Helical Preformed Fitting Dead-End Grip For ADSS/OPGW/ACSR By HUANENG

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Specifications a. Excellent Quality

b. Competitive Price

c. Simple Installation

d. Good Corrosion Resistance

e. Best Service

1.Specification: a) There is a large contact area between the wire clamp and the conducting wires, The stress distribution is uniform, No stress concentration point, Make sure the fiber optic cable is well protected. b) High-quality aluminum clad material, To improve the mechanical properties of the clamp and corrosion resistance. c) The clamp has the advantages of simple installation, No special tools needed, and one person can finish the whole installation. d) The formed wire inner and outer layer components are designed to transfer axial tensile loads and distribute radial compressive forces over the surface in contact with OPGW to minimize effects on the central core and internal optical fibers. e) Once installed, the structural reinforcing rods and formed dead-end components may be removed and reinstalled once for repositioning purposes. DO NOT reuse after this initial installation. The hardware may be reused as desired if in good condition. DO NOT modify any component. f) Better seismic performance, To extend the system lifetime. 2.Components:

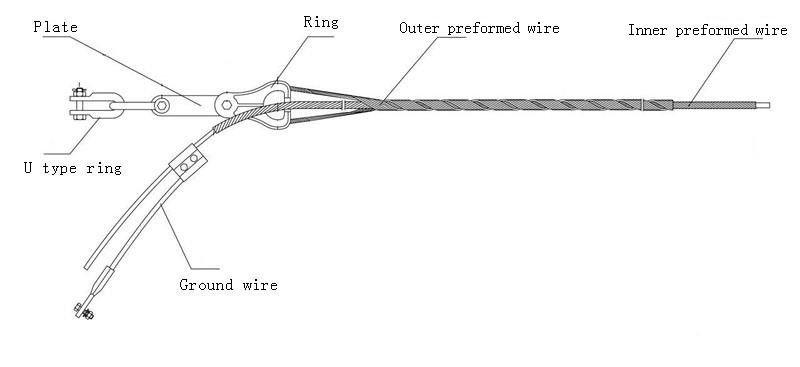

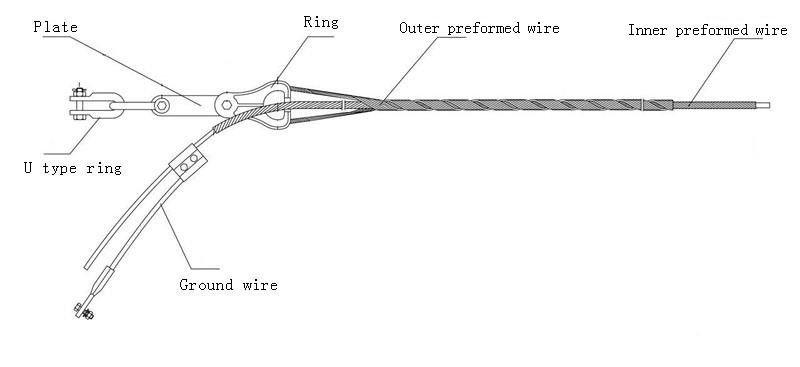

1.Specification: a) There is a large contact area between the wire clamp and the conducting wires, The stress distribution is uniform, No stress concentration point, Make sure the fiber optic cable is well protected. b) High-quality aluminum clad material, To improve the mechanical properties of the clamp and corrosion resistance. c) The clamp has the advantages of simple installation, No special tools needed, and one person can finish the whole installation. d) The formed wire inner and outer layer components are designed to transfer axial tensile loads and distribute radial compressive forces over the surface in contact with OPGW to minimize effects on the central core and internal optical fibers. e) Once installed, the structural reinforcing rods and formed dead-end components may be removed and reinstalled once for repositioning purposes. DO NOT reuse after this initial installation. The hardware may be reused as desired if in good condition. DO NOT modify any component. f) Better seismic performance, To extend the system lifetime. 2.Components:  a) Inner/Outer performed wire: Aluminum Covered Steel with Grit Applied b) Thimble Clevis(Ring): Galvanized Ductile Iron c) Extension Link(Plate): Extension Link & Pin are galvanized steel or galvanized ductile iron. A stainless steel cotter key is provided to capture the pin d) Anchor Shackle(U-type Ring): Galvanized steel forging e) Grounding Wire Assembly(Option): Aluminum conductor with aluminum compatible lug

a) Inner/Outer performed wire: Aluminum Covered Steel with Grit Applied b) Thimble Clevis(Ring): Galvanized Ductile Iron c) Extension Link(Plate): Extension Link & Pin are galvanized steel or galvanized ductile iron. A stainless steel cotter key is provided to capture the pin d) Anchor Shackle(U-type Ring): Galvanized steel forging e) Grounding Wire Assembly(Option): Aluminum conductor with aluminum compatible lug  3.Holding Strength:

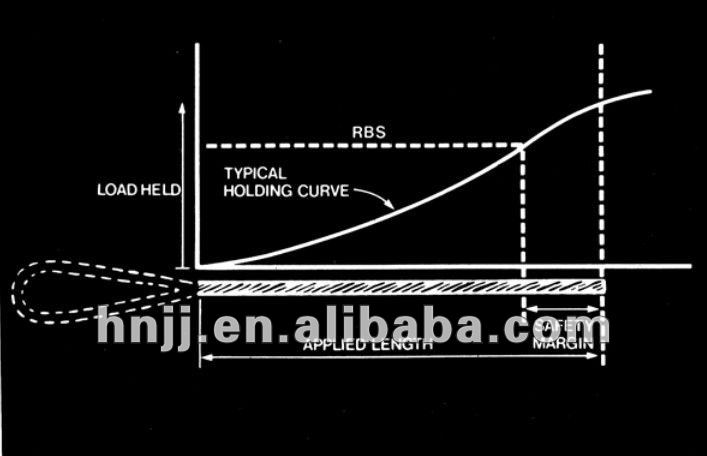

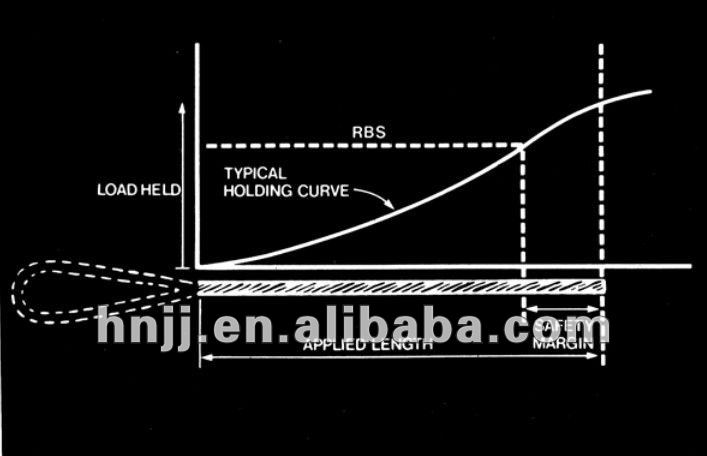

3.Holding Strength:  Typical holding strength curve illustrates that the Holding Strength and the Applied Length are not proportional. A safety factor of approximately one pitch length is designed into PREFORMED dead-ends. 4.Construction Site:

Typical holding strength curve illustrates that the Holding Strength and the Applied Length are not proportional. A safety factor of approximately one pitch length is designed into PREFORMED dead-ends. 4.Construction Site:  5.Productivity:

5.Productivity:

6.Packaging:

6.Packaging:  7.Delivery:

7.Delivery:  8.Facility:

8.Facility:

9.Certification:

9.Certification:

b. Competitive Price

c. Simple Installation

d. Good Corrosion Resistance

e. Best Service

1.Specification: a) There is a large contact area between the wire clamp and the conducting wires, The stress distribution is uniform, No stress concentration point, Make sure the fiber optic cable is well protected. b) High-quality aluminum clad material, To improve the mechanical properties of the clamp and corrosion resistance. c) The clamp has the advantages of simple installation, No special tools needed, and one person can finish the whole installation. d) The formed wire inner and outer layer components are designed to transfer axial tensile loads and distribute radial compressive forces over the surface in contact with OPGW to minimize effects on the central core and internal optical fibers. e) Once installed, the structural reinforcing rods and formed dead-end components may be removed and reinstalled once for repositioning purposes. DO NOT reuse after this initial installation. The hardware may be reused as desired if in good condition. DO NOT modify any component. f) Better seismic performance, To extend the system lifetime. 2.Components:

1.Specification: a) There is a large contact area between the wire clamp and the conducting wires, The stress distribution is uniform, No stress concentration point, Make sure the fiber optic cable is well protected. b) High-quality aluminum clad material, To improve the mechanical properties of the clamp and corrosion resistance. c) The clamp has the advantages of simple installation, No special tools needed, and one person can finish the whole installation. d) The formed wire inner and outer layer components are designed to transfer axial tensile loads and distribute radial compressive forces over the surface in contact with OPGW to minimize effects on the central core and internal optical fibers. e) Once installed, the structural reinforcing rods and formed dead-end components may be removed and reinstalled once for repositioning purposes. DO NOT reuse after this initial installation. The hardware may be reused as desired if in good condition. DO NOT modify any component. f) Better seismic performance, To extend the system lifetime. 2.Components:  3.Holding Strength:

3.Holding Strength:  Typical holding strength curve illustrates that the Holding Strength and the Applied Length are not proportional. A safety factor of approximately one pitch length is designed into PREFORMED dead-ends. 4.Construction Site:

Typical holding strength curve illustrates that the Holding Strength and the Applied Length are not proportional. A safety factor of approximately one pitch length is designed into PREFORMED dead-ends. 4.Construction Site:  5.Productivity:

5.Productivity:

6.Packaging:

6.Packaging:  7.Delivery:

7.Delivery:  8.Facility:

8.Facility:

9.Certification:

9.Certification:

Related Keywords

Related Keywords