Dredge Pump

- Delivery Time:

- 60 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

Features: 1. Structure suitable for dredging ship: The structure of 200WN-500WN type pumps are single-casing, single-stage, single-suction, cantilever and horizontal. According to the connection with the gear box, two structures can be offered: self-carrying bracket and pump-box assembly. The lubrication for the bracket is grease or thin oil. The structure of 600WN-1000WN type pumps are double-casing, single-stage, single suction, cantilever and horizontal. It has self-carrying bracket. Lubrication is forced thin oil lubricating. The double-casing design can ensure the liner can work till it is worn out, and if the liner crack, water can not enter into the pump.  2. Easy to Disassembly and Installation, Convenient Maintenance: WN type pump adopts front-disassembly structure in favor of easy disassembly and maintenance. Also it is equipped with special disassembly tools for each different part according to each parts features. The standard trapezoidal quadruple thread is adopted to connect the impeller and shaft, which not only transmits strong torque but also is easy to disassembly.

2. Easy to Disassembly and Installation, Convenient Maintenance: WN type pump adopts front-disassembly structure in favor of easy disassembly and maintenance. Also it is equipped with special disassembly tools for each different part according to each parts features. The standard trapezoidal quadruple thread is adopted to connect the impeller and shaft, which not only transmits strong torque but also is easy to disassembly.  3. Good Performance on NPSH: The good NPSH performance of WN type pump ensures the strong suction ability as well as deeper dredging depth and denser dredging concentration. 4. Good Wear-resistant Performance, Long Service Time of Wet Parts: Wet parts of this kind of dredging pump-impeller, liner and front & back liner plate are adapted anti-wear cast iron alloy whose hardness is more than 58HRC, who has both strong anti-attack feature and higher resistance wear and resistance abrasion features. The hardness of A31 material that is researched and tested successfully by Kingda can research 70HRC. 5. Reliable Shaft Sealing Without Leakage: The shaft of 200-500WN dredging pump uses the mechanical sealing or stuffing sealing or mechanical-stuffing compound sealing. The shaft of 600-1000 WN dredging pump adopts spiral sleeve L (shape) rubber sealing device that consists of three L sealing ring and one special thread shaft sleeve.

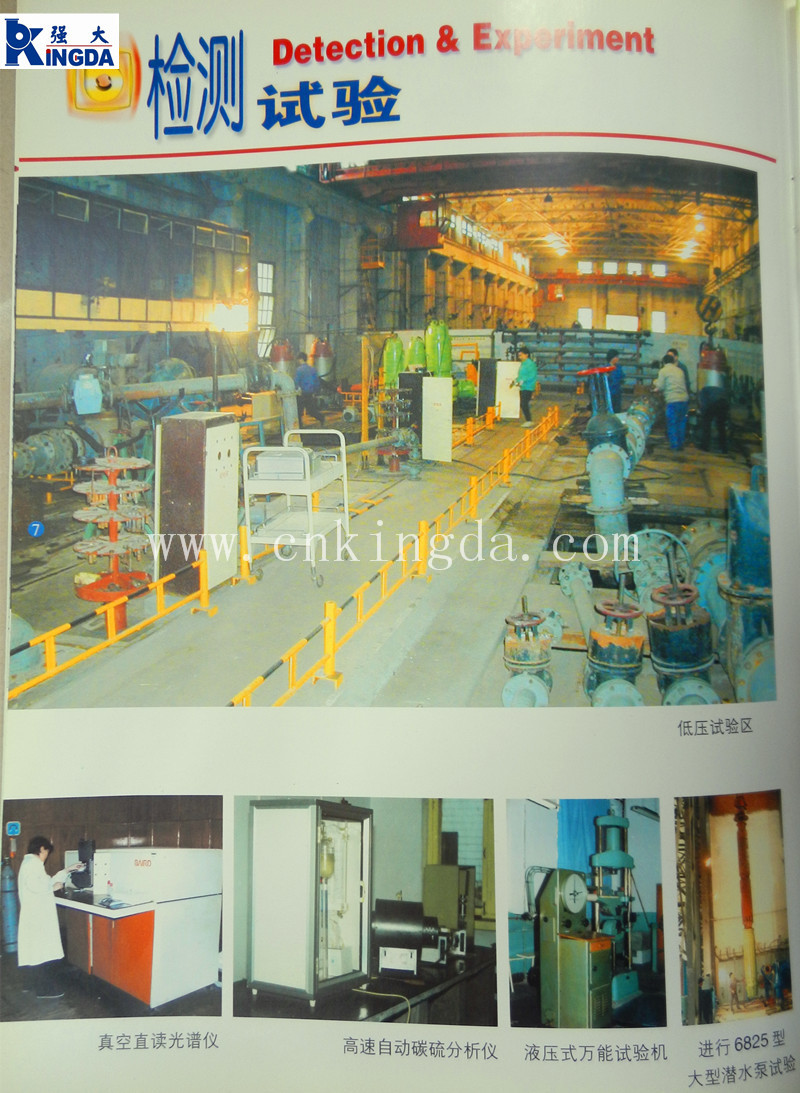

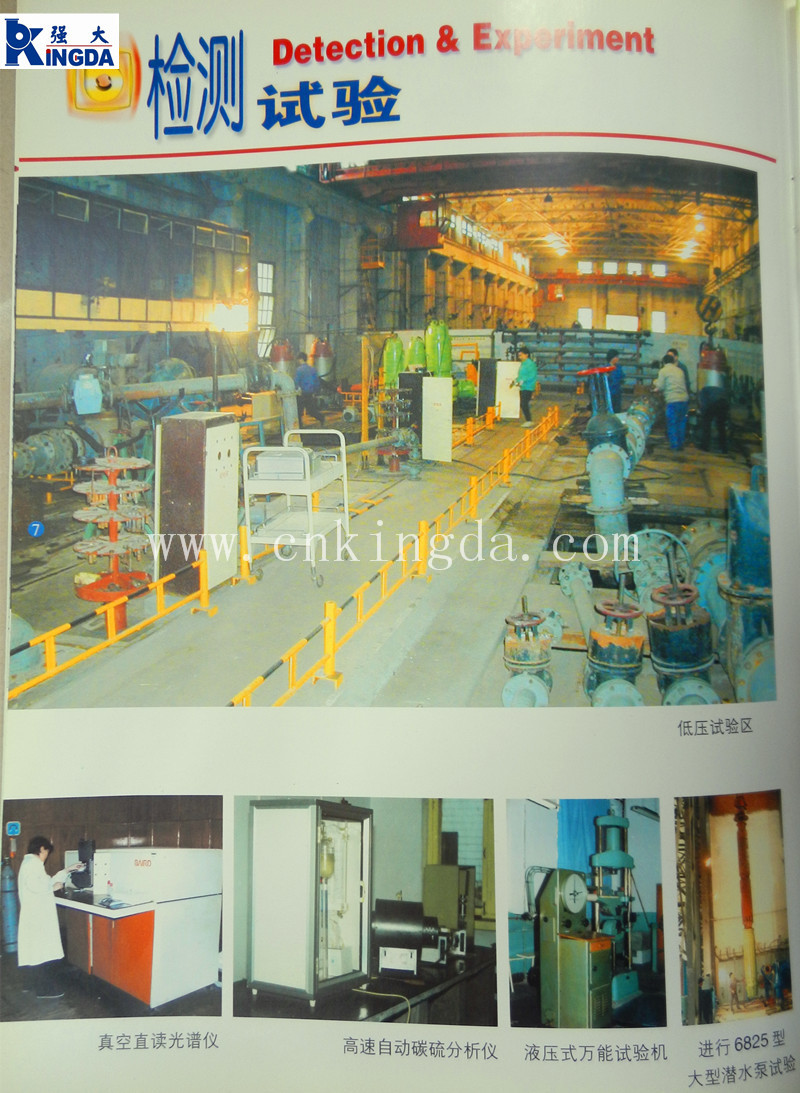

3. Good Performance on NPSH: The good NPSH performance of WN type pump ensures the strong suction ability as well as deeper dredging depth and denser dredging concentration. 4. Good Wear-resistant Performance, Long Service Time of Wet Parts: Wet parts of this kind of dredging pump-impeller, liner and front & back liner plate are adapted anti-wear cast iron alloy whose hardness is more than 58HRC, who has both strong anti-attack feature and higher resistance wear and resistance abrasion features. The hardness of A31 material that is researched and tested successfully by Kingda can research 70HRC. 5. Reliable Shaft Sealing Without Leakage: The shaft of 200-500WN dredging pump uses the mechanical sealing or stuffing sealing or mechanical-stuffing compound sealing. The shaft of 600-1000 WN dredging pump adopts spiral sleeve L (shape) rubber sealing device that consists of three L sealing ring and one special thread shaft sleeve.  Company Information Shijiazhuang Kingda Pump Industry Group Co., Ltd is the largest manufacturer of slurry pump, sewage pump, clear water pump and petrochemical pump in China, which includes scientific reasearch, design and manufacture. At present, Kingda Pump Group owns 12 subsidiaries, our anual production capacity is 13000 tons. We can supply all kinds of pumps and systems, and other products such as valve, cyslone, control starter to enterprises and fields whcih include environmental protection, wastewater treatment, supply and drainage for city plants, different kiinds of water conservancy projects, farm irrigation, metallurgical, mining, thermal power plant, coal, petrochemiccal, construction, FGD, etc. The products as natioonal fine quality products are sold well to the whole Chinese market with top market occupy rate. International market is beiing enlarged and products had been exported to more than 50 countries and districts such as North America, South America, Europe, Africa, South East Asia and Middle East.

Company Information Shijiazhuang Kingda Pump Industry Group Co., Ltd is the largest manufacturer of slurry pump, sewage pump, clear water pump and petrochemical pump in China, which includes scientific reasearch, design and manufacture. At present, Kingda Pump Group owns 12 subsidiaries, our anual production capacity is 13000 tons. We can supply all kinds of pumps and systems, and other products such as valve, cyslone, control starter to enterprises and fields whcih include environmental protection, wastewater treatment, supply and drainage for city plants, different kiinds of water conservancy projects, farm irrigation, metallurgical, mining, thermal power plant, coal, petrochemiccal, construction, FGD, etc. The products as natioonal fine quality products are sold well to the whole Chinese market with top market occupy rate. International market is beiing enlarged and products had been exported to more than 50 countries and districts such as North America, South America, Europe, Africa, South East Asia and Middle East.

2. Easy to Disassembly and Installation, Convenient Maintenance: WN type pump adopts front-disassembly structure in favor of easy disassembly and maintenance. Also it is equipped with special disassembly tools for each different part according to each parts features. The standard trapezoidal quadruple thread is adopted to connect the impeller and shaft, which not only transmits strong torque but also is easy to disassembly.

2. Easy to Disassembly and Installation, Convenient Maintenance: WN type pump adopts front-disassembly structure in favor of easy disassembly and maintenance. Also it is equipped with special disassembly tools for each different part according to each parts features. The standard trapezoidal quadruple thread is adopted to connect the impeller and shaft, which not only transmits strong torque but also is easy to disassembly.  3. Good Performance on NPSH: The good NPSH performance of WN type pump ensures the strong suction ability as well as deeper dredging depth and denser dredging concentration. 4. Good Wear-resistant Performance, Long Service Time of Wet Parts: Wet parts of this kind of dredging pump-impeller, liner and front & back liner plate are adapted anti-wear cast iron alloy whose hardness is more than 58HRC, who has both strong anti-attack feature and higher resistance wear and resistance abrasion features. The hardness of A31 material that is researched and tested successfully by Kingda can research 70HRC. 5. Reliable Shaft Sealing Without Leakage: The shaft of 200-500WN dredging pump uses the mechanical sealing or stuffing sealing or mechanical-stuffing compound sealing. The shaft of 600-1000 WN dredging pump adopts spiral sleeve L (shape) rubber sealing device that consists of three L sealing ring and one special thread shaft sleeve.

3. Good Performance on NPSH: The good NPSH performance of WN type pump ensures the strong suction ability as well as deeper dredging depth and denser dredging concentration. 4. Good Wear-resistant Performance, Long Service Time of Wet Parts: Wet parts of this kind of dredging pump-impeller, liner and front & back liner plate are adapted anti-wear cast iron alloy whose hardness is more than 58HRC, who has both strong anti-attack feature and higher resistance wear and resistance abrasion features. The hardness of A31 material that is researched and tested successfully by Kingda can research 70HRC. 5. Reliable Shaft Sealing Without Leakage: The shaft of 200-500WN dredging pump uses the mechanical sealing or stuffing sealing or mechanical-stuffing compound sealing. The shaft of 600-1000 WN dredging pump adopts spiral sleeve L (shape) rubber sealing device that consists of three L sealing ring and one special thread shaft sleeve.  Company Information Shijiazhuang Kingda Pump Industry Group Co., Ltd is the largest manufacturer of slurry pump, sewage pump, clear water pump and petrochemical pump in China, which includes scientific reasearch, design and manufacture. At present, Kingda Pump Group owns 12 subsidiaries, our anual production capacity is 13000 tons. We can supply all kinds of pumps and systems, and other products such as valve, cyslone, control starter to enterprises and fields whcih include environmental protection, wastewater treatment, supply and drainage for city plants, different kiinds of water conservancy projects, farm irrigation, metallurgical, mining, thermal power plant, coal, petrochemiccal, construction, FGD, etc. The products as natioonal fine quality products are sold well to the whole Chinese market with top market occupy rate. International market is beiing enlarged and products had been exported to more than 50 countries and districts such as North America, South America, Europe, Africa, South East Asia and Middle East.

Company Information Shijiazhuang Kingda Pump Industry Group Co., Ltd is the largest manufacturer of slurry pump, sewage pump, clear water pump and petrochemical pump in China, which includes scientific reasearch, design and manufacture. At present, Kingda Pump Group owns 12 subsidiaries, our anual production capacity is 13000 tons. We can supply all kinds of pumps and systems, and other products such as valve, cyslone, control starter to enterprises and fields whcih include environmental protection, wastewater treatment, supply and drainage for city plants, different kiinds of water conservancy projects, farm irrigation, metallurgical, mining, thermal power plant, coal, petrochemiccal, construction, FGD, etc. The products as natioonal fine quality products are sold well to the whole Chinese market with top market occupy rate. International market is beiing enlarged and products had been exported to more than 50 countries and districts such as North America, South America, Europe, Africa, South East Asia and Middle East.