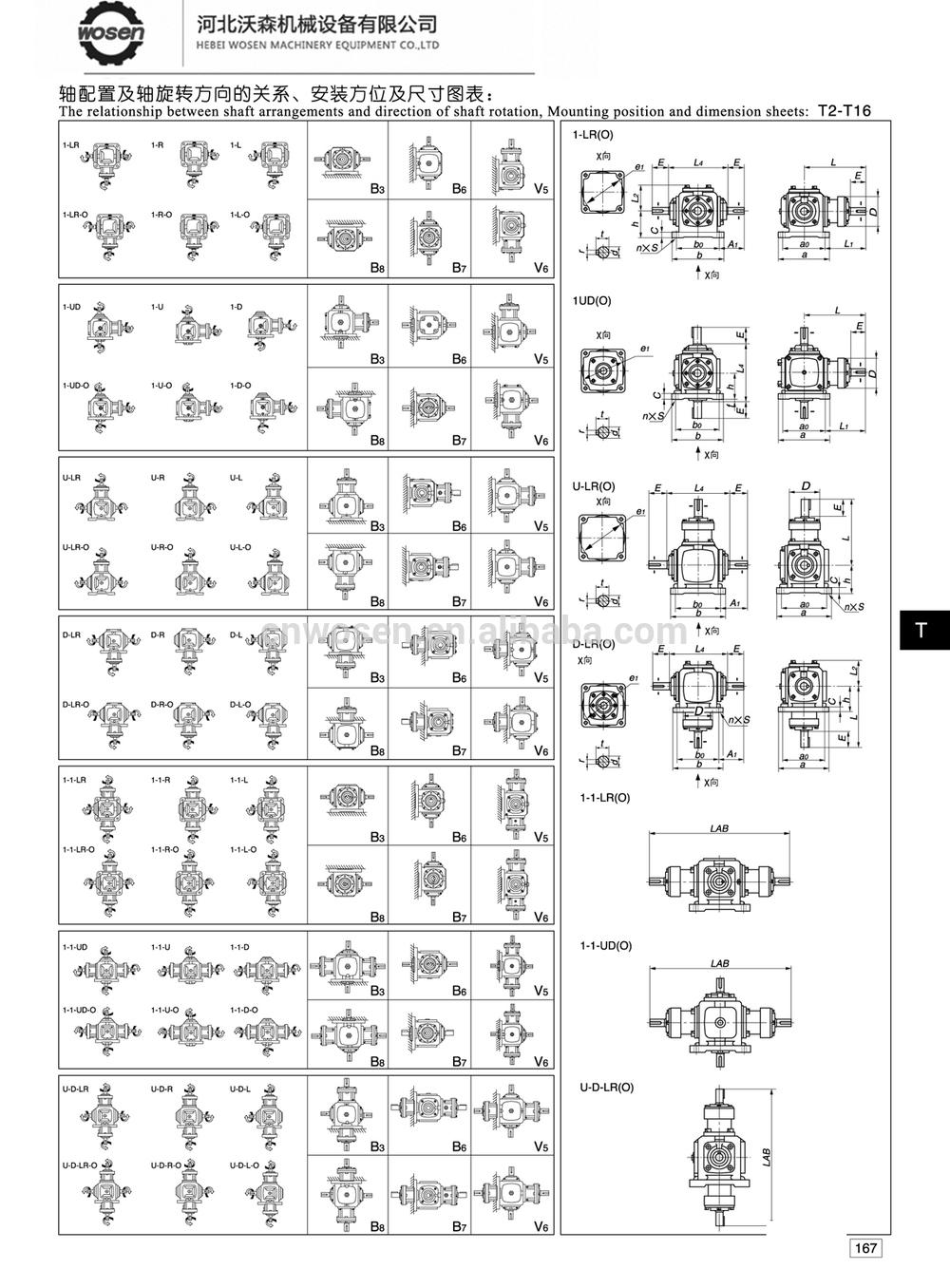

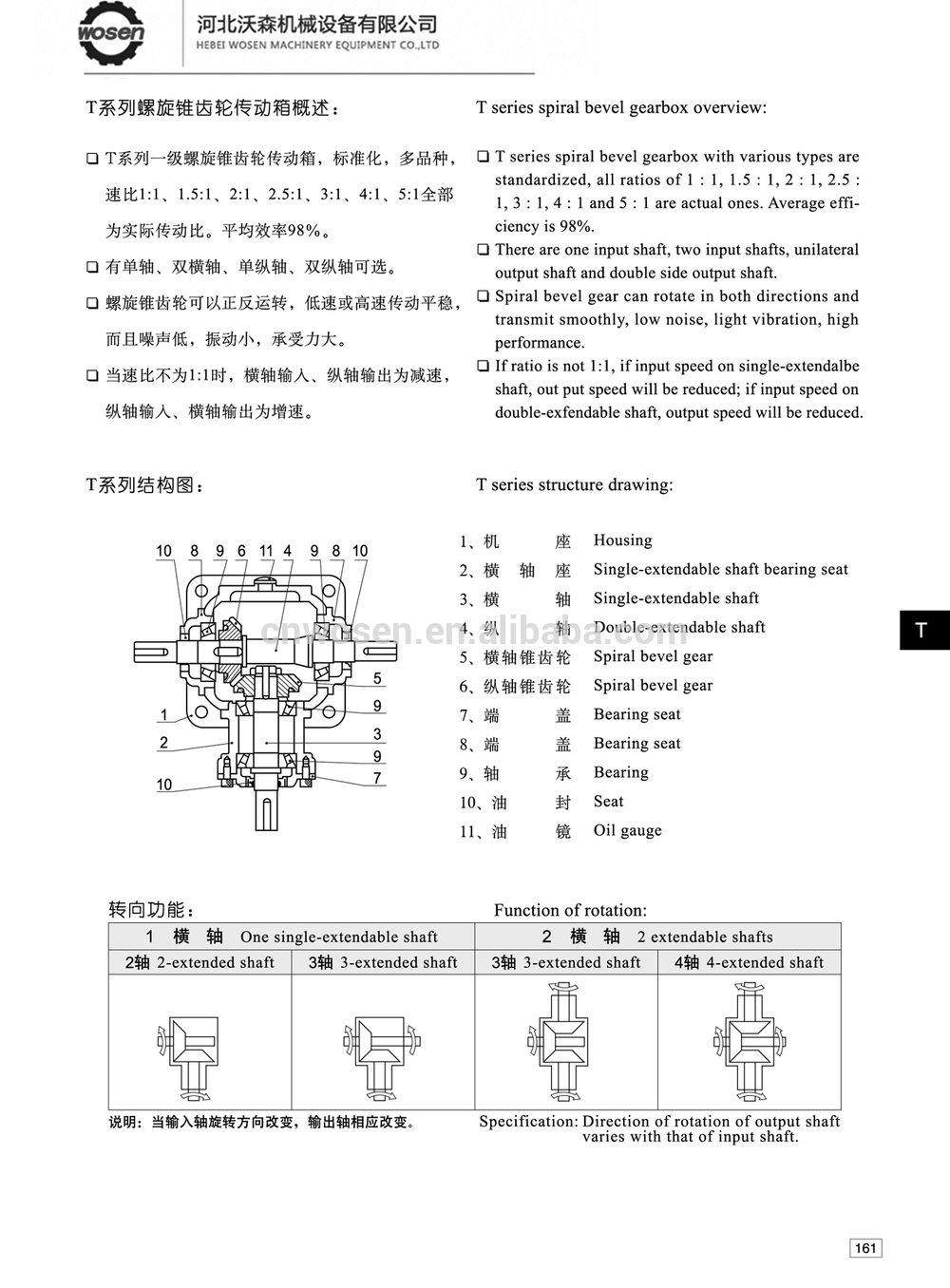

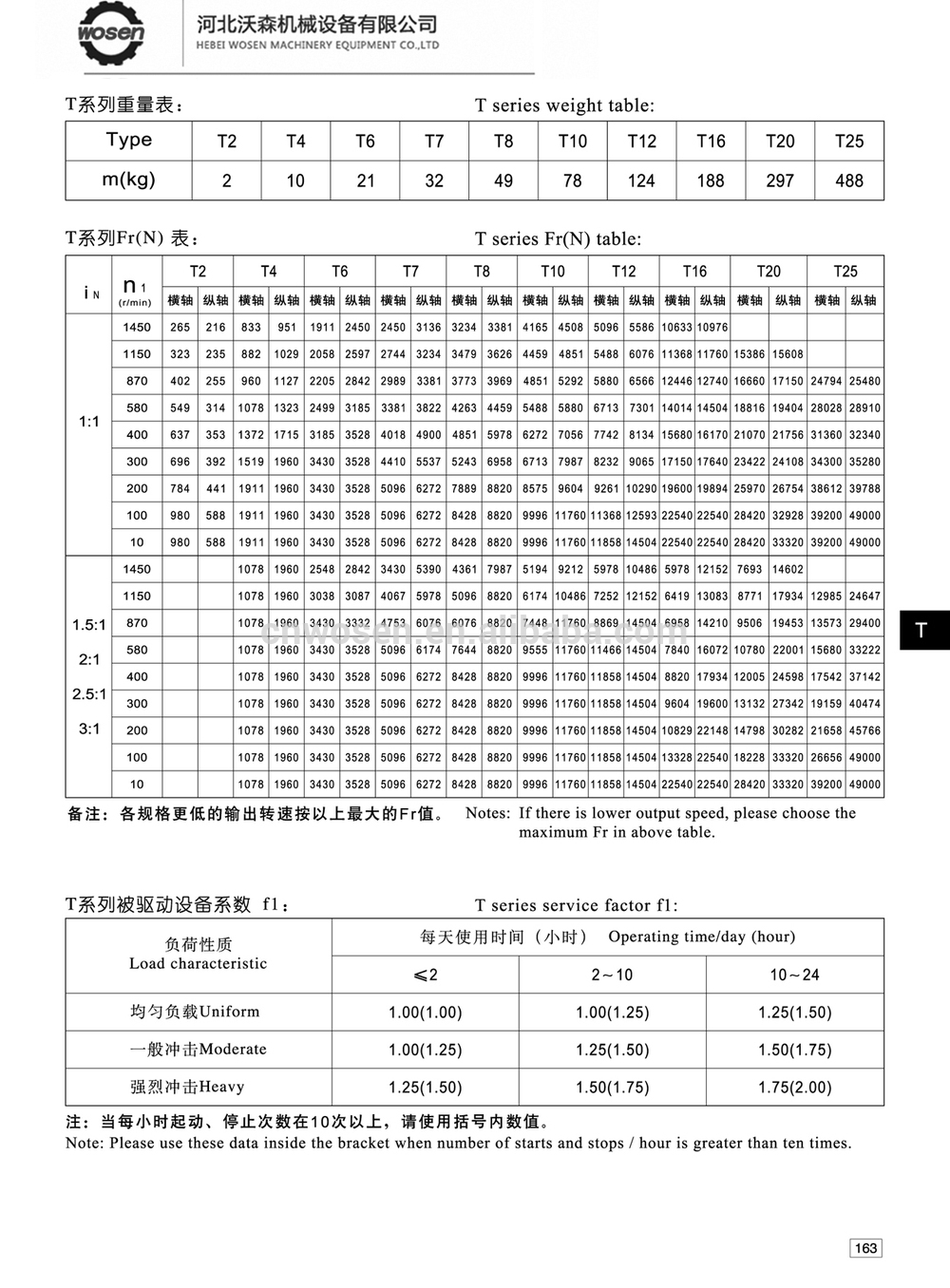

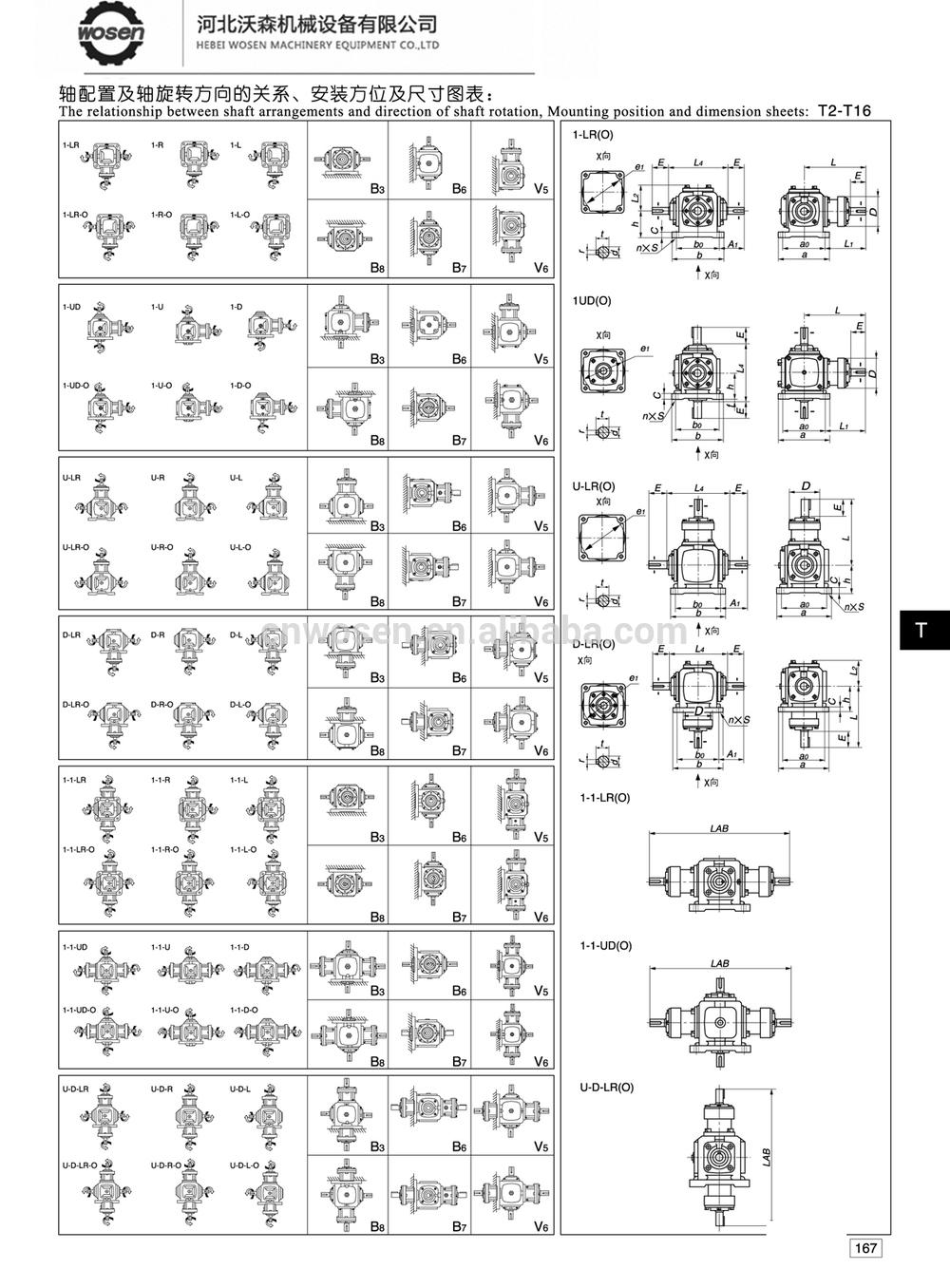

T Series Right Angle Bevel Gearbox / 1:1 ratio 90 degree gearbox Product overview: T series of a spiral bevel gear steering box, standardization, variety. 1:1 ratio, 1.5:1, 2:1, 2.2:1, 3:1, 4:1, 5:1 is the actual ratio. Steering function of single, double, single longitudinal axis transverse, longitudinal optional double. Spiral bevel gear steering box can be both positive and negative operation, high speed and low speed are stable operation, and low noise, vibration small, large carrying capacity. Product features: 1. Shell: high rigidity of the FC-25 cast iron casting; 2. Gear: gear with high purity alloy steel 20CrMnTiH quenched processing, carburizing quenching and grinding; 3. Main: shaft made of alloy steel quenching and tempering process, with the heavy load capacity; Bearing: tapered roller bearing with heavy load capacity; 4. Oil seal: with oil seal lip, ability has dustproof and oil leak-proof high; Models: T 2, 4, 6, 7, 8, 10, 12, 16, 20, 25 T series gear unit is a new gear commutator designed & manufactured by bevel gear(hard gear) transmission principle. 1. High mechanical efficiency: 98% (depends on the transmission steps); 2. Input form: shaft input; 3. Materials of gear unit body: HT250 high-strength cast iron; 4. Materials of shafts:42CrMo alloy steel; 5. Materials of gears : 20CrMnTi alloy steel; 6. Heat treatment: tempering, cementiting, quenching; 7. Surface hardness of gears: HRC58°-62 °; 8. Maching precision of gears: 6-5GRADE; 9. Brand of bearings: HRB, LYC,ZWZ,NSK; 10. Noise of gear unit: 60-68dB.

T Series Right Angle Bevel Gearbox / 1:1 ratio 90 degree gearbox Product overview: T series of a spiral bevel gear steering box, standardization, variety. 1:1 ratio, 1.5:1, 2:1, 2.2:1, 3:1, 4:1, 5:1 is the actual ratio. Steering function of single, double, single longitudinal axis transverse, longitudinal optional double. Spiral bevel gear steering box can be both positive and negative operation, high speed and low speed are stable operation, and low noise, vibration small, large carrying capacity. Product features: 1. Shell: high rigidity of the FC-25 cast iron casting; 2. Gear: gear with high purity alloy steel 20CrMnTiH quenched processing, carburizing quenching and grinding; 3. Main: shaft made of alloy steel quenching and tempering process, with the heavy load capacity; Bearing: tapered roller bearing with heavy load capacity; 4. Oil seal: with oil seal lip, ability has dustproof and oil leak-proof high; Models: T 2, 4, 6, 7, 8, 10, 12, 16, 20, 25 T series gear unit is a new gear commutator designed & manufactured by bevel gear(hard gear) transmission principle. 1. High mechanical efficiency: 98% (depends on the transmission steps); 2. Input form: shaft input; 3. Materials of gear unit body: HT250 high-strength cast iron; 4. Materials of shafts:42CrMo alloy steel; 5. Materials of gears : 20CrMnTi alloy steel; 6. Heat treatment: tempering, cementiting, quenching; 7. Surface hardness of gears: HRC58°-62 °; 8. Maching precision of gears: 6-5GRADE; 9. Brand of bearings: HRB, LYC,ZWZ,NSK; 10. Noise of gear unit: 60-68dB.

Related Keywords

Related Keywords

You May Also Like

You May Also Like

-

ZLY315 gear box hardened gear reducer, gear case heavy-duty reducer

GH/GV22 helical gearbox series fully enclosed large ratio gear box gear ratio range of 30: 1 to 50: 1 gear motor integrated

G18 helical gearbox series fully enclosed large ratio gear box gear ratio range of 30: 1 to 50: 1 gear motor integrated

G18/G22/G28/G32/G40/G50 series gear box/rigid tooth gearbox/high speed gearbox

Y2 series three phase motor manufacture