TC fiber cement board line (full automatic)

- Delivery Time:

- 90 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Hebei, China (Mainland) |

|---|

Product Description

Product Description

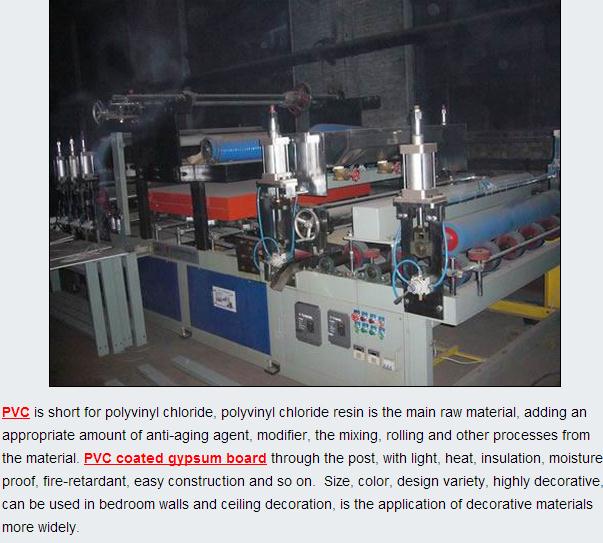

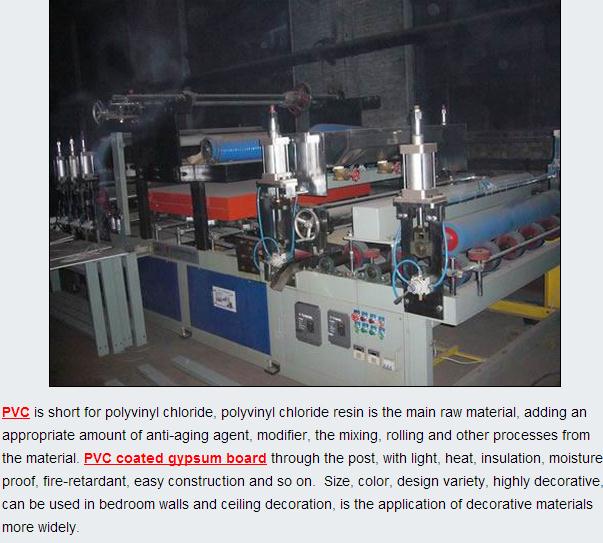

1. Brief introduction: Fiber cement board is a new type light-weight and high-strength material with good fireproof and heat insulation performances. It is made of siliceous (main component is SiO2), cement and reinforced material. It is made in such procedures: making slurry, shaping, pressing, curing& maintenance, drying, sanding etc. The fiber cement board production line which is different from traditional building material production line. It has higher requirements on techniques and equipments. The board can be fabricated in the waqy of sawing, drilling, nailing etc. After decoration on the surface, it can be used widely on building inner wall, ceiling ... 2. Fiber cement board specification: Length: 2400-2440mm, Width: 1200-1220mm, Thickness: 4-30mm 3. Production technology: Fiber cement board production line adopts Flowing Slurry method and Hatchek Process, with latest technology as well as simple operation. 4. Production line type: Control system: PLC full automatic control system; Autoclaved system: After the board is conveyed into cutoclave, it takes about 16 hours' treatment of high temperature and high pressure saturated steam curing. Generally, the system of autoclaved maintenance is 3 hours' temperature rise, 10 hours' constant temperature, 3 hours' cooling and the constant pressure is 1.2 MPa; Fuel: natural gas, coal, heavy oil, diesel etc. 5. Main procedures of fiber cement board production line: Slurry treatment system--- Slurry making system--- Board shaping system--- Stacking and demoulding system--- Autoclave and curing system--- Drying system--- Sanding and grinding section--- Final processing and storage 6. Raw material and fuel consumption: 1). cement: comply with the quality requirements of C42.5 ordinary Portland cement in GB175-2000 "Portland cement, ordinary Portland cement" standard. Shall not be used miced with coal, charcoal for aids and shale, coal gangue for ordinary Portland cement admixtures; 2). Hydrated lime powder: The lime should be complying with JC/T621-1996" silicate building product with lime". It requires efficient (CaO+MgO)>80%, content of MgO should be less than 5%, fineness 200 mesh sieve is less than 5%; 3). silica powder: SiO2>95% Al2O3<5% Fineness 300 mesh, sieve<5% 4). paper fiber: Unbleached Kraft softwood pulp paperboard, slurry degree is 20~55° SR 5). others Our fiber cement board production line can produce both non-asbestos and asbestos fiber cement board. We have professional engineers to design the proposal according to our client's requirements. We can also provide a series of technical services such as equipment installation, commissioning, job training etc.

Related Keywords

Related Keywords